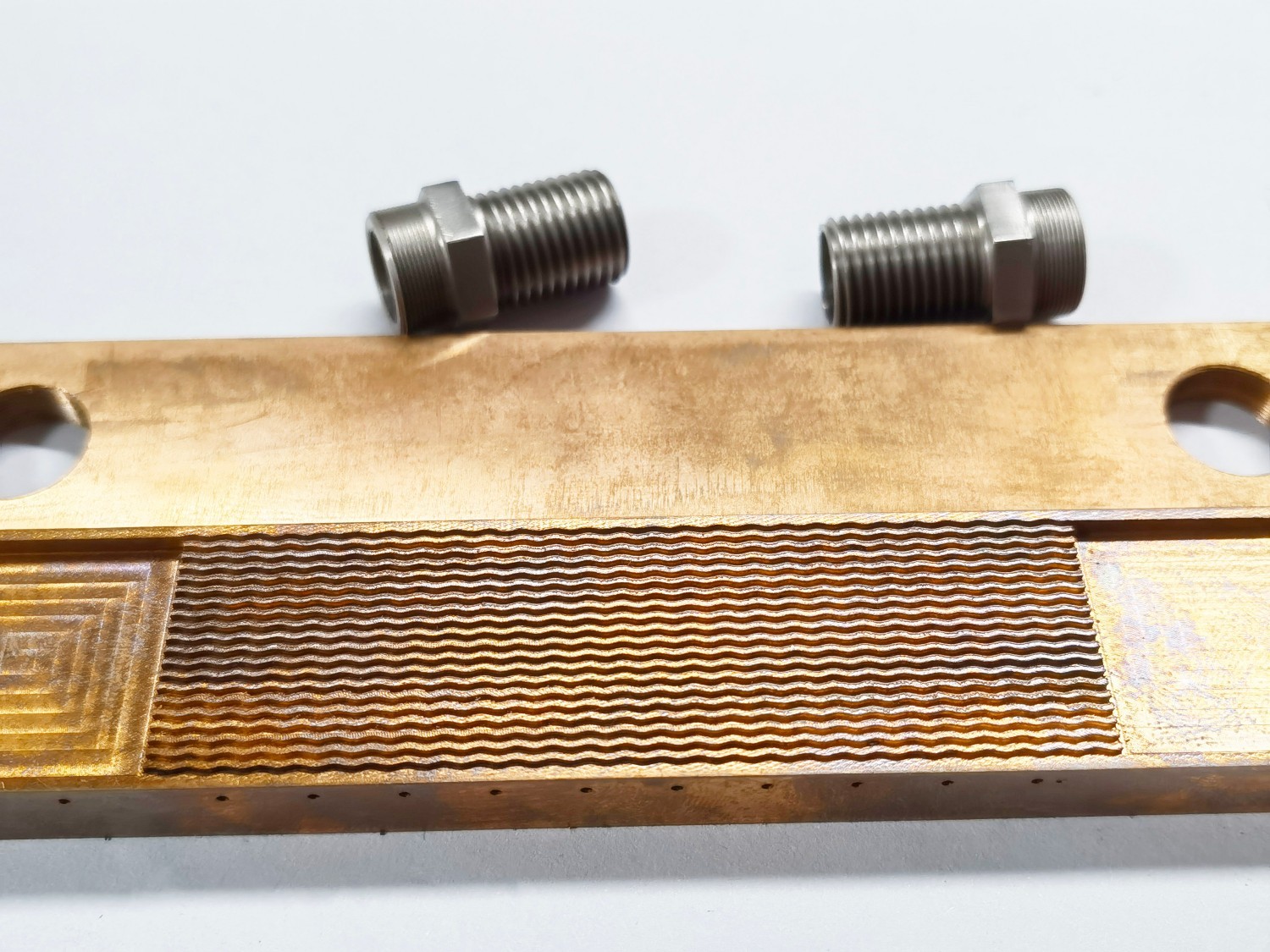

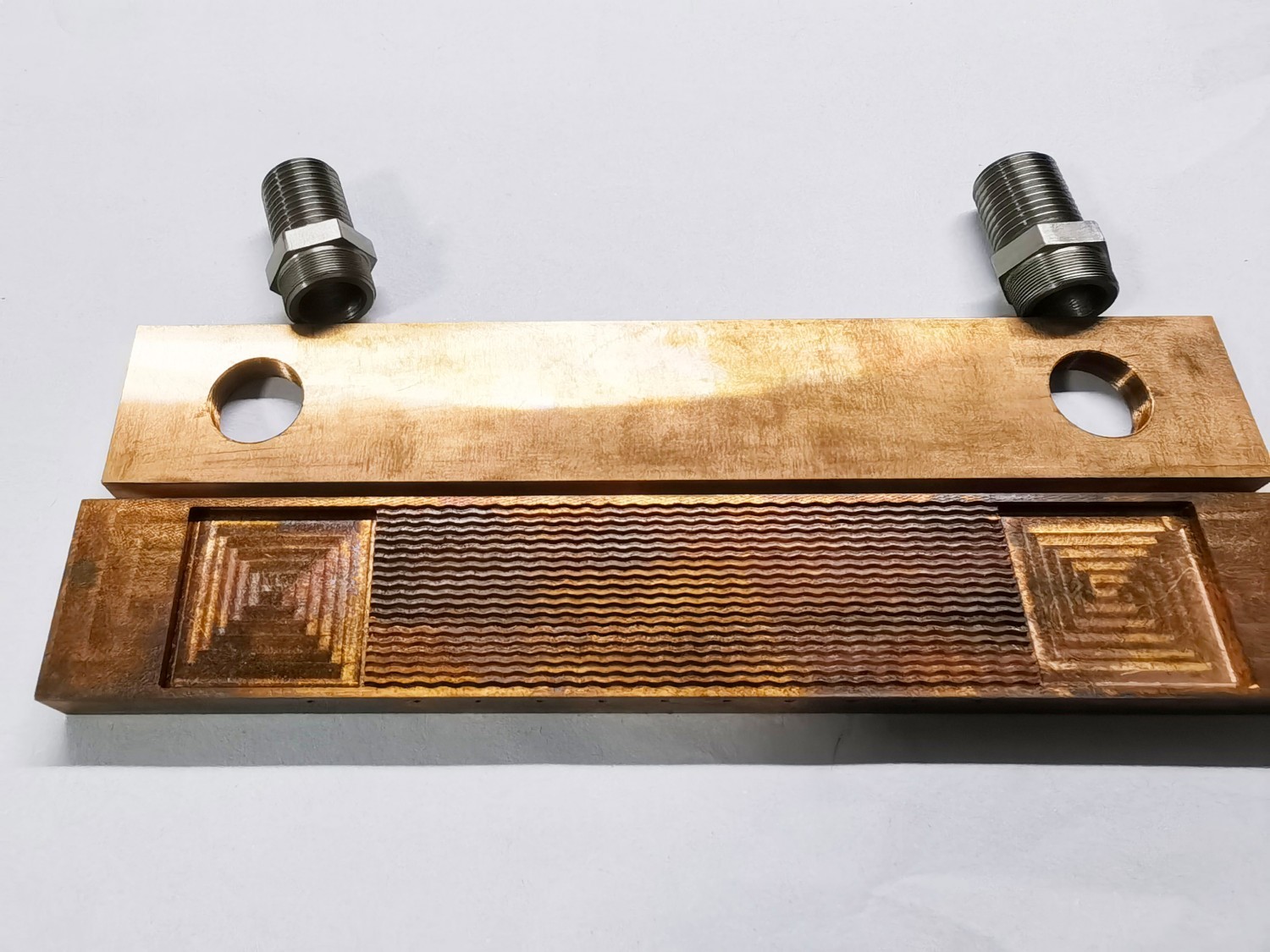

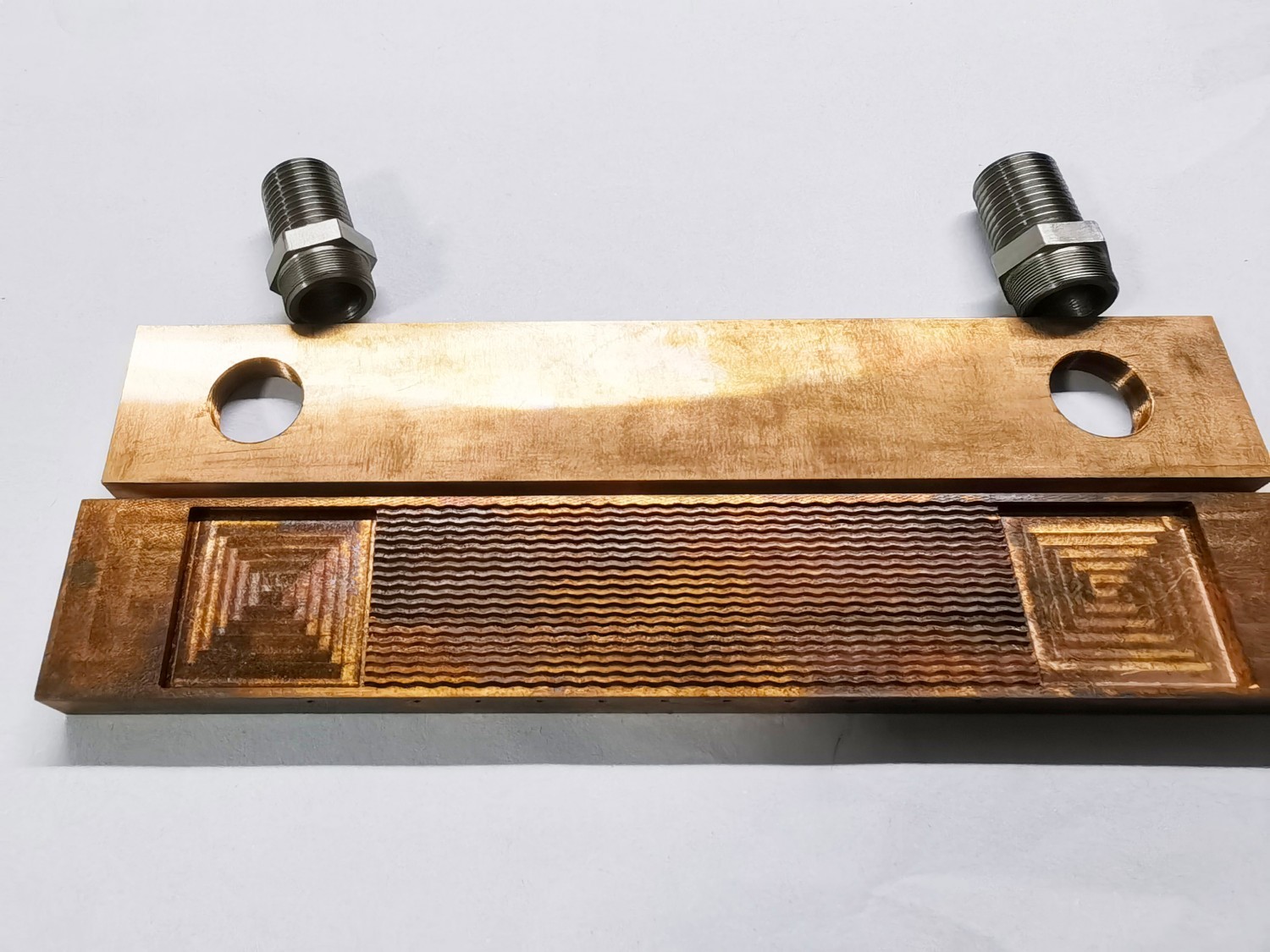

Heat Exchanger Microchannels / Customizable Orders / Factory Direct Supply / Precision Etching

Copper has a much higher thermal conductivity than most other metals, allowing it to quickly transfer heat generated by electronic components or other devices, effectively preventing overheating. Its thermal conductivity is several times that of materials like aluminum and steel, significantly enhancing heat dissipation efficiency. Copper has high mechanical strength and stability, allowing it to operate in harsh environments for extended periods, ensuring the safety and reliability of electronic devices. Copper naturally has corrosion resistance properties, especially after surface treatment, which makes it more effective at resisting oxidation and corrosion, adapting to various environmental conditions and extending the lifespan of heat dissipation components. Copper has a relatively low coefficient of thermal expansion, meaning it deforms less with temperature changes, thus maintaining good dimensional stability in both high and low-temperature environments. Copper is easy to process and can be made into various shapes of heat dissipation plates through cutting, stamping, milling, etc., to meet the needs of different electronic devices or systems. Especially with metal etching processing technology, complex heat dissipation structures can be achieved.

Key Words:

Table Parameter

| Product Name | Metal Heat Dissipation Plate |

| Processing Methods | Common methods include metal etching, laser cutting, water jet cutting, CNC machining, milling, turning, heat treatment, and surface treatment. |

| Material | Mainly SUS304, SUS316 stainless steel etching, and all copper materials, copper alloys, and molybdenum sheets can be etched. |

| Material Thickness | Ideal thickness range: 0.05mm - 0.5mm. Currently, the factory can process materials ranging from 0.02mm to 2.0mm. Thicker materials require longer etching time and higher cost, while ultra-thin materials also involve higher processing costs and special handling for deformation prevention. |

| Shape | Almost any shape is possible. The minimum opening and groove size depend on the material thickness. Thicker plates require larger gaps for opening. Complex shapes can also be etched without additional cost. |

| Precision Control | Our etching processing can achieve concave and convex effects that stamping, cutting, or CNC cannot, such as logos, brand marks, and strong three-dimensional patterns, with high precision. |

| Tolerance Range | The processing accuracy can be around 10% of the material thickness, e.g., for 0.1mm thick stainless steel, the achievable accuracy is +/- 0.01mm. |

| Packaging | Custom packaging based on order. |

| Minimum Order Quantity | Confirmed based on specific needs. |

| Lead Time | Generally 5-15 days for mass production, with expedited options for urgent orders. |

| Price | Pricing is determined by factors including material, processing method, and order quantity. |

Application Description

(1) Electronic Products

1.Computer Processors and Graphics Cards: Copper heat dissipation plates are commonly used in the heat sinks of high-performance computer CPUs and GPUs. They help quickly transfer heat generated by the processor to the heat sink or radiator, preventing overheating.

2.LED Lighting: LED lights require effective heat dissipation, and copper heat dissipation plates are widely used in LED lighting systems to ensure stable operating temperatures and prolong the lifespan of the lights.

3.Battery Management Systems: In high-power devices like electric vehicles or energy storage systems, copper heat dissipation plates help dissipate heat from battery modules, maintaining the battery within a proper temperature range to ensure performance and safety.

(2) Consumer Electronics

1.Smartphones, Tablets, and Laptops: Copper heat dissipation plates help dissipate heat from processors, memory, and other components in smartphones, tablets, and laptops, preventing overheating and maintaining stable performance.

2.TVs and Monitors: In high-end televisions and monitors, copper heat dissipation plates efficiently disperse heat from electronic components, ensuring the devices operate normally.

(3) Automotive Electronics

1.Electric Vehicles: Copper heat dissipation plates are used in the battery packs, electric motors, and inverters of electric vehicles to prevent overheating and performance degradation.

2.In-Car Electronic Systems: Systems like in-car navigation, entertainment, and driver assistance also use copper heat dissipation plates to maintain proper working temperatures.

(4) Communication Devices

1.Base Stations and Communication Equipment: Copper heat dissipation plates are used in communication base stations, routers, and radio devices to dissipate heat from electronic components, ensuring the devices do not overheat under heavy load.

(5) Power Electronics

1.Power Electronic Devices: In equipment like inverters, variable frequency drives, and power regulation systems, copper heat dissipation plates effectively transfer heat, ensuring stable operation of high-power electronic devices.

Questions and Answers

| 1.How are samples charged? Most products are available as free samples, but custom or high-cost products may require sample charges. Bulk orders are priced per unit. |

| 2.Do you support custom processing? Yes, we can customize products according to customer materials, technical requirements, and drawings. |

| 3.What is the delivery time? For bulk orders, processing generally takes 5-15 days. We can expedite for urgent orders. |

| 4.What are your payment methods? Since this is a custom product, full prepayment is required. We accept: Letter of Credit (L/C) Telegraphic Transfer (T/T) PayPal (for small orders) Western Union (for certain countries) Alipay/WeChat Pay (for some countries) Bank Transfer |

| 5.What happens if the products are defective? If there are any issues with the products, please contact us, and we will replace the products in your next order at no additional cost. |

| 6.How is shipping cost calculated? Shipping fees are calculated based on weight, volume, destination, and shipping method (air freight, sea freight, express delivery). Provide your order details, and we will offer a shipping quote. |

Factory Description

We have a full set of etching production equipment and mature processing technology. We can manufacture products in any shape with mesh sizes as small as 0.1mm, according to your requirements.

Our Advantage

Factory Direct Shipping

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Experienced Design and Manufacturing Team

We work closely with customers from the design phase to help avoid potential product flaws, ensuring both the functionality and design meet expectations.

Excellent Supply Chain Management

We can quickly adjust production schedules to meet your urgent deadlines, whether it's for large bulk orders or smaller rush orders.

OEM & ODM Support

We offer the option to print your logo or other customizations.

Strict Quality Control

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Certificate

Related Products