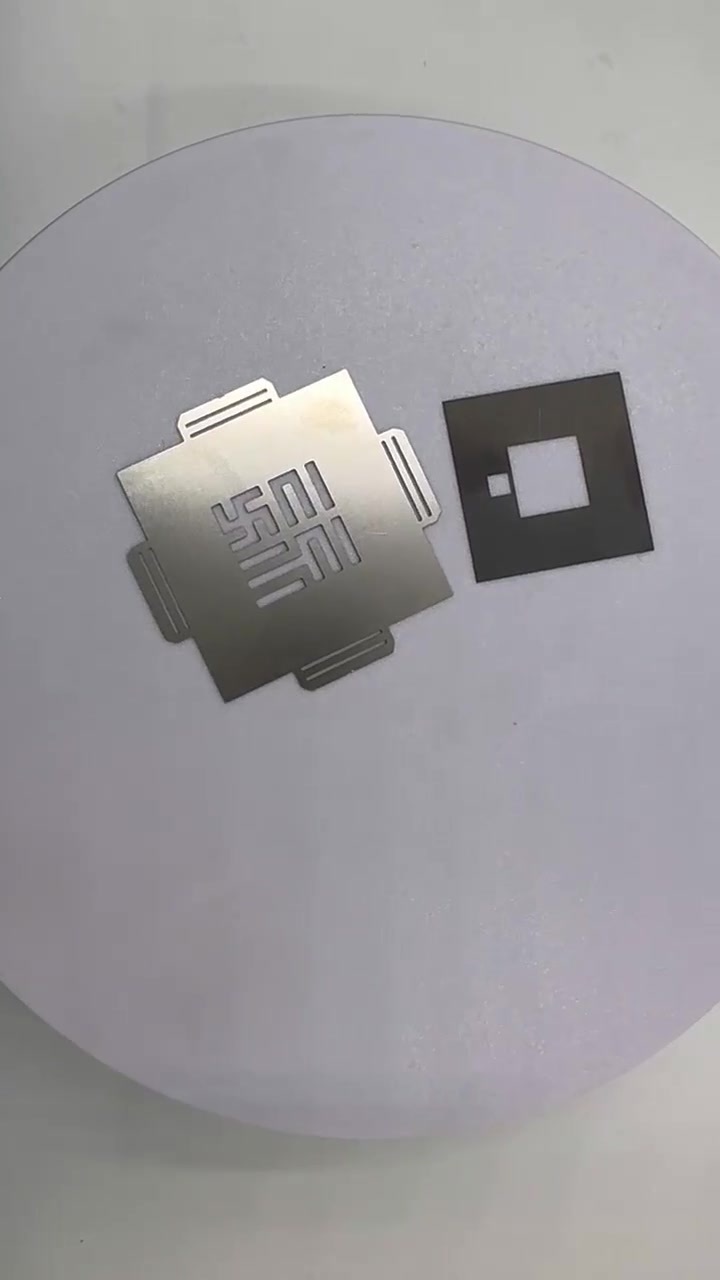

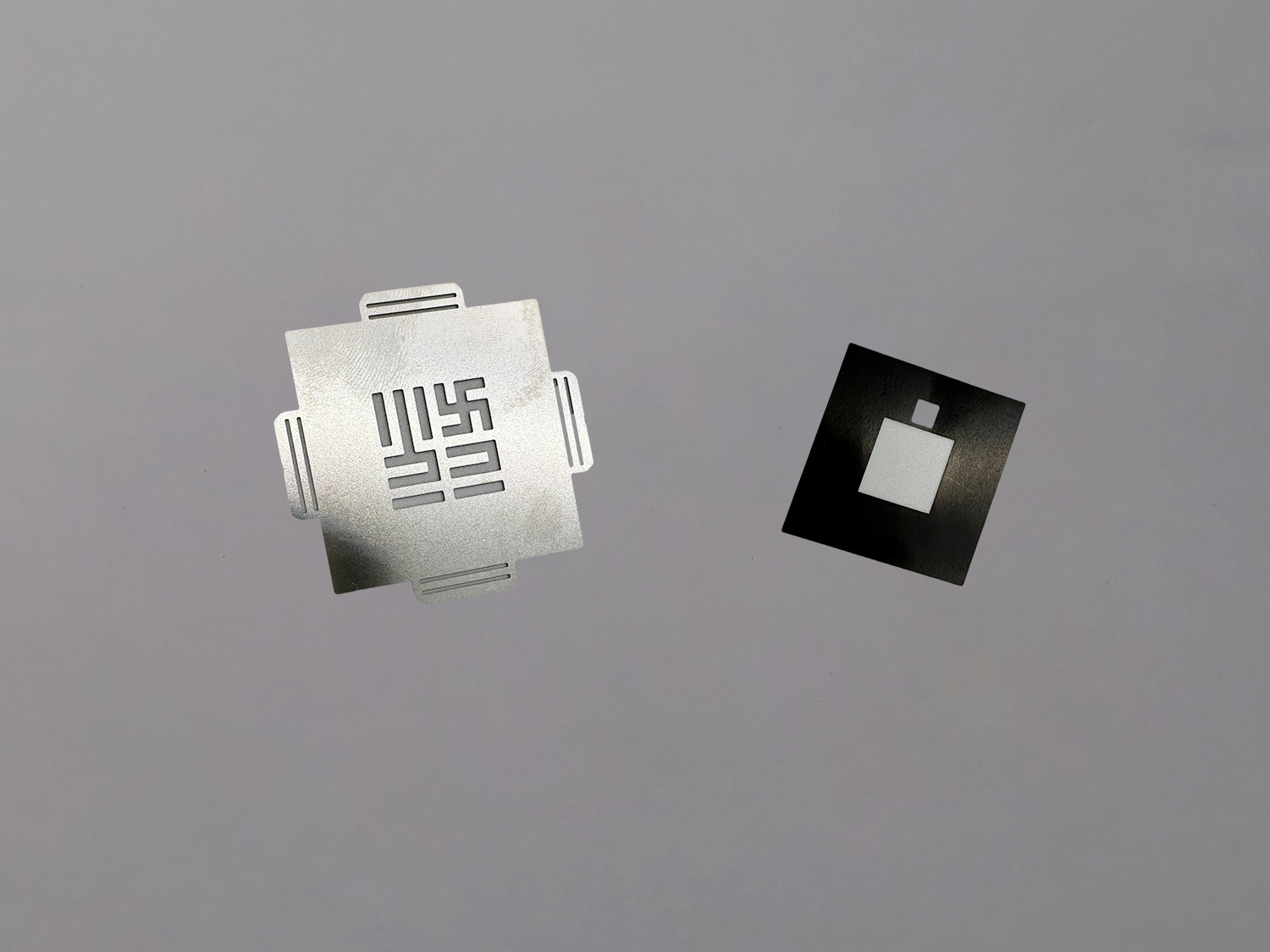

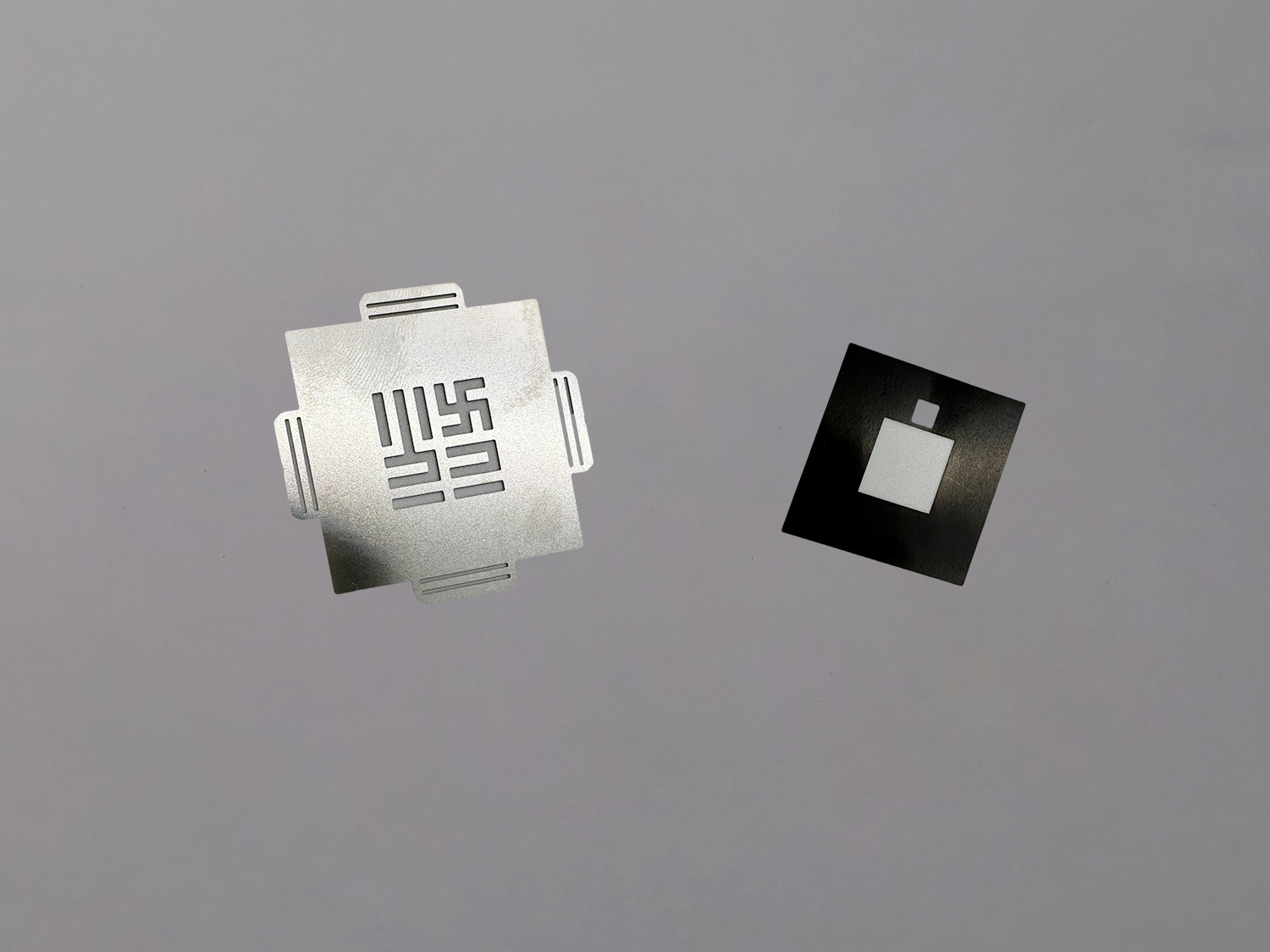

Stainless Steel Gaskets/ Customizable Orders / Factory Direct Supply / Precision Etching

Laser-cut thin stainless steel gaskets offer high precision, smooth cutting edges, high production efficiency, and versatility in material compatibility. This advanced cutting technology not only ensures high-quality gaskets but also meets the demand for customization and small-batch production. These gaskets are widely used in industries like automotive, machinery, electronics, and chemical processing to ensure sealing performance and operational reliability.

Category:

Key Words:

Table Parameter

| Product Name | Stainless Steel Gaskets |

| Material | Primarily SUS304, SUS316 stainless steel (etched), |

| Material Thickness | along with various copper materials, copper alloys, and molybdenum materials. |

| - Thin Material (1-3mm) | Using a fiber laser cutting machine (1kW or higher power), we can cut hundreds of small parts per hour, depending on part complexity. Cutting speed ranges from 1-3 meters per minute, completing 10-100 parts per hour depending on size and shape. For ultra-thin materials, laser cutting may cause thermal deformation, so we may recommend etching for high precision requirements. |

| - Medium Thickness (3-10mm) | For thicker materials, cutting speed slows down. For example, cutting 5mm stainless steel, the cutting speed ranges from 0.5-2 meters per minute, resulting in an hourly output of 20-50 parts. |

| - Thick Material (10mm and above) | For thicker materials like carbon steel or stainless steel above 10mm, cutting speed decreases further, with a lower output of 10-20 parts per hour, depending on laser power and material type. |

| Shape | Almost any shape can be cut. |

| Tolerance | Manufacturing precision is typically within 10% of the material thickness (e.g., +/-0.01mm for 0.1mm thick stainless steel). |

| Packaging | Customizable based on customer requests. |

| Minimum Order Quantity (MOQ) | To be determined based on specific product requirements. |

| Lead Time | Typical production cycle for bulk orders is 5-15 days. For urgent orders, please contact us for expedited production. |

| Price | Pricing is based on material type, etched material thickness, and order volume. |

Application Description

Automotive Industry

1.Engine Components: Gaskets are used between engine parts for sealing, such as cylinder head gaskets and exhaust system gaskets.

2.Braking Systems: Thin stainless steel gaskets are used in brake components and heat exchangers to ensure a secure seal and high-temperature resistance.

3.Air Conditioning Systems: Gaskets are used in compressors, condensers, and other components to maintain system integrity.

Machinery and Equipment

1.Pumps and Valves: Gaskets provide sealing at pump and valve connections to prevent leakage of liquids, gases, or other fluids.

2.Compressors and Fans: These gaskets ensure sealing at the seams, offering resistance to high pressure and temperature.

3.Hydraulic Equipment: Gaskets seal connections in hydraulic cylinders, pumps, and other components in hydraulic systems.

Industrial Equipment

1.Heat Exchangers: Gaskets are used to maintain sealing efficiency in heat exchangers, preventing leaks of cooling fluids or other media.

2.Electronics: Used in the sealing of enclosures for electrical devices to protect against water and dust ingress while providing mechanical protection.

3.Kitchen Equipment: High-temperature, corrosion-resistant gaskets for kitchen appliances like stoves, ovens, and gas burners.

Aerospace

1.Aircraft Engines: Used for sealing and protecting parts of aircraft engines to prevent contaminants from entering the engine.

2.Satellites and Spacecraft: Commonly used in components requiring airtight seals, like fuel systems and power systems.

Medical Equipment

1.Medical Instruments: Used to seal fluid or gas systems in medical devices, ensuring contamination-free and efficient operation.

2.Food Processing Equipment: Stainless steel gaskets are widely used in food machinery to maintain hygiene and sealing integrity.

Power Equipment

1.Generators and Substation Equipment: Gaskets are used in high-temperature and high-pressure environments to ensure effective sealing in power equipment.

2.High-Pressure Equipment: Used in transformers, cable connections, and other high-pressure sealing applications.

Oil & Chemical Industries

1.Oil and Gas Pipelines: Used to seal pipe connections, preventing fluid leakage while withstanding high pressures, temperatures, and corrosive environments.

2.Chemical Reactors: Gaskets ensure the sealing of chemical equipment to prevent hazardous material leakage and ensure safe operations.

Marine and Offshore Equipment

1.Marine Engines and Pipelines: Stainless steel gaskets are used to seal engine components and marine engineering equipment, offering waterproofing and corrosion resistance.

Questions and Answers

1.Do you need molds for laser cutting? No, laser cutting does not require molds, which is a key advantage over traditional methods like stamping or shearing. The laser cuts directly through the material, making it ideal for precision work, rapid prototyping, and small batch production. |

2.How are samples charged? Most of our products are available for free sampling. We also provide similar products if the exact one is not available. Custom or high-cost samples may incur a charge, but bulk orders are priced at the unit rate. |

3.What is your lead time? For bulk orders, production usually takes 5-15 days. In case of urgent orders, please discuss with us to arrange faster delivery. |

4.What payment methods do you accept? Since this is a custom product, full payment is required upfront. We accept various payment methods including: |

5.What if the products are defective? If there are any issues with the products, please contact us. We will replace the defective items in your next order at no cost. |

Factory Description

We have a full set of etching production equipment and mature processing technology. We can manufacture products in any shape with mesh sizes as small as 0.1mm, according to your requirements.

Our Advantage

Factory Direct Shipping

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Experienced Design and Manufacturing Team

We work closely with customers from the design phase to help avoid potential product flaws, ensuring both the functionality and design meet expectations.

Excellent Supply Chain Management

We can quickly adjust production schedules to meet your urgent deadlines, whether it's for large bulk orders or smaller rush orders.

OEM & ODM Support

We offer the option to print your logo or other customizations.

Strict Quality Control

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Certificate

Related Products