custom Laminated shims /Factory Direct/Material Options Available

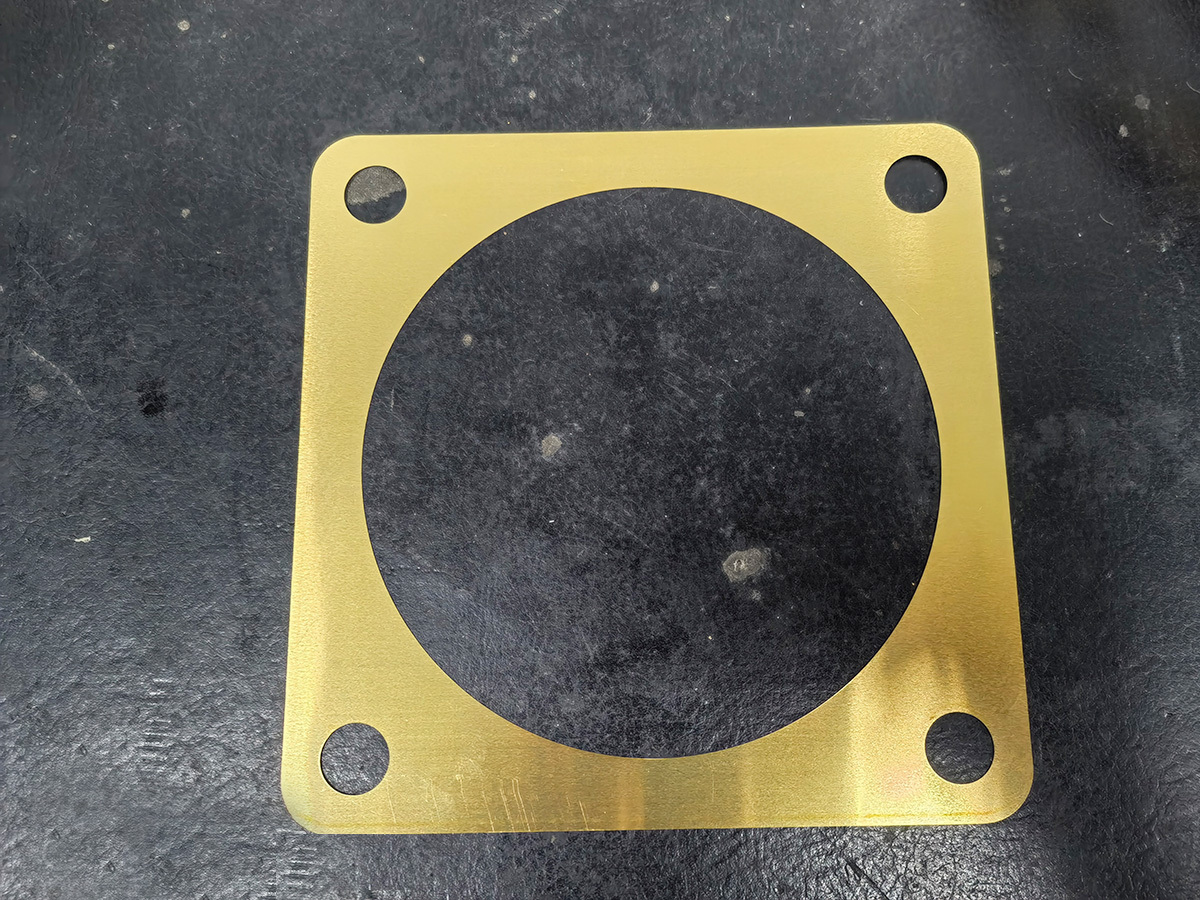

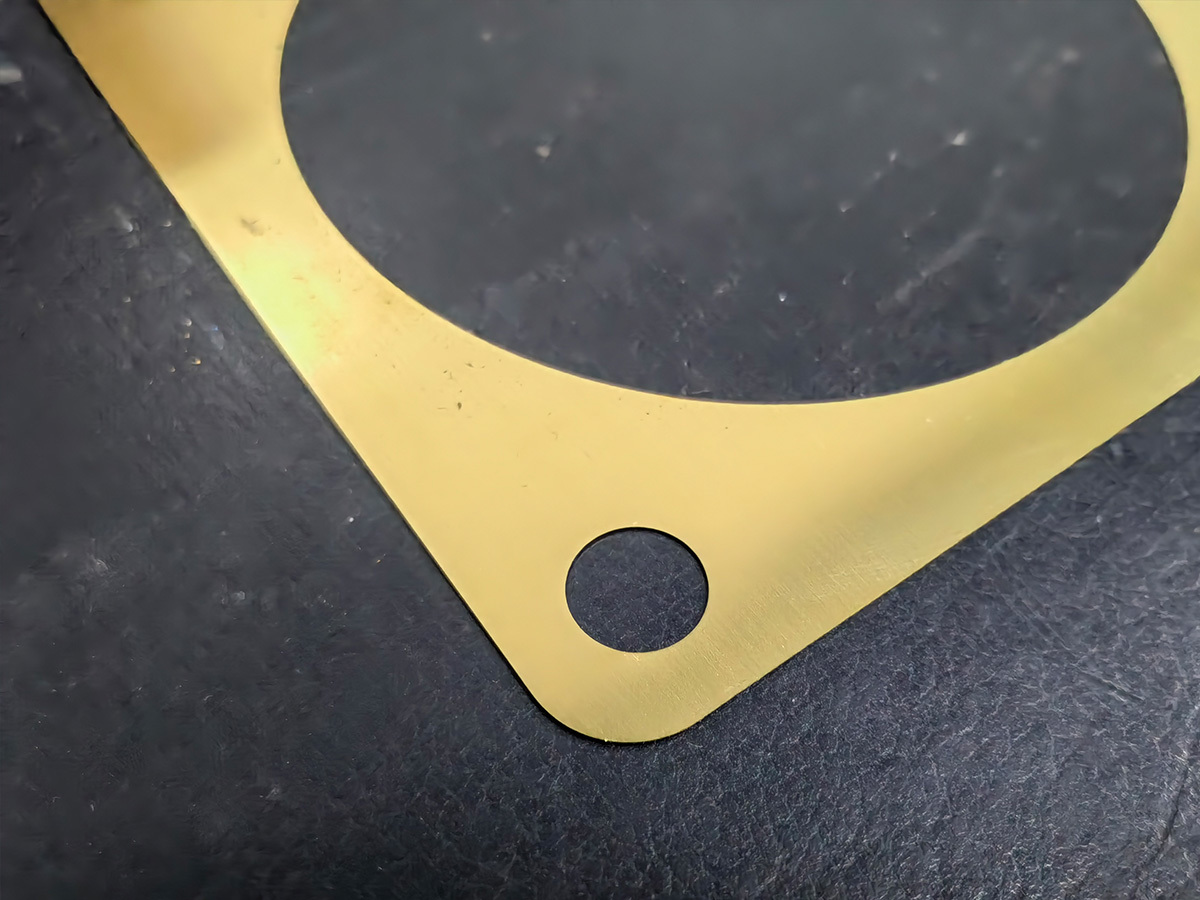

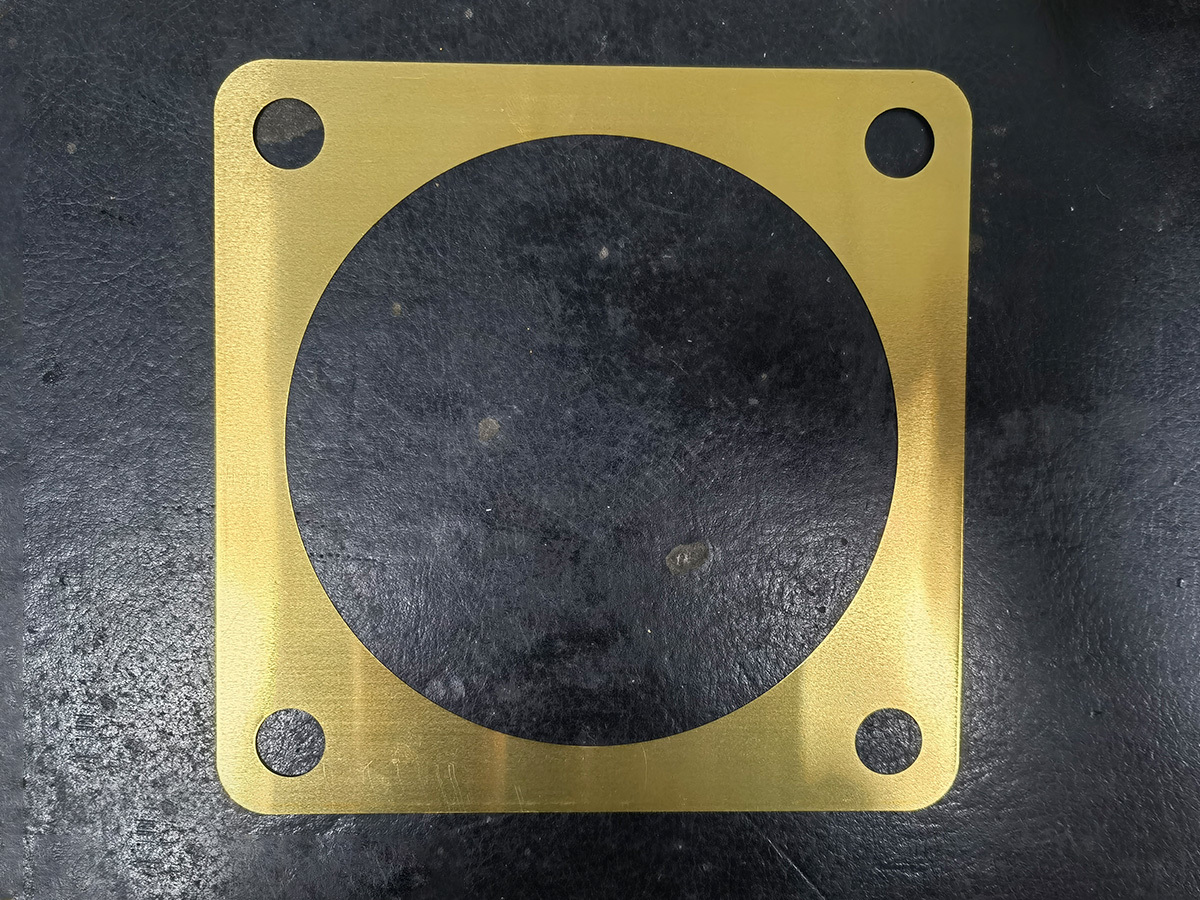

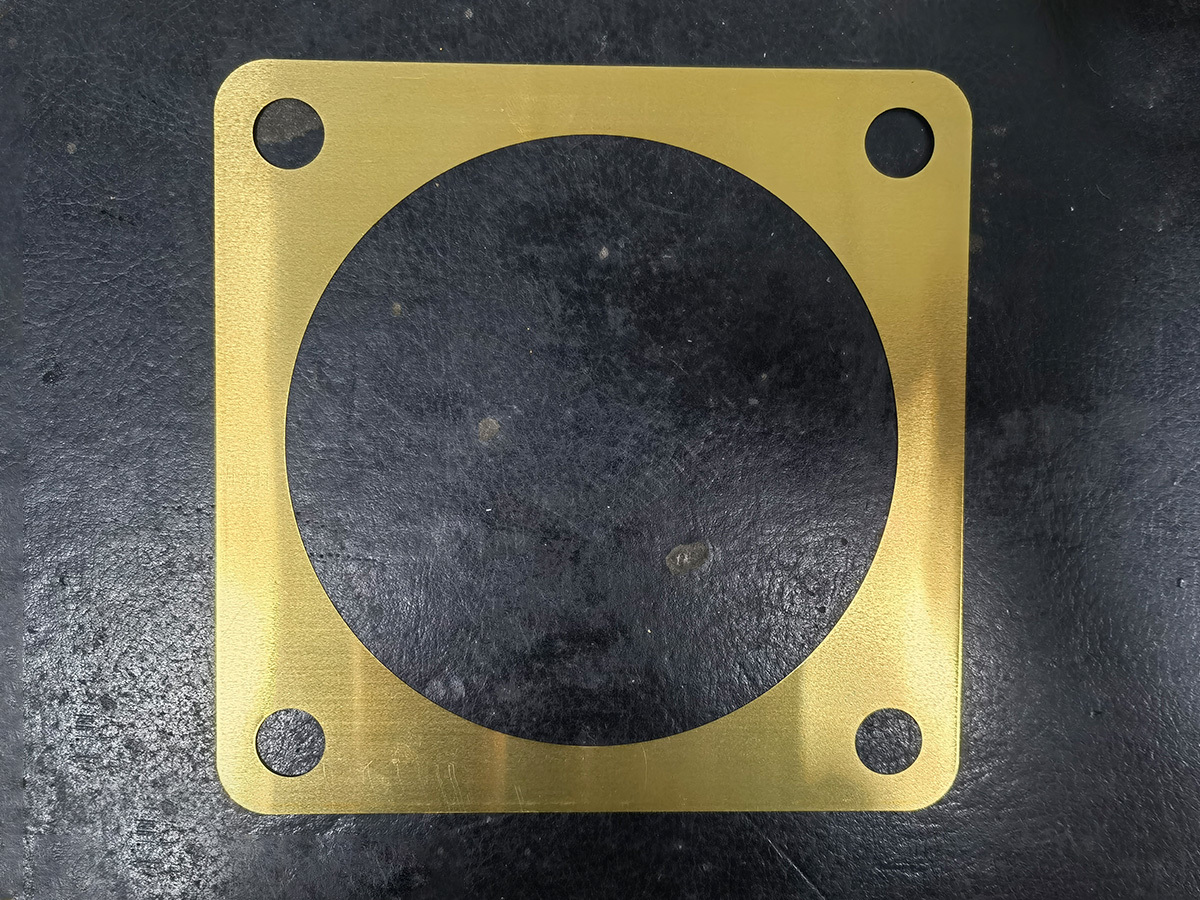

Brass Layered Tear-Off Gasket / Customizable / Direct Factory Supply / Quality Assurance The brass layered tear-off gasket is a metal sealing gasket designed for high-pressure and corrosion-resistant applications, commonly used in industrial equipment requiring sealing, pressure resistance, and corrosion protection. As a precision metal manufacturer, we provide customized brass layered tear-off gaskets with high processing accuracy and stable quality, suitable for various industrial applications. Material Standard: The brass used in our gaskets meets international standards (such as ASTM B16) and features excellent corrosion resistance and oxidation protection. Surface Treatment: The surface of the brass gaskets undergoes coating treatments to enhance wear resistance and corrosion resistance, ensuring long-term performance in harsh environments. Dimensional Tolerances: We strictly control dimensional tolerances according to ISO 2768 standards to ensure consistency and stability in each batch of products. Surface Finish: We ensure that the gasket surface is smooth and free from burrs, cracks, or defects, meeting the quality standards of the hardware industry.

Category:

Key Words:

Table Parameter

| Product Name | Tear-Off Gasket / Gasket |

| Mold Fee | Typically $30 - $140. Design updates are quick, and mold creation can be completed within a day at a low cost. |

| Material | Brass (CuZn) |

| Strength | ≥220 MPa |

| Elongation | ≥30% |

| Hardness | 50-80 HB |

| Tensile Strength | ≥200 MPa |

| Thickness Tolerance | ±0.05mm |

| Shape | Customizable to almost any shape. |

| Temperature Range | -40°C to +200°C |

| Packaging | [Details to be provided] |

| MOQ | [Details to be provided] |

| Delivery Time | Typically 5-15 days for batch production, with expedited production available upon request. |

| Price | Pricing is based on multiple factors, including material, processing methods, and order volume. |

Application Description

Brass layered tear-off gaskets are widely used in:

Automotive engine and transmission sealing

Turbocharger sealing

Industrial pump and valve sealing

Aerospace sealing components

High-pressure sealing in chemical equipment

Factory Description:We have specialized etching production equipment capable of mass-producing tear-off gaskets, with a daily output of up to 500 sheets, equating to approximately 10,000 pieces per day.

Our brass layered tear-off gaskets are made using advanced etching technology, allowing precise control over hole size and shape. With high-precision laser cutting or stamping, we ensure the fine quality of each gasket. Chemical processing not only guarantees the precision of components but also minimizes material waste. Every gasket undergoes strict quality inspection to meet international standards.

Questions and Answers

1. What is the difference between brass layered tear-off gaskets and aluminum layered tear-off gaskets? Material: Brass layered tear-off gaskets are made from brass, offering superior corrosion resistance, high-temperature endurance, and strength, suitable for applications requiring high mechanical performance and durability. Aluminum layered tear-off gaskets are made from aluminum alloy, which is lighter but has lower strength and heat resistance.

|

2. What is the maximum working temperature for brass layered tear-off gaskets? The maximum working temperature for brass layered tear-off gaskets is up to 200°C. However, for high-temperature applications, special surface treatments are recommended to enhance heat resistance. |

3. Can you provide customized sizes and shapes for brass layered tear-off gaskets? Yes, we support custom processing according to client requirements, with precision down to micron levels, meeting various industrial application needs. |

4. How resistant to corrosion are brass layered tear-off gaskets? Brass inherently has good corrosion resistance, particularly in wet and chemical environments. Additionally, we apply coating treatments to the surface of the gaskets to further enhance corrosion resistance. |

5. What surface treatments do you offer? We offer various surface treatments, including nickel plating, gold plating, and oxidation, to enhance corrosion resistance and wear resistance, based on customer requirements. |

6. What is the delivery time? For batch production, the processing time is generally 5-15 days, depending on quantity. If the delivery deadline is tight, please discuss with us in advance for expedited processing. |

| 7. What are your payment terms? As this is a custom product, full payment is required in advance. We support various payment methods, including: Letter of Credit (L/C) Bank Transfer (T/T) PayPal (for small orders) Western Union (for some countries) Alipay/WeChat Pay (for some countries) We can accommodate the payment method that best suits your needs. |

| 8. What happens if the products are defective? Before mass production, we will send you samples for approval. Once you confirm the samples, we will proceed with production. If any products are found defective, please contact us with the specifics, and if the issue is due to our fault, we will replace the products free of charge. |

Factory Description

We have a full set of etching production equipment and mature processing technology. We can manufacture products in any shape with mesh sizes as small as 0.1mm, according to your requirements.

Our Advantage

Factory Direct Shipping

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Experienced Design and Manufacturing Team

We work closely with customers from the design phase to help avoid potential product flaws, ensuring both the functionality and design meet expectations.

Excellent Supply Chain Management

We can quickly adjust production schedules to meet your urgent deadlines, whether it's for large bulk orders or smaller rush orders.

OEM & ODM Support

We offer the option to print your logo or other customizations.

Strict Quality Control

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Certificate

Related Products