Shower Head Spray Plate/Customizable Products/Factory Direct/Precision Mesh

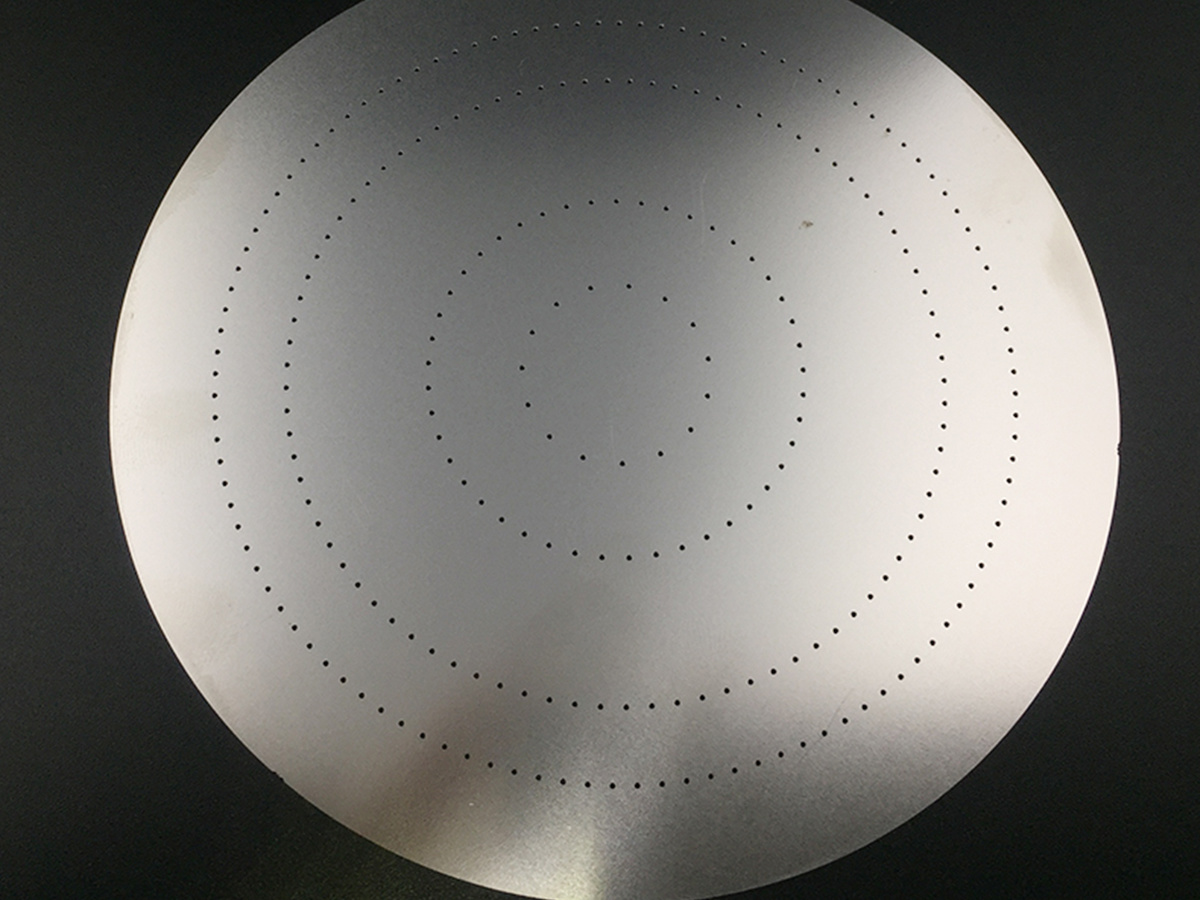

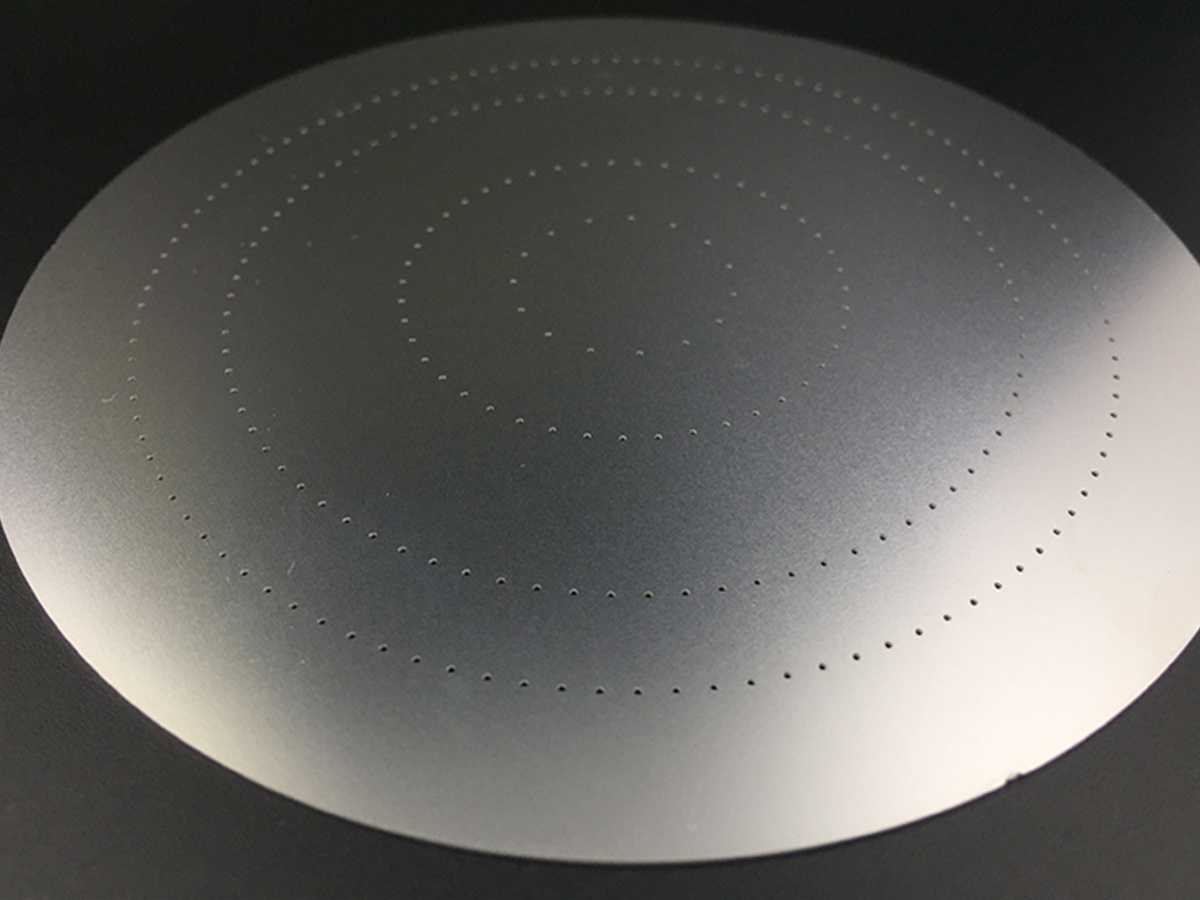

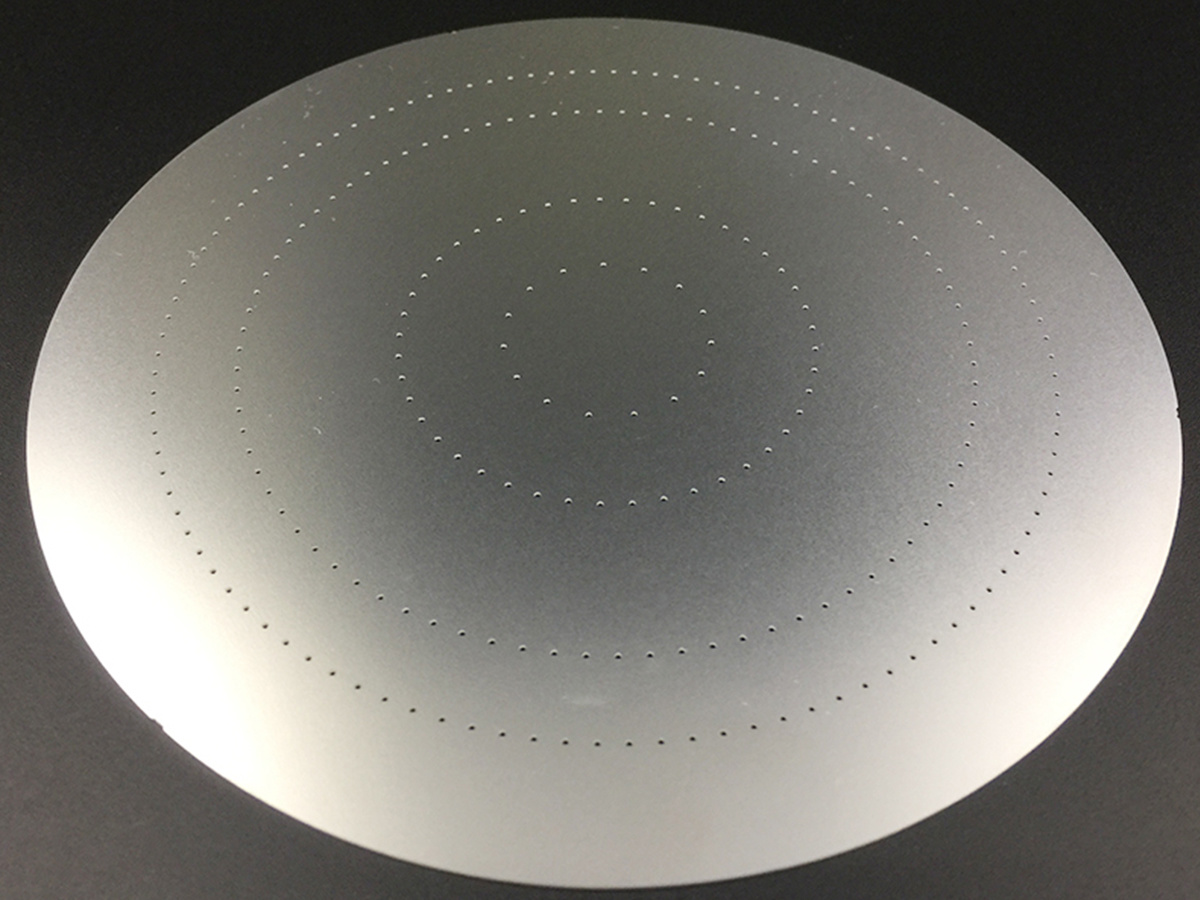

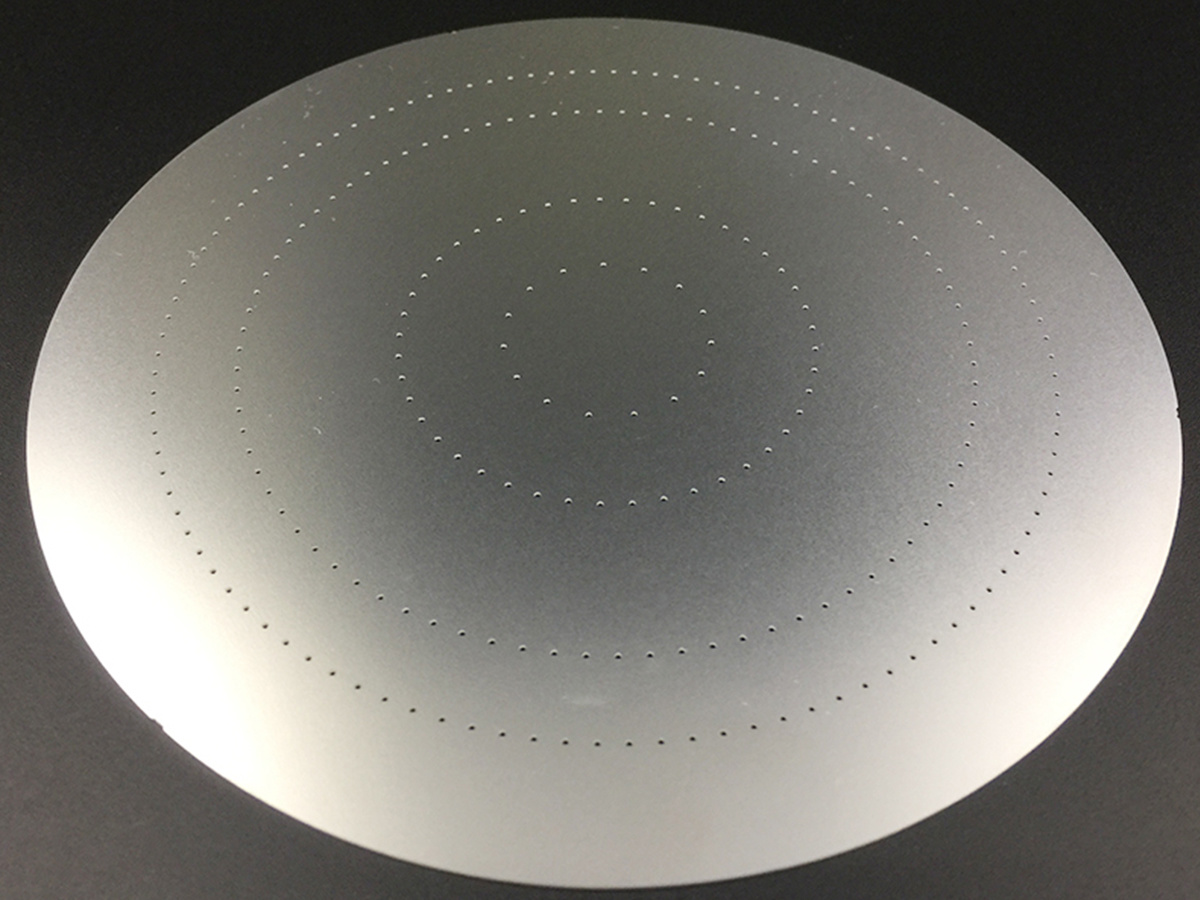

Shower Head Spray Plate / Precision Etching / Manufacturer Direct Supply / Customization Available We use etching technology to manufacture stainless steel shower head spray plates. The process involves chemically etching stainless steel material to create metal plates with multiple tiny holes. The etching technique allows for the customization of hole diameter, hole pitch, and patterns according to customer requirements. This ensures precise, uniform holes without burrs, cracks, or defects, while maintaining the strength of the material. Material Standards: We use stainless steel materials that comply with international standards (such as 304 or 316 stainless steel), offering excellent corrosion resistance and oxidation resistance, ensuring the product will not rust or deform during long-term use. Hole Precision: The etching process allows for fine control of hole diameters. The typical hole diameter range is from 0.2mm to 1.0mm, with the minimum hole size reaching as small as 0.1mm. Specific diameters can be customized based on customer requirements. Tolerance Control: We adhere to ISO 2768 standards, ensuring that the size and hole position tolerance of each shower head spray plate is within ±0.05mm. Surface Treatment: The surface of the spray plate is smooth, free of burrs, and finished to meet industry standards. We use precise inspection tools to ensure surface quality, enhancing durability and appearance.

Category:

Key Words:

Table Parameter

| Product Name | Shower Head Spray Plate |

| Mold Cost | Typically between $30-$140, specific pricing will be discussed based on your requirements. |

| Material | Generally 304 Stainless Steel / 316 Stainless Steel (can be customized upon request) |

| Hole Diameter Precision | As small as 0.1mm |

| Material Thickness | Typically 0.1mm–2.0mm |

| Thickness Tolerance | ±0.05mm |

| Strength | ≥220 MPa |

| Elongation | ≥30% |

| Hardness | 50-80 HB |

| Tensile Strength | ≥200 MPa |

| Hole Pitch Control | ±0.05mm |

| Hole Shape & Layout | Typically round holes with uniform spacing, customizable according to your design |

| Surface Finish | Sandblasting / Brushed / Mirror / Electroplating / PVD Coating |

| Temperature Range | -40°C to +200°C |

| Open Area | 15%~80% |

| Packaging | Customized per order |

| MOQ | Based on customer requirements |

| Lead Time | Mass production typically takes 5-15 days, expedited orders can be arranged |

| Price | Price is determined by material, process, and order quantity |

Application Description

The stainless steel shower head spray plate is a precision metal component used in shower heads to regulate water flow distribution, providing a comfortable and even water spray effect. As a precision metal processing manufacturer, we utilize advanced etching technology to produce high-precision, corrosion-resistant, and wear-resistant shower head spray plates, widely used in residential and hotel shower equipment.

Questions and Answers

| 1.Why use etching technology for shower spray plates? Etching offers high precision, no thermal deformation, and the ability to create complex and tiny holes. This method allows us to precisely control each hole’s size and location, ensuring even water flow without affecting the spray performance. Compared to other methods, etching reduces material waste and improves production efficiency. |

2.How do you ensure the stainless steel spray plate is not deformed or damaged during shipping? 3.For export orders, additional moisture-proof film and fumigated wooden boxes are used to comply with international shipping standards. |

| 3.Is there a minimum order quantity (MOQ) for custom designs or special sizes? 1.Standard Orders: MOQ is 500 pieces (same specifications). 2.Special Customization: For complex patterns or ultra-thin/thick sheets (like 0.1mm or 2.0mm), MOQ can be negotiated to 100-300 pieces. 3.Sampling Service: Supports 1-5 small-batch samples before bulk production. |

| 4.How do you control the product's dimensional tolerance? We use high-precision measurement tools, such as a Coordinate Measuring Machine (CMM), to strictly inspect each batch and ensure dimensional tolerance is within ±0.1mm, meeting customer requirements. |

| 5.Do you provide quality certifications or after-sales support? 1.Certification: We can provide material testing reports (SGS), salt spray testing reports, and RoHS environmental certification. 2.Quality Commitment: Products undergo full inspection before shipping. A one-year warranty is provided, and we offer free replacement for defective products in subsequent orders. If defects occur due to process issues, we support unconditional rework or replacement. |

| 6.Do you require design files? What formats are supported? File Requirements: CAD drawings (.dwg/.dxf) or vector files (.ai/.eps) with key parameters like hole diameter, hole pitch, and outline dimensions. Design Assistance: If no design files are available, we can reverse-engineer from samples or provide free layout solutions based on customer requirements. |

| 7.Do you support custom hole diameters and pitches? Yes, we support customizing hole diameters and pitches based on customer requirements to meet different shower head design specifications. |

| 8.How do you ensure the corrosion resistance of stainless steel spray plates? We use high-quality 304 or 316 stainless steel, which is naturally corrosion-resistant and ideal for humid bathroom environments. Additionally, our products undergo precise surface treatments to further enhance their corrosion resistance. |

| 9.What are your payment terms? Since these are custom products, full payment is required upfront. We support various payment methods including: 1.Letter of Credit (L/C) 2.Wire Transfer (T/T) 3.PayPal (for small orders) 4.Western Union (for certain countries) 5.Alipay/WeChat Pay (for some regions) 6.Bank Transfer |

Factory Description

We have a full set of etching production equipment and mature processing technology. We can manufacture products in any shape with mesh sizes as small as 0.1mm, according to your requirements.

Our Advantage

Factory Direct Shipping

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Experienced Design and Manufacturing Team

We work closely with customers from the design phase to help avoid potential product flaws, ensuring both the functionality and design meet expectations.

Excellent Supply Chain Management

We can quickly adjust production schedules to meet your urgent deadlines, whether it's for large bulk orders or smaller rush orders.

OEM & ODM Support

We offer the option to print your logo or other customizations.

Strict Quality Control

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Certificate

Related Products