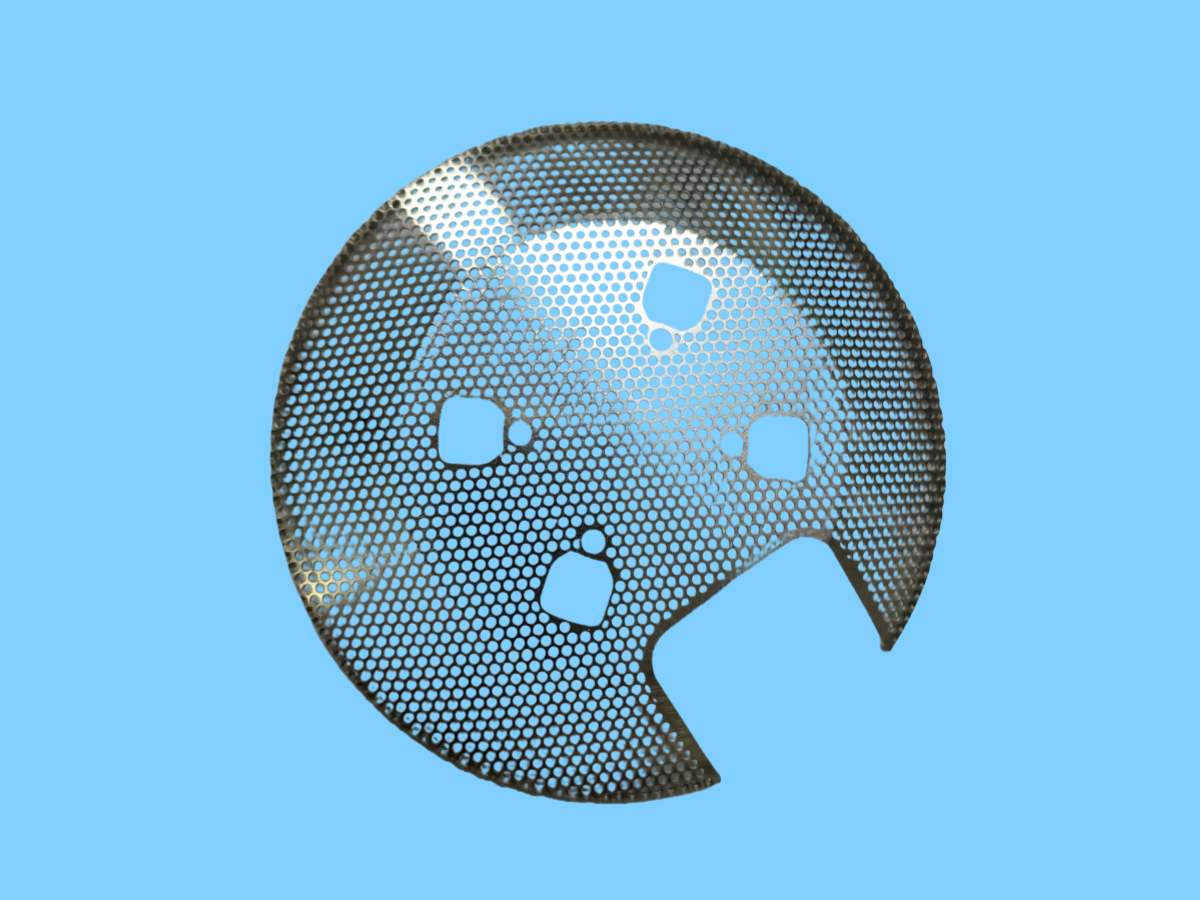

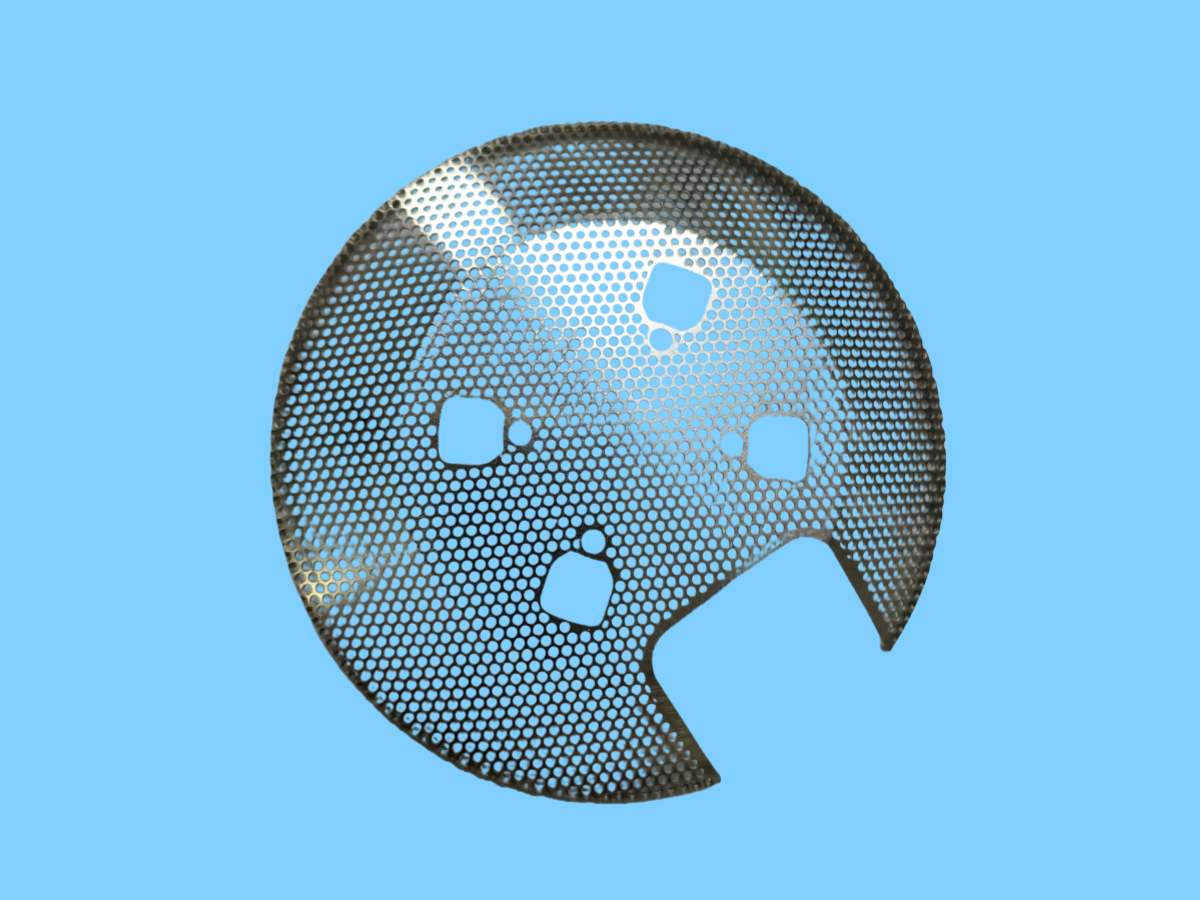

Hair Dryer Rear Inlet Mesh/Customizable Products/Factory Direct/Custom Logo

Speaker Grilles / Precision Etching / Factory Direct / Customizable Customizable in various materials, hole sizes, shapes, and patterns. Widely used in high-end audio equipment, automotive audio systems, musical instrument speakers, smart home devices, and more. The product optimizes acoustic performance, provides dust and protection features, and serves as an aesthetic decoration—making it a key component for enhancing device quality. Material Selection Materials: Stainless Steel (304/316L), Brass, Aluminum Alloy, Nickel Alloy, etc., with thickness ranging from 0.05mm to 2.0mm. Customization: Supports surface treatments such as matte, mirror finish, electroplating, and spray coating. Precision Etching Process Design & Plate Making: High-precision digital film templates are created from customer drawings or requirements to ensure accurate pattern reproduction. Coating & Exposure: The base material is evenly coated with a photosensitive resin, followed by UV exposure to solidify the designed pattern. Chemical Etching: Acidic or alkaline etching solutions are used to precisely etch unexposed areas, forming uniform mesh holes with an accuracy of ±0.02mm. Cleaning & Quality Inspection: Residual chemicals are removed, and 100% inspection is performed to check hole size, spacing, and surface finish. Precision Parameters Minimum Hole Size: 0.1mm (adjustable based on material thickness), supports round holes, square holes, hexagons, and other custom shapes. Tolerance Control: Hole size tolerance ≤ ±5%, hole pitch tolerance ≤ ±0.03mm, conforming to IPC6013 industry standards. Consistency: Etching uniformity across the sheet >98%, with no burrs, warping, or deformation.

Category:

Key Words:

Table Parameter

| Product Name | Speaker Grilles |

| Mold Fee | Typically $30–$140, negotiable based on your requirements. |

| Material | Stainless Steel (304/316L), Brass, Aluminum Alloy, Nickel Alloy, etc. Commonly 304/316 stainless steel for excellent corrosion resistance, oxidation resistance, and mechanical strength. |

| Mesh Hole Size | Can process holes as small as 0.1mm. |

| Material Thickness | Typically 0.1mm–2.0mm. |

| Hole Shape & Layout | Typically round holes, evenly spaced; custom layouts available based on your drawing. |

| Tolerance Range | Tolerance varies by material and thickness; precision is approximately 10% of material thickness. |

| Open Area | 15%–80%. |

| Surface Treatment | Sandblasting, Brushed Finish, Mirror Finish, Electroplating, PVD Coating, and other custom treatments. |

| Size | Customizable per customer drawing (maximum size 1200mm). |

| Packaging | [To be filled in based on actual packaging methods]. |

| Minimum Order Quantity | [To be filled in based on MOQ policy]. |

| Delivery Time | Standard lead time is 5–15 days for batch orders. Expedited production can be arranged if needed. |

| Price | Pricing is based on factors such as material, process, and order quantity. |

Application Description

Home Audio: Smart speakers, Hi-Fi audio systems, home theaters.

Professional Equipment: Stage sound systems, conference systems, recording studio monitors.

Car Audio: Car speaker covers, central control speaker meshes.

Outdoor Audio: Waterproof speakers, public square PA systems.

Questions and Answers

|

Q1: What are the advantages of etching vs traditional methods?

|

|||||||||||||||

| Q2: How do you ensure the stainless steel mesh remains undamaged during shipping? Packaging: Individual products are wrapped in bubble wrap with corner protectors to prevent surface scratches. Bulk orders are secured in custom vacuum trays/wooden boxes to prevent deformation. Export orders include moisture-proof film and fumigated wooden boxes to meet international shipping standards. |

|||||||||||||||

| Q3: Is there a minimum order quantity (MOQ) for custom designs or sizes? Standard Orders: MOQ is 500 pieces (same specification). Special Custom Orders: MOQ can be negotiated for complex patterns or ultra-thin/thick materials (e.g., 0.1mm or 2.0mm), ranging from 100 to 300 pieces. Sample Service: Supports small-batch sampling (1–5 pieces) for confirmation before mass production. |

|||||||||||||||

| Q4: How do you ensure the precision and consistency of the mesh holes? Technical Assurance: Fully automated optical positioning etching equipment ensures tolerance within ±0.02mm. Laser inspections are performed on the first sample before production. Random hole size and open area checks are conducted every 2 hours during mass production. Free samples are provided for customer verification before mass production begins. |

|||||||||||||||

| Q5: Do you support special surface treatments? Yes, we offer electroplating (nickel, gold), sandblasting, anodizing, PVD coating, and options for fingerprint-resistant or antimicrobial properties. Here’s the translation of the provided section, tailored for the hardware industry and business communication: |

|||||||||||||||

| Q6: Do I need to provide design files? What file formats are supported? File Requirements: CAD drawings (.dwg/.dxf) or vector graphics (.ai/.eps) are required, with key parameters such as hole size, hole pitch, and outline dimensions clearly marked. Design Assistance: If no design files are available, we can reverse engineer from samples or provide free layout solutions based on your requirements. |

|||||||||||||||

| Q7: Can the etched speaker grilles meet dustproof and waterproof requirements? A: Yes, through hole design (e.g., micro holes combined with multi-layer structures), we can achieve IP54 to IP67 protection ratings, further enhanced by adding dustproof fabric. |

|||||||||||||||

| Q8: How does the open area affect sound quality? How do I choose the right parameters? Acoustic Recommendations: For Hi-Fi (high-fidelity) sound systems: We recommend an open area of ≥60% to minimize sound wave attenuation. For outdoor dustproof requirements: The open area can be reduced to 30%–40%, balancing sound permeability and blocking foreign objects. |

|||||||||||||||

| Q9: What is the smallest hole size that can be achieved? What shape can the holes take? How can the holes be arranged? For common materials (e.g., stainless steel), the minimum hole size is 0.1mm. The thinner the material, the smaller the achievable hole size (e.g., for 0.05mm thick material, hole sizes can reach 0.08mm). Specific sizes depend on the material characteristics. Custom mesh layouts are available based on your needs, ensuring the dustproof mesh not only blocks dust but also maintains excellent sound transmission across different frequency ranges. |

|||||||||||||||

| Q10: What are your payment terms? Since this is a custom product, full payment in advance is required. We offer a variety of payment methods, including: Letter of Credit (L/C) Telegraphic Transfer (T/T) PayPal (for small orders) Western Union (for certain countries) Alipay/WeChat Pay (for some countries) We can select the most suitable payment method based on your needs. Bank Transfer |

Factory Description

We have a full set of etching production equipment and mature processing technology. We can manufacture products in any shape with mesh sizes as small as 0.1mm, according to your requirements.

Our Advantage

Factory Direct Shipping

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Experienced Design and Manufacturing Team

We work closely with customers from the design phase to help avoid potential product flaws, ensuring both the functionality and design meet expectations.

Excellent Supply Chain Management

We can quickly adjust production schedules to meet your urgent deadlines, whether it's for large bulk orders or smaller rush orders.

OEM & ODM Support

We offer the option to print your logo or other customizations.

Strict Quality Control

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Certificate

Related Products