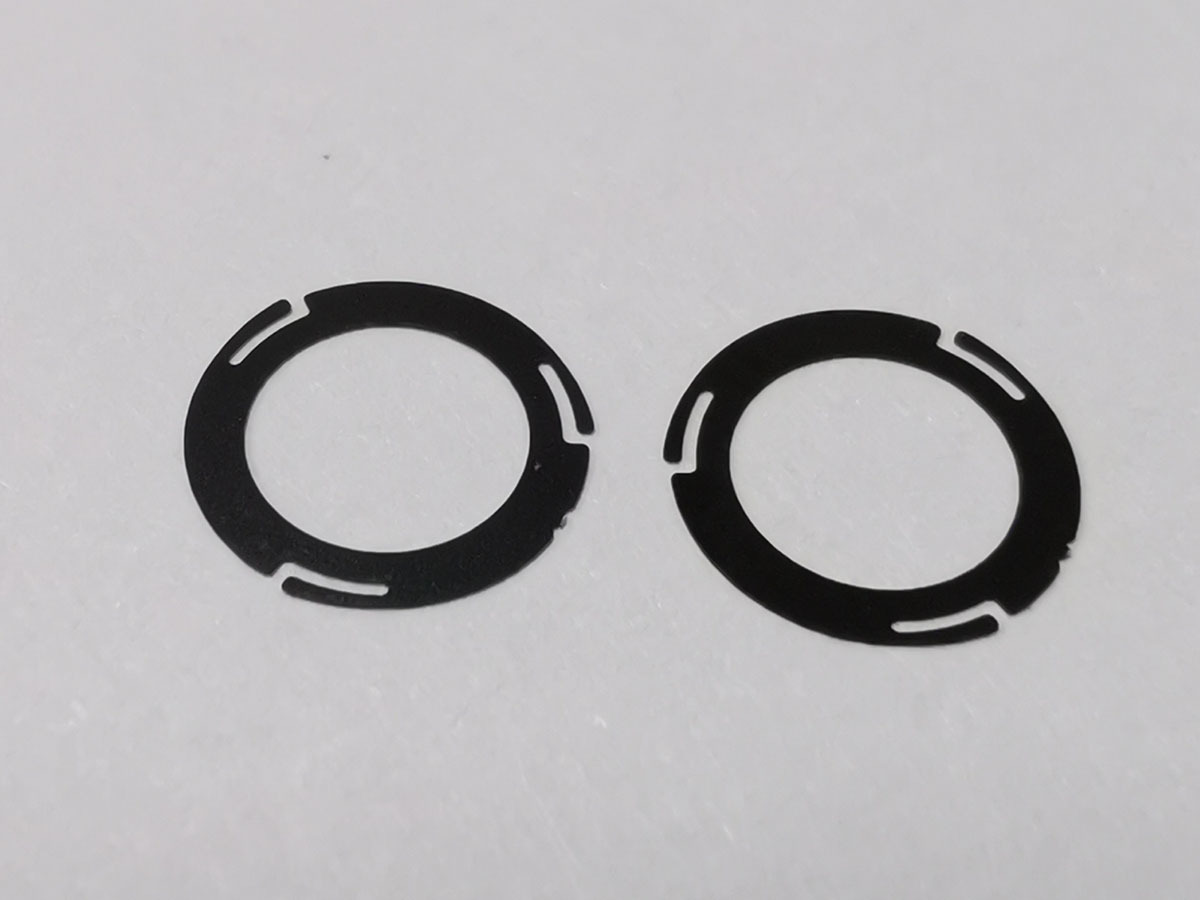

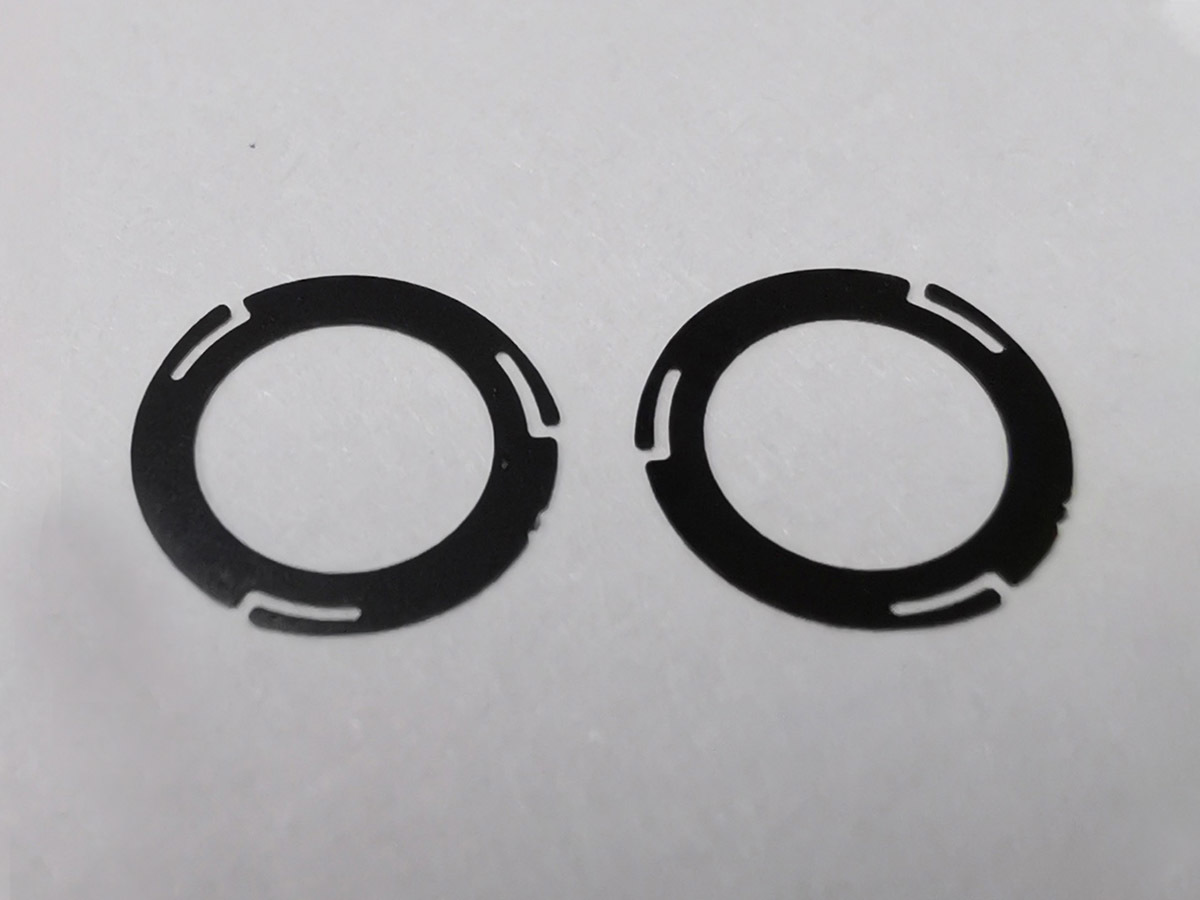

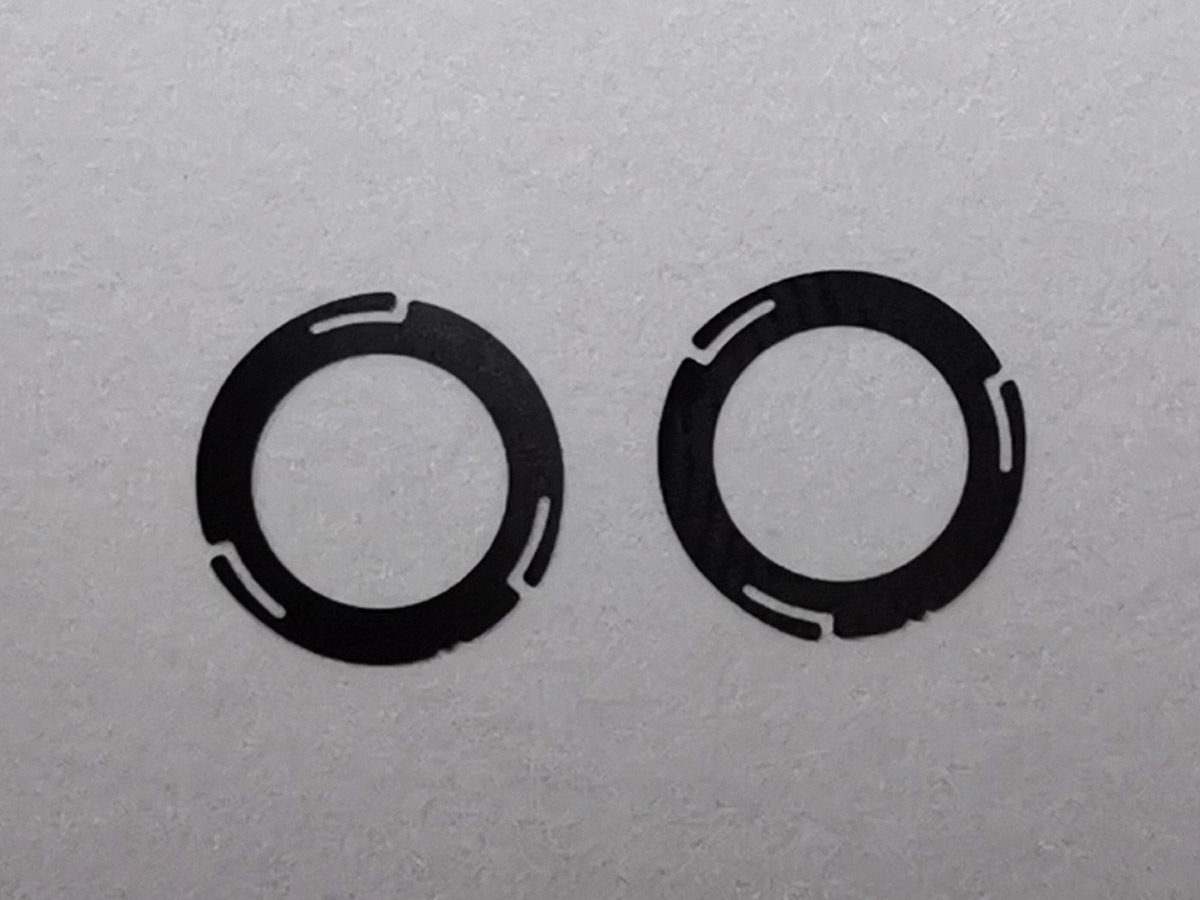

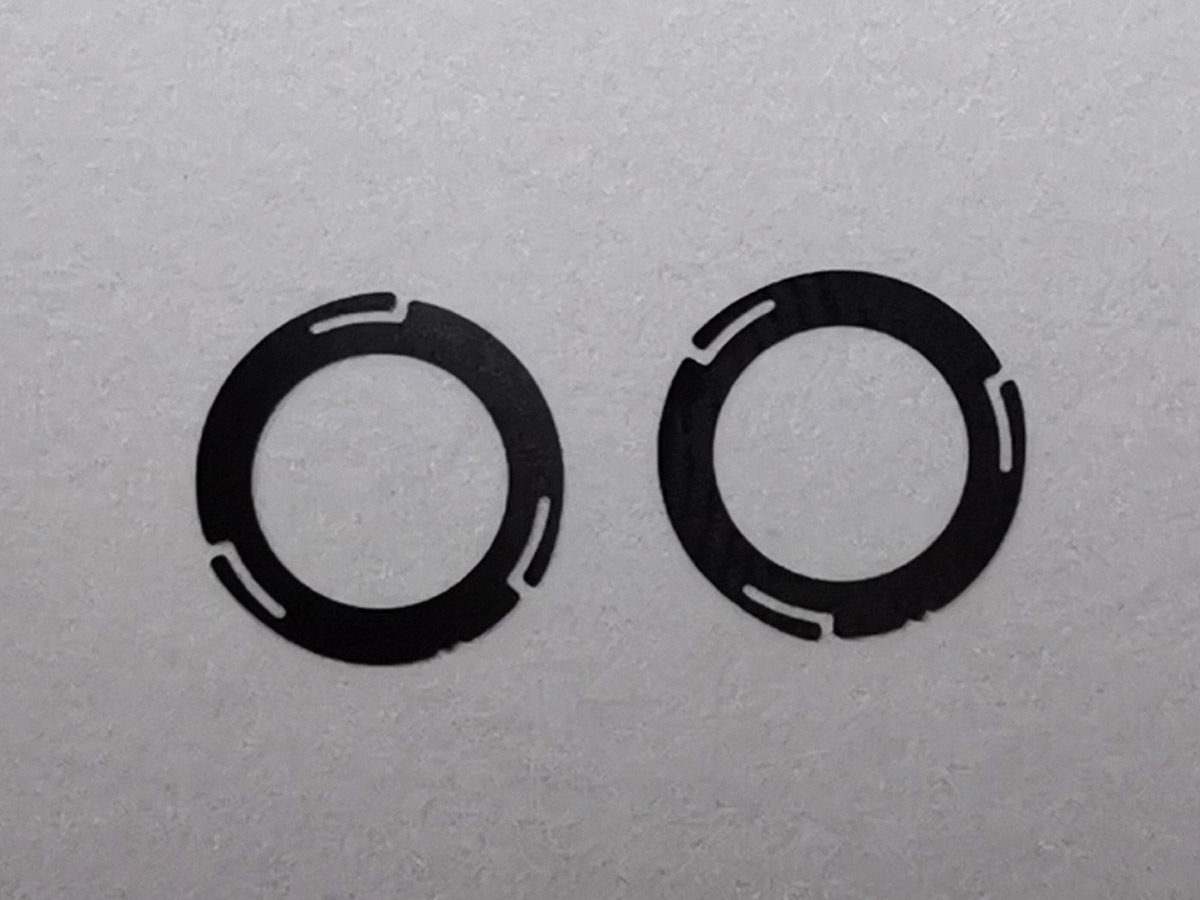

Endoscope Diffraction Grating /Customizable Products/Factory Direct/Precision Size Control

Endoscope Grating / Customizable / Precision Etching by Source Factory / Single or Bulk Orders Supported Endoscope gratings are produced using precision etching technology, primarily used for optical transmission in endoscope systems. We offer customization services and can manufacture gratings in various sizes, shapes, and specifications based on customer requirements, ensuring high precision, excellent stability, and outstanding optical performance. The product is made from 304 or 316 stainless steel, offering excellent corrosion resistance, high temperature resistance, and good mechanical strength, making it suitable for long-term use in medical environments.

Key Words:

Table Parameter

| Product Name | Stainless Steel Etched Endoscope Grating |

| Material | 304 Stainless Steel / 316 Stainless Steel |

| Hole Diameter | 0.1mm - 5mm |

| Hole Shape | Circular or Customized Shapes |

| Aperture Ratio | Typically 30% - 70%, adjustable based on application |

| Material Thickness | 0.1mm - 1mm (Common thicknesses: 0.2mm, 0.3mm, 0.5mm) |

| Thickness Tolerance | ±0.05mm |

| Tensile Strength | ≥600MPa |

| Elongation | ≥30% |

| Hardness | 50-80 HB |

| Tensile Strength | ≥520MPa |

| Hole Pitch | Adjustable from 0.1mm to 1mm, common sizes 0.2mm, 0.5mm |

| Surface Finish | Ra ≤ 0.8 µm |

| Temperature Range | -40°C to +200°C |

| Surface Treatment | Sandblasting, Brushed, Polished, Electroplating, PVD Coloring |

| Dimensions | Custom sizes based on customer drawings, max size 1200mm |

| Delivery Time | Bulk production cycle: 5-15 days (depending on quantity) |

Application Description

Etched endoscope gratings are widely used in the following fields:

Medical Devices: Used in endoscope systems for precise optical transmission, ensuring high image quality.

Optical Instruments: Used in high-precision optical measurement devices to ensure accurate light wave transmission.

Scientific and Experimental Equipment: Provide precise grating structures in scientific equipment, commonly used in lasers, optical sensors, and more.

Questions and Answers

1.Why choose etching technology for endoscope gratings? Etching offers extremely high precision and can process micron-level holes, ensuring high precision and excellent optical performance. Unlike traditional methods, etching avoids thermal deformation, maintaining stable optical performance. |

2.Can the hole diameter and pitch be customized? Yes, we can customize the hole diameter, pitch, and aperture shape according to your requirements. The common hole diameter range is from 0.1mm to 5mm, and the pitch can be adjusted as needed. |

3.Do you support bulk production? Our production line supports bulk production and ensures consistency and high precision in every batch. Whether it's small-batch customization or large-scale orders, we deliver on time. |

4.Can you provide samples? Yes, we can provide samples for testing based on your requirements. Once the samples are approved, we can proceed with bulk production. |

5.What is the delivery time? For bulk production, the processing time is generally 5-15 days, depending on the quantity. In special cases, if the delivery time is very tight, we can discuss adjustments. |

6.What are your payment methods? As this is a customized product, full payment in advance is required. We support various payment methods including: |

7.How do you handle defective products? We will send you samples for confirmation before formal production. If the product is defective due to our fault, we will replace it for free on your next order. |

Factory Description

We have a full set of etching production equipment and mature processing technology. We can manufacture products in any shape with mesh sizes as small as 0.1mm, according to your requirements.

Our Advantage

Factory Direct Shipping

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Experienced Design and Manufacturing Team

We work closely with customers from the design phase to help avoid potential product flaws, ensuring both the functionality and design meet expectations.

Excellent Supply Chain Management

We can quickly adjust production schedules to meet your urgent deadlines, whether it's for large bulk orders or smaller rush orders.

OEM & ODM Support

We offer the option to print your logo or other customizations.

Strict Quality Control

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Certificate

Related Products