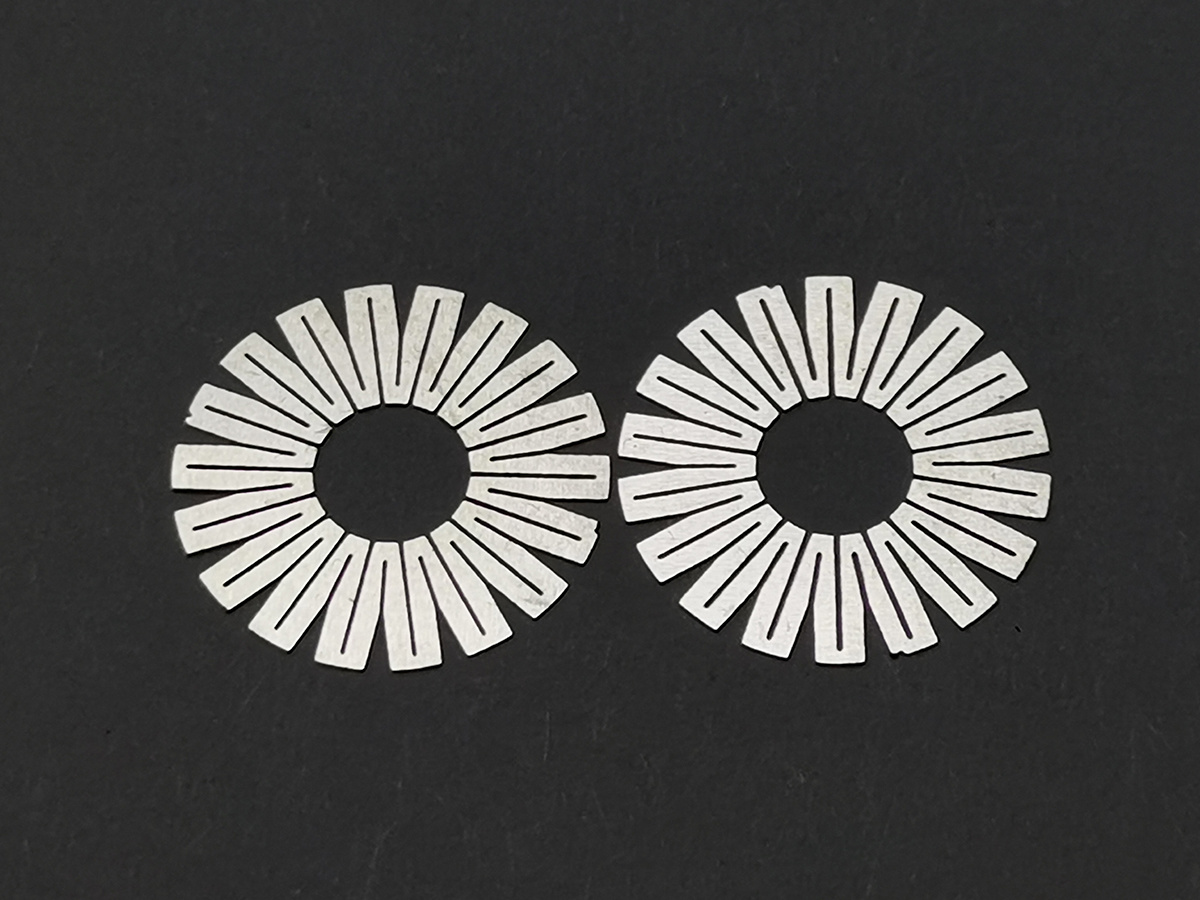

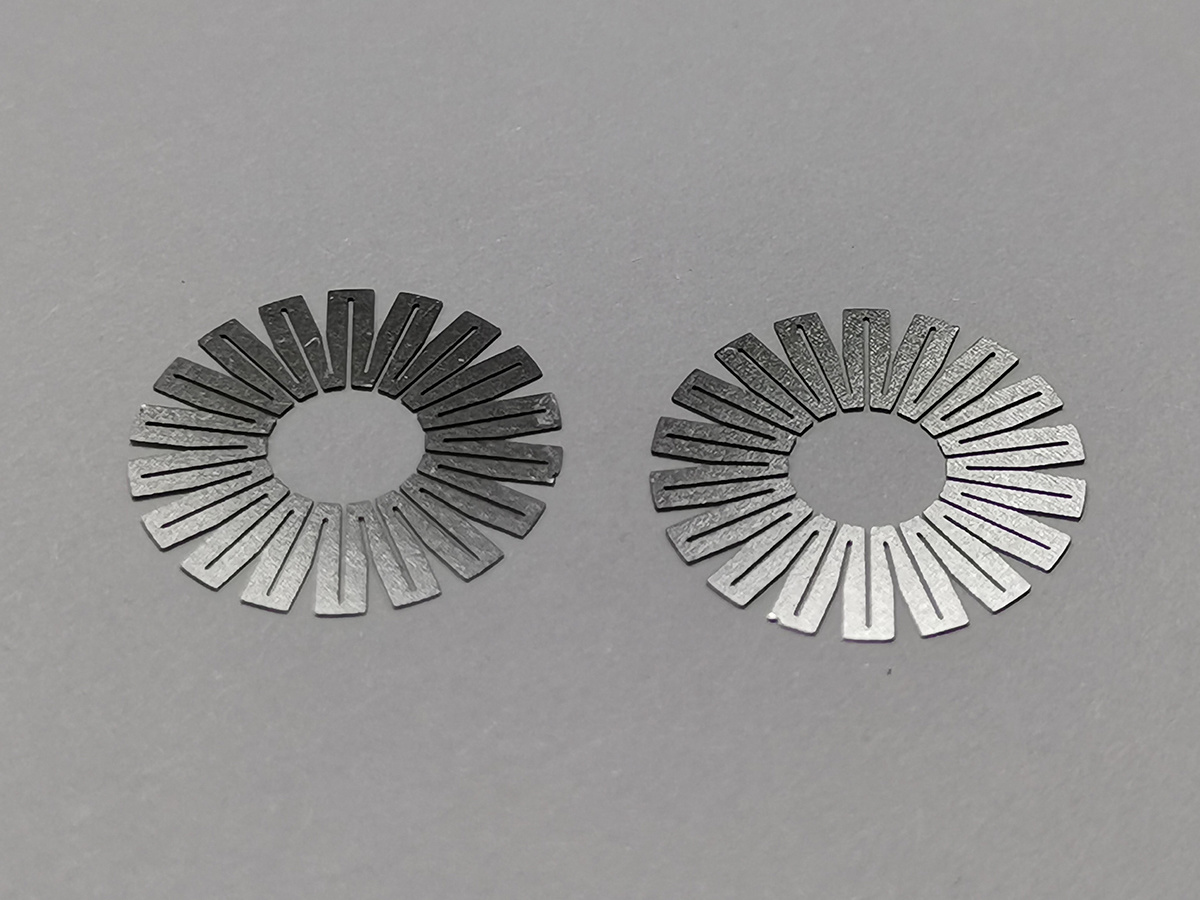

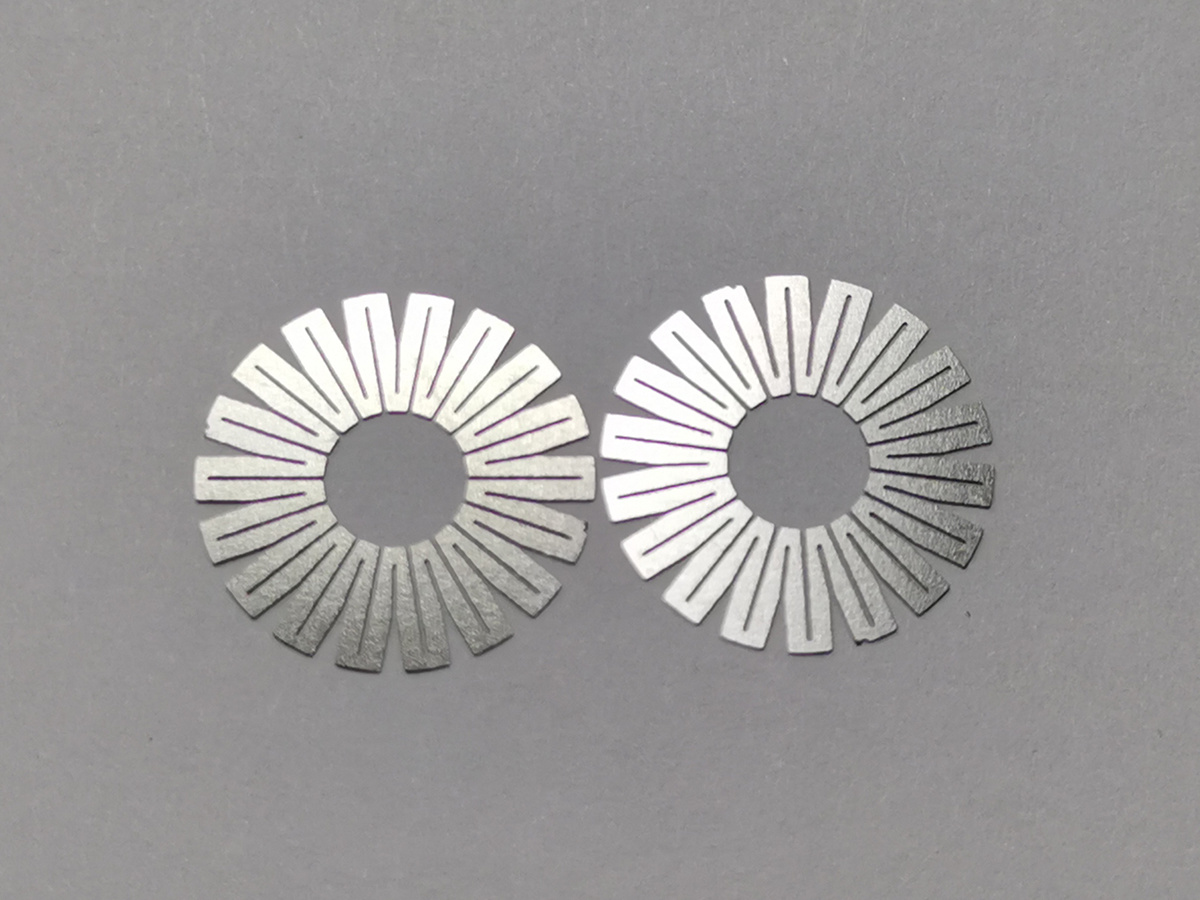

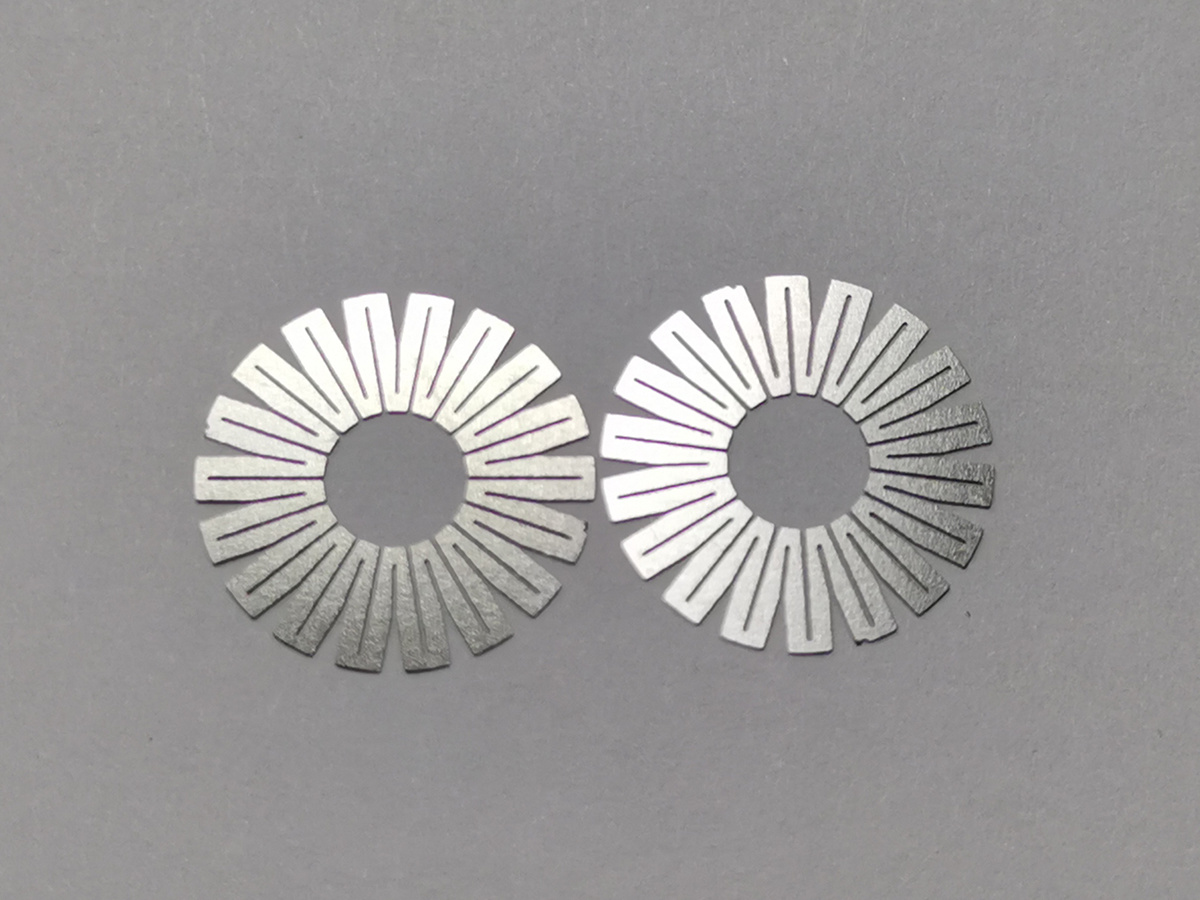

Metal Etched Spring Contacts / Etched Contact Discs / Precision Spring Contacts / Etched Spring Contact Sheets

Metal Spring Contacts / Precision Etching / Custom Manufacturing / Factory Direct Shipping We employ advanced etching technology to provide customers with high-precision and durable spring contact products. Metal etching spring contacts are widely used in industries such as electronic components, automotive, home appliances, and more. They are especially suitable for applications requiring high precision, strength, and durability. Our products are customizable to meet different sizes, shapes, thicknesses, and hole rates, ensuring high quality. Material: Stainless Steel: Suitable for high-temperature and corrosive environments, and applications requiring high elasticity and durability. Copper Alloy: Provides excellent electrical conductivity, ideal for electronic components and high-frequency current applications. Brass: Offers good machinability and elasticity, commonly used in precision contact parts. Aluminum Alloy: Lightweight with high strength, suitable for applications requiring lightweight and high conductivity. Manufacturing Process: Metal etching spring contacts are produced using a precision etching process. This process uses chemical etching to remove unnecessary metal and finely retain the desired shapes and apertures. The process offers the following advantages: High Precision: Capable of processing micron-level details to ensure that the size, aperture, shape, and hole accuracy of the spring contacts meet design specifications. No Thermal Deformation: Avoids thermal deformation seen in traditional machining, ensuring product consistency and stability. Mass Production: Suitable for large-volume production, ensuring stable quality across batches. Burr Control: Advanced burr removal processes ensure smooth edges without burrs. Accuracy Control: Aperture and pitch deviations can be controlled within ±0.1mm, ensuring precise hole effects.

Category:

Key Words:

Table Parameter

| Name | Metal Etched Spring Contacts / Etched Contact Discs / Precision Spring Contacts / Etched Spring Contact Sheets |

| Material | Stainless Steel, Copper Alloy, Brass, Aluminum Alloy |

| Hole Size | 0.1mm - 5mm |

| Shape & Size | Customizable shapes (round, rectangular, custom, etc.), size ranges from micron-level to millimeter-level |

| Resistivity | Varies by material |

| Hole Rate | 30% - 80% (customized based on client needs) |

| Material Thickness | 0.05mm - 2mm |

| Error Control | ±0.05mm (thickness), ±0.1mm (hole size, pitch) |

| Tensile Strength | ≥600MPa |

| Hardness | 50-80 HB |

| Temperature Range | -40°C to +1000°C |

| Surface Treatment | Sandblasting, brushing, electroplating, etc. |

| Delivery Time | 7-15 days (depending on order quantity) |

Application Description

Metal etching spring contacts are widely used in the following industries:

Electronics: Used in manufacturing precision electronic components, contact parts, etc.

Automotive: Used in automotive sensors, contact points, battery connections, and other precision parts.

Home Appliances: Used in appliances requiring elastic contact parts, switches, and sensors.

Telecommunications: Used in precision contact parts for telecommunications devices.

Other Industries: Also widely used in aerospace, medical devices, instrumentation, etc.

Questions and Answers

1. Why choose etching technology? Etching technology provides high precision and micron-level processing capabilities, allowing for the precise replication of complex details, avoiding thermal deformation seen in traditional machining, and ensuring product consistency and stability. |

2. Can the size and shape of etching spring contacts be customized? Yes, we offer customization services, supporting the production of different sizes and shapes based on customer requirements. |

3. How is thickness and error control handled? Thickness ranges from 0.05mm to 2mm, with error control at ±0.05mm (thickness) and ±0.1mm (hole size, pitch). |

4. How are samples charged? Most of our products can be sampled for free. Samples or similar products are available, while custom or high-cost samples are subject to sample fees. Bulk orders are priced per unit. |

5. What is the delivery time? For large quantities, mass production typically takes 5-15 days. In special cases where a product's delivery deadline is urgent, we can negotiate an expedited schedule. |

6. What are your payment terms? As custom products, full prepayment is required. We accept multiple payment methods, including: |

7. How do you handle defective products? Before full production, we will send you samples for confirmation. Once you approve the samples, we will begin mass production. If any product defects arise, you can contact us, and if the issue is due to our fault, we will replace the defective products at no extra charge. |

Factory Description

We have a full set of etching production equipment and mature processing technology. We can manufacture products in any shape with mesh sizes as small as 0.1mm, according to your requirements.

Our Advantage

Factory Direct Shipping

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Experienced Design and Manufacturing Team

We work closely with customers from the design phase to help avoid potential product flaws, ensuring both the functionality and design meet expectations.

Excellent Supply Chain Management

We can quickly adjust production schedules to meet your urgent deadlines, whether it's for large bulk orders or smaller rush orders.

OEM & ODM Support

We offer the option to print your logo or other customizations.

Strict Quality Control

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Certificate

Related Products