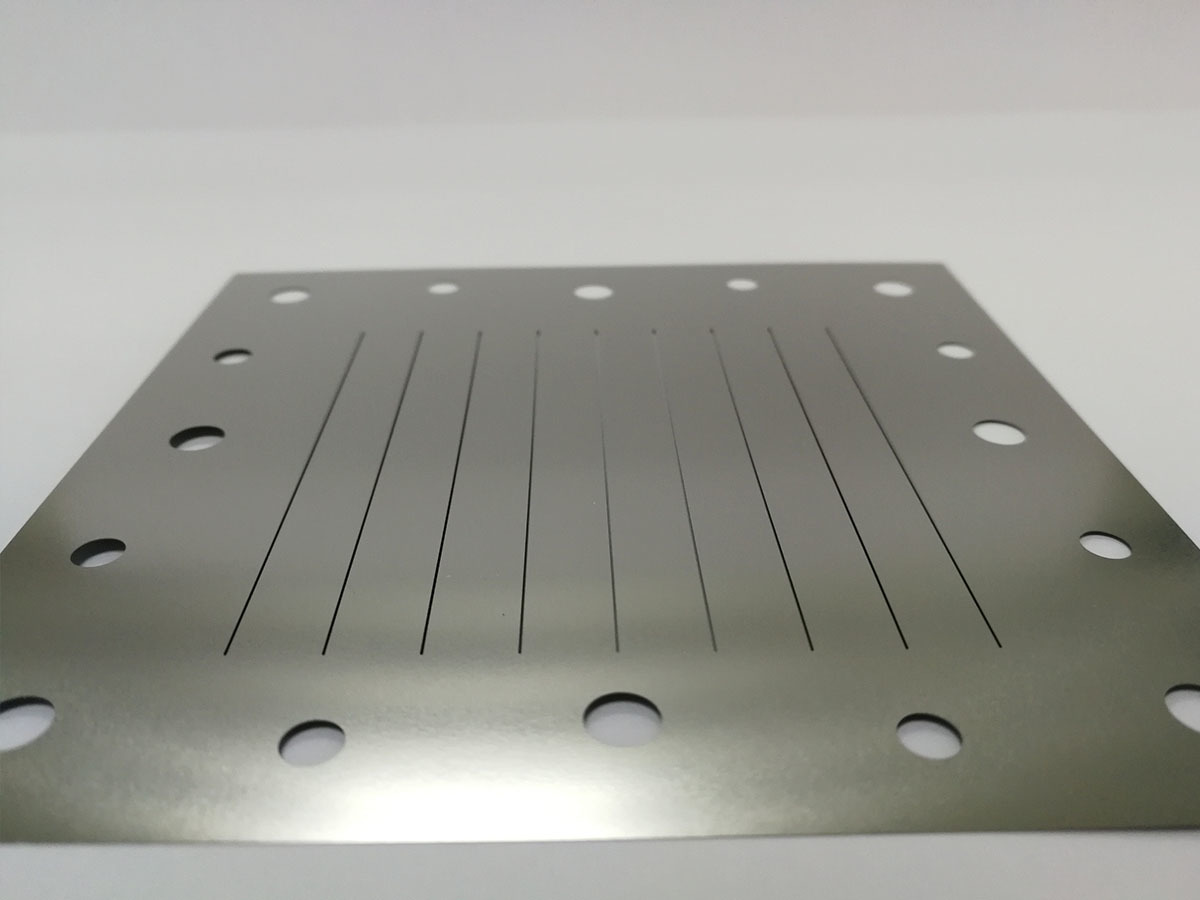

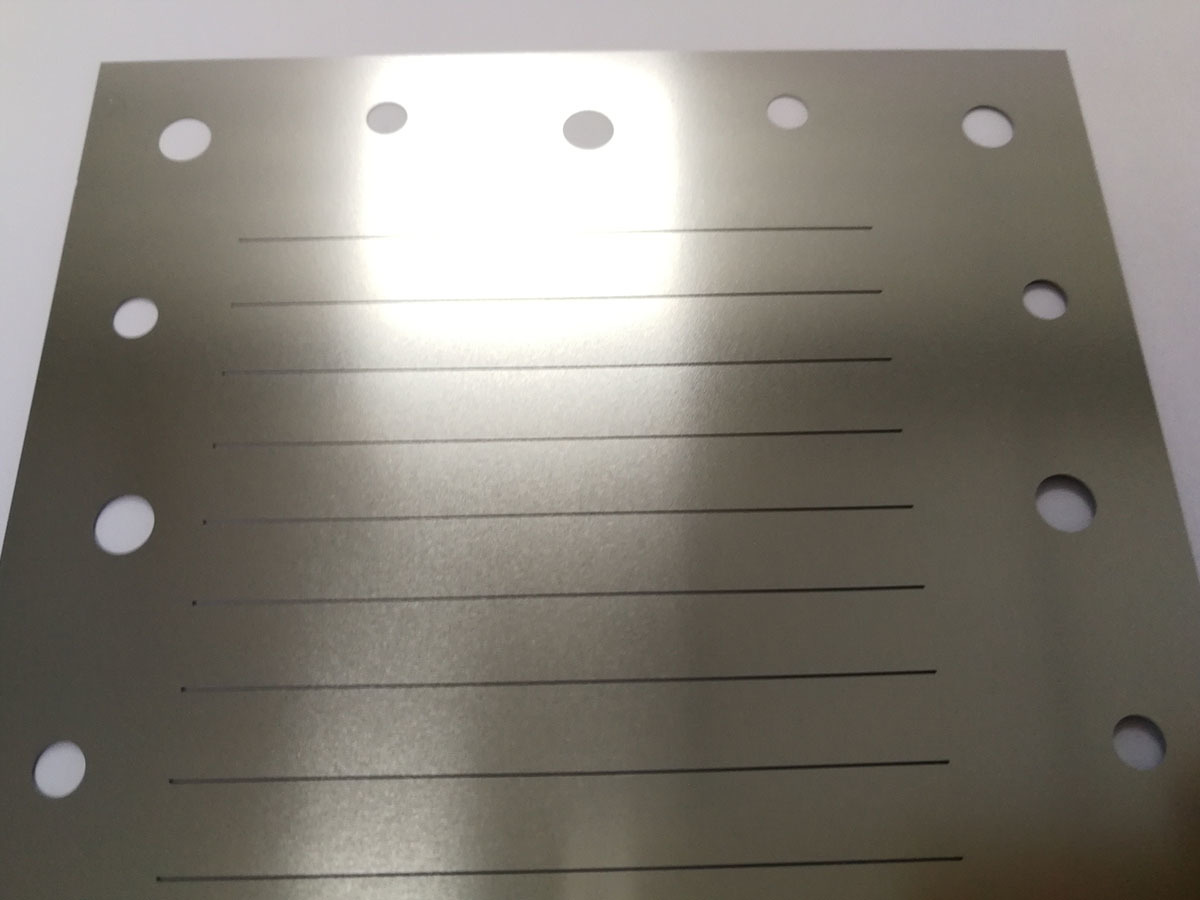

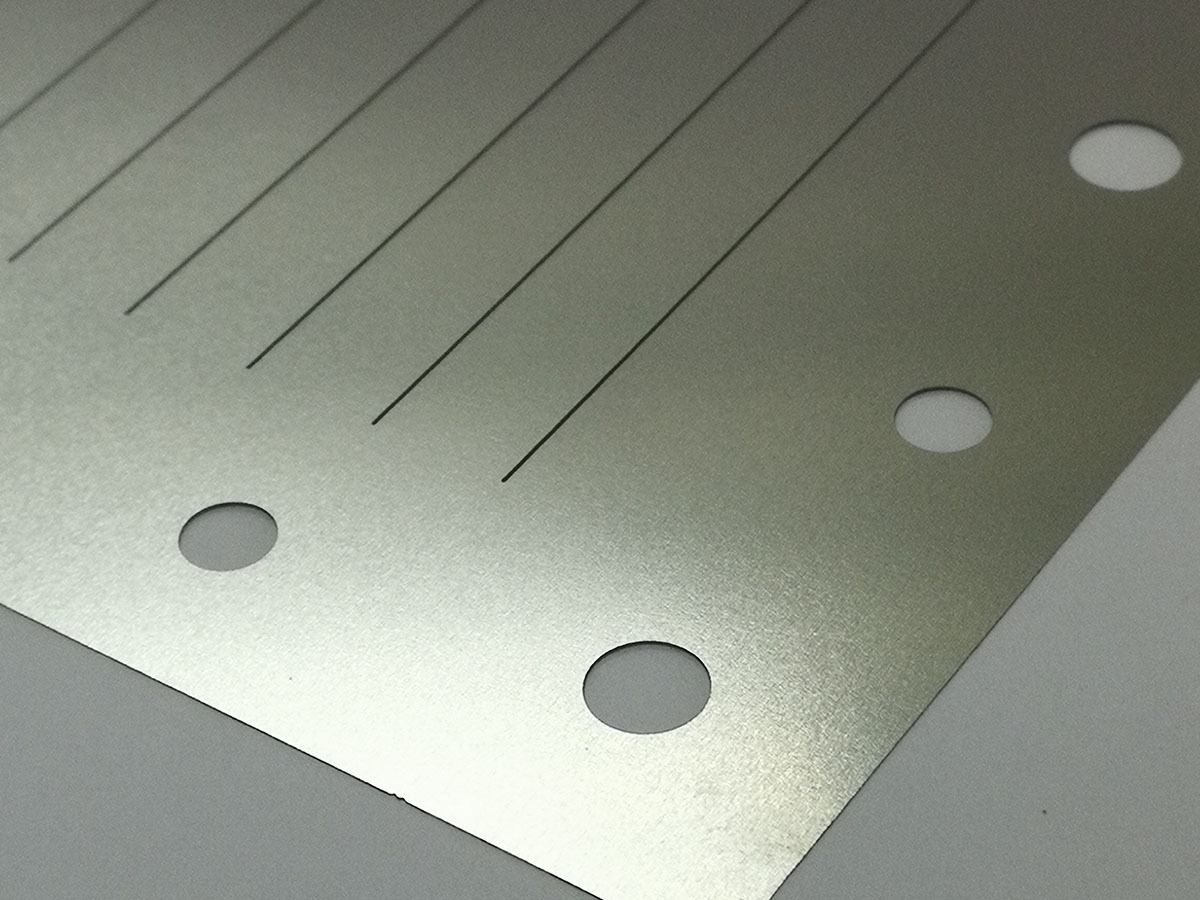

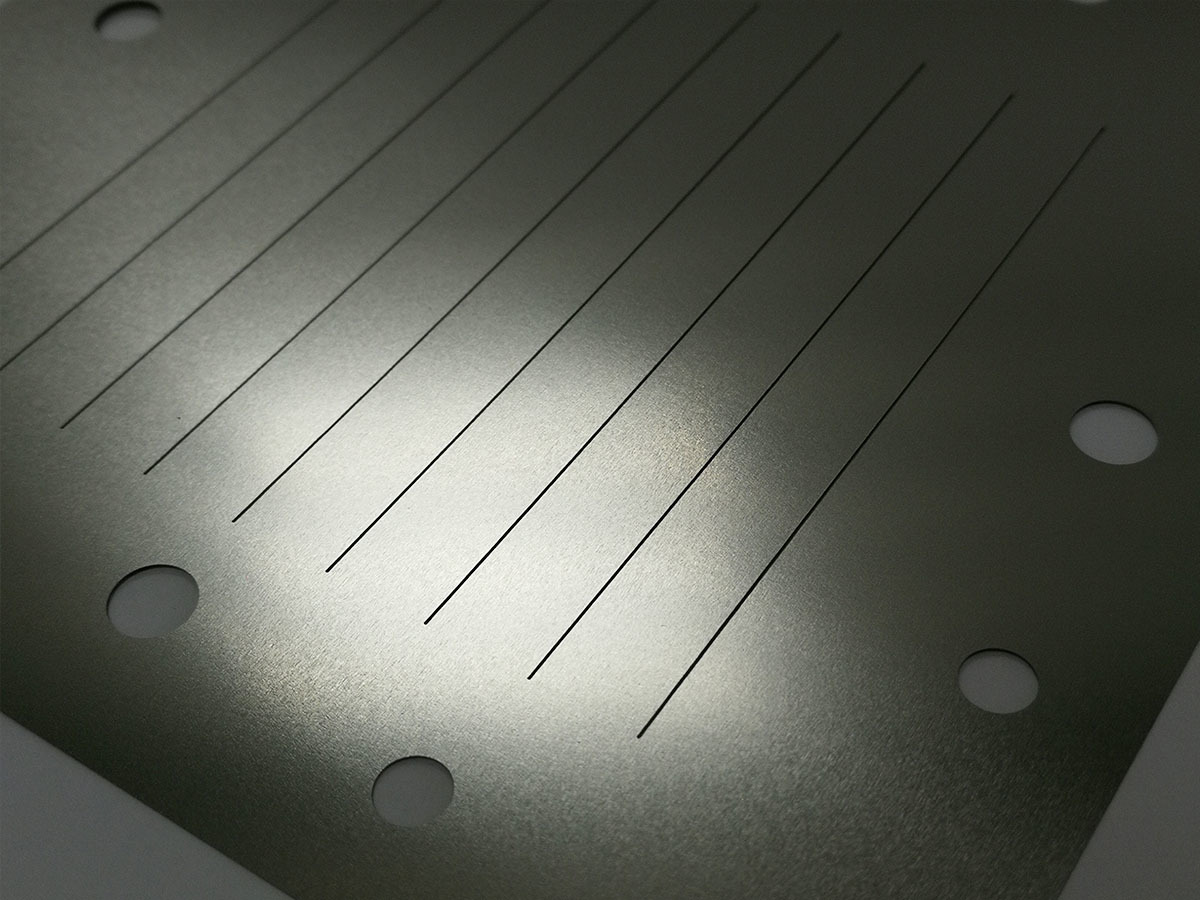

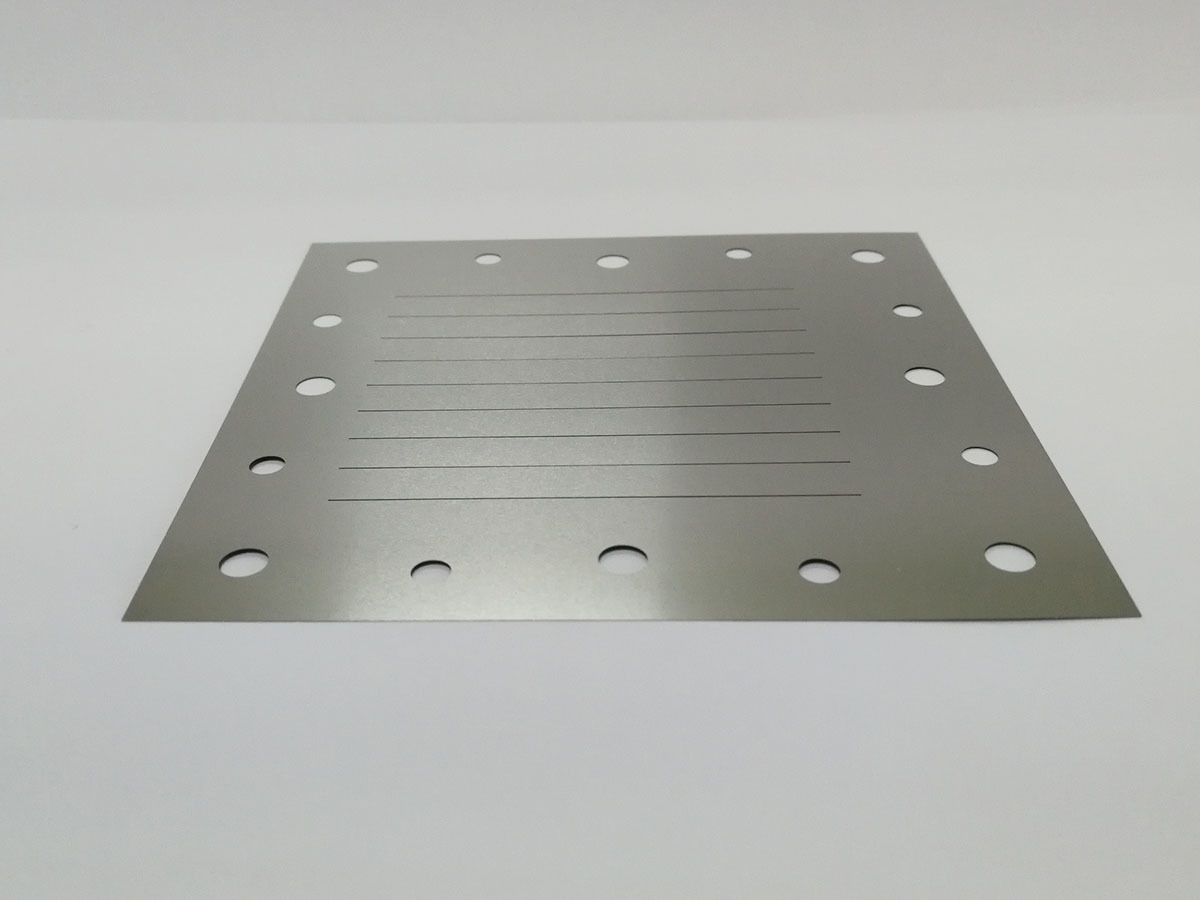

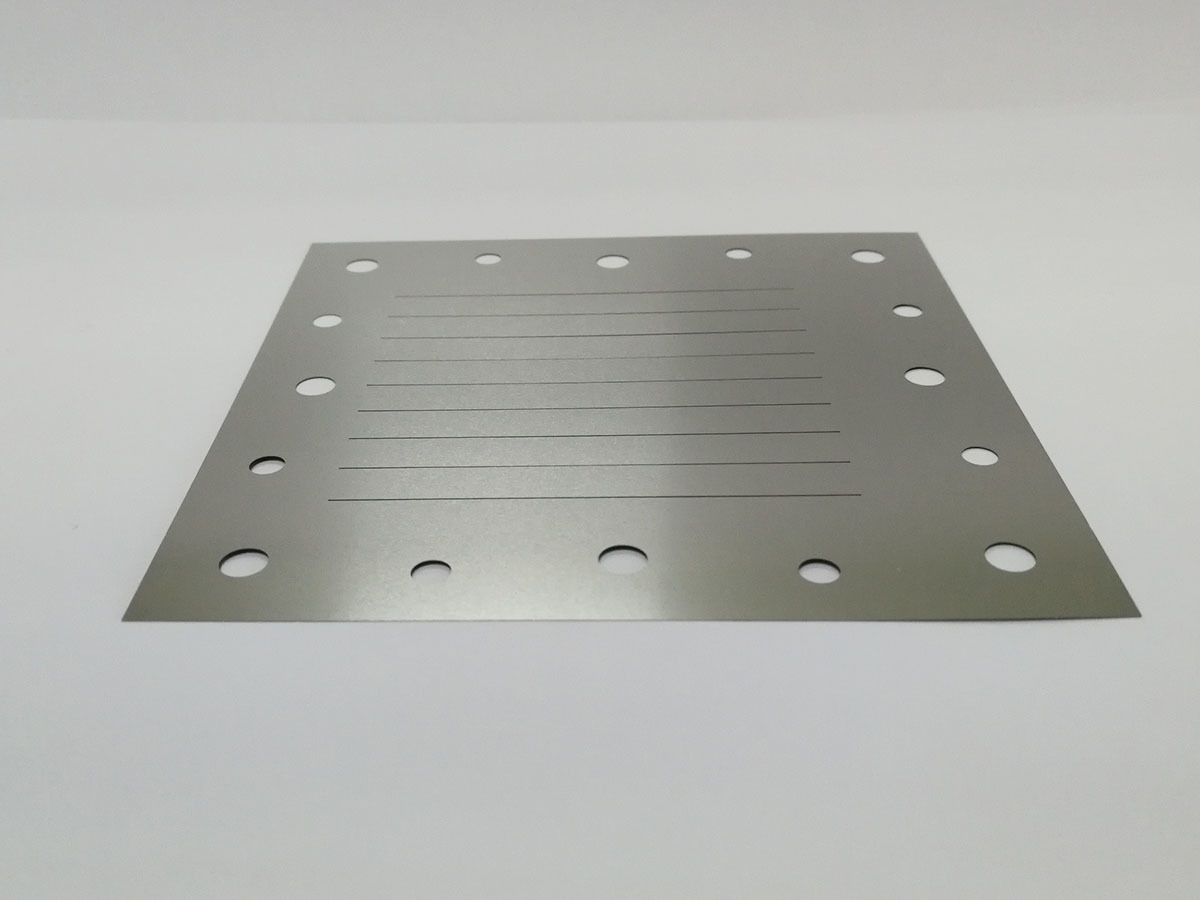

Stainless Steel Laser-Etched Grid Plate/ Customizable Products/Factory Direct/Precision Size Control

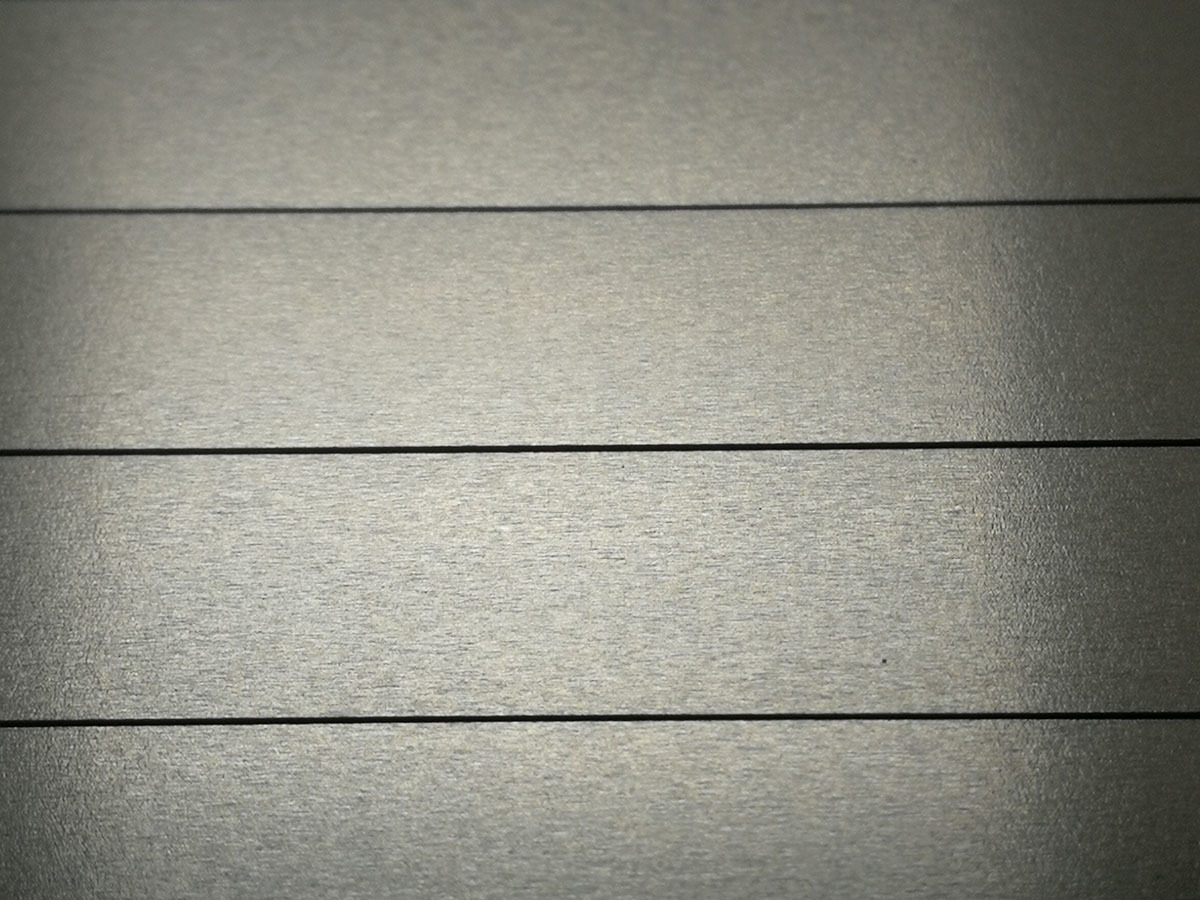

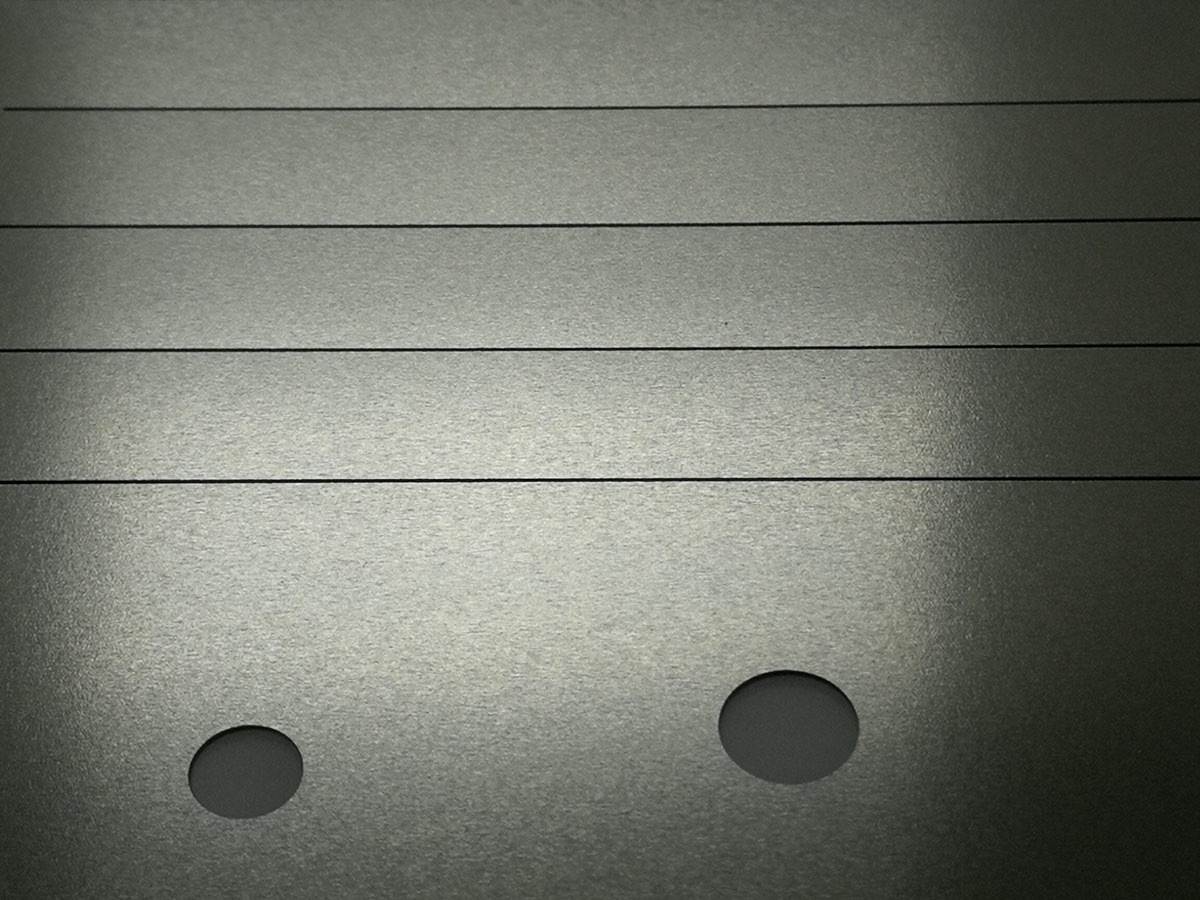

Stainless Steel Etched Grid Line / Customizable / Precision Etching from the Factory / Single or Bulk Orders Supported Product Description: Stainless steel etched grid lines are made using advanced etching technology to produce precise metal grid structures. We offer custom services and support the production of grid line products in various sizes, shapes, and specifications based on customer requirements. These are ideal for use in electronics, optoelectronics, communications, and other industries, offering high precision and excellent corrosion resistance. Material: This product is primarily made from 304 or 316 stainless steel, providing excellent corrosion resistance, high temperature resistance, and good mechanical strength, making it suitable for use in harsh environments. Quality Control Standards: Quality Management System: We strictly follow the ISO9001 quality management system for production and quality control to ensure that the products meet international standards. Multiple Testing: Each batch of products undergoes strict inspections, including appearance checks, dimensional measurements, and strength tests to ensure that products meet high-quality standards before delivery. Precision Control: Advanced precision instruments (such as CMM) are used to precisely measure hole diameter, pitch, and material thickness to ensure the product meets the required precision. Achievable Precision: 1.Hole Diameter: Accurate to 0.1mm. 2.Error Control: Hole diameter and pitch error control within ±0.05mm. 3.Hole Shape: Commonly round holes, but other shapes can be customized according to customer requirements. 4.Open Area Ratio: Open area typically ranges from 40% to 80%, customizable based on customer needs.

Key Words:

Table Parameter

| Product Name | Stainless Steel Etched Grid Line |

| Material | 304 Stainless Steel / 316 Stainless Steel |

| Hole Diameter | 0.1mm - 5mm |

| Hole Shape | Round holes or custom shapes |

| Open Area Ratio | 40% - 80% (Adjustable) |

| Material Thickness | 0.1mm - 1mm, common thicknesses: 0.2mm, 0.3mm, 0.5mm |

| Thickness Tolerance | ±0.05mm |

| Tensile Strength | ≥600MPa |

| Elongation | ≥30% |

| Hardness | 50-80 HB |

| Tensile Strength | ≥520MPa |

| Pitch | 0.2mm, 0.5mm, 1mm (Adjustable) |

| Surface Finish | Ra ≤ 0.8 µm |

| Temperature Range | -40°C to +200°C |

| Surface Treatment | Sandblasting, Brushed, Mirror, Electroplating, PVD Coating |

| Size | Custom according to customer drawing, max size: 1200mm |

| Delivery Time | 5-15 days for bulk orders (depending on quantity) |

Application Description

Stainless steel etched grid lines are widely used in the following fields:

Electronic Products: Used in the precise grid structures of circuit boards and displays.

Optoelectronic Devices: Used in grid structures for photovoltaic solar cells, electromagnetic shielding, and optical sensors.

Communication Equipment: Used in grids for high-frequency filters, antennas, and other precision devices.

Mechanical Equipment: Used in heat dissipation, protection, and other functions in fans, heat exchangers, etc.

Questions and Answers

1.What are the advantages of your etching process? 2.Complex Shapes: Etching can easily create complex shapes, holes, slits, etc., not limited to simple geometries. 3.High Production Capacity: Suitable for mass production with high consistency between batches, meeting large-scale customization demands. |

2.Can the hole diameter and hole shape be customized according to my requirements? Yes, we support customizing hole diameter, hole shape, and open area ratio based on customer needs. Common hole diameters range from 0.1mm to 5mm, and hole shapes are typically round but can be customized as needed. |

3.Do you support bulk production? Yes, our production line supports large-volume manufacturing and ensures consistency and high precision for each batch. We can deliver both small custom orders and large-scale orders on time. |

4.Can you provide samples? Yes, we can provide samples for testing based on your needs. If the samples meet your requirements, you can proceed with bulk production. |

5.What is the delivery time? Delivery time typically ranges from 5-15 days depending on quantity. For urgent orders, we can discuss advanced scheduling. |

6.What are your payment terms? As this is a custom product, full prepayment is required. We support various payment methods including: |

7.How do you handle non-conforming products? If a product does not meet your requirements, you can contact us with the specific issue, and we will replace the product free of charge in your next order. |

Factory Description

We have a full set of etching production equipment and mature processing technology. We can manufacture products in any shape with mesh sizes as small as 0.1mm, according to your requirements.

Our Advantage

Factory Direct Shipping

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Experienced Design and Manufacturing Team

We work closely with customers from the design phase to help avoid potential product flaws, ensuring both the functionality and design meet expectations.

Excellent Supply Chain Management

We can quickly adjust production schedules to meet your urgent deadlines, whether it's for large bulk orders or smaller rush orders.

OEM & ODM Support

We offer the option to print your logo or other customizations.

Strict Quality Control

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Certificate

Related Products