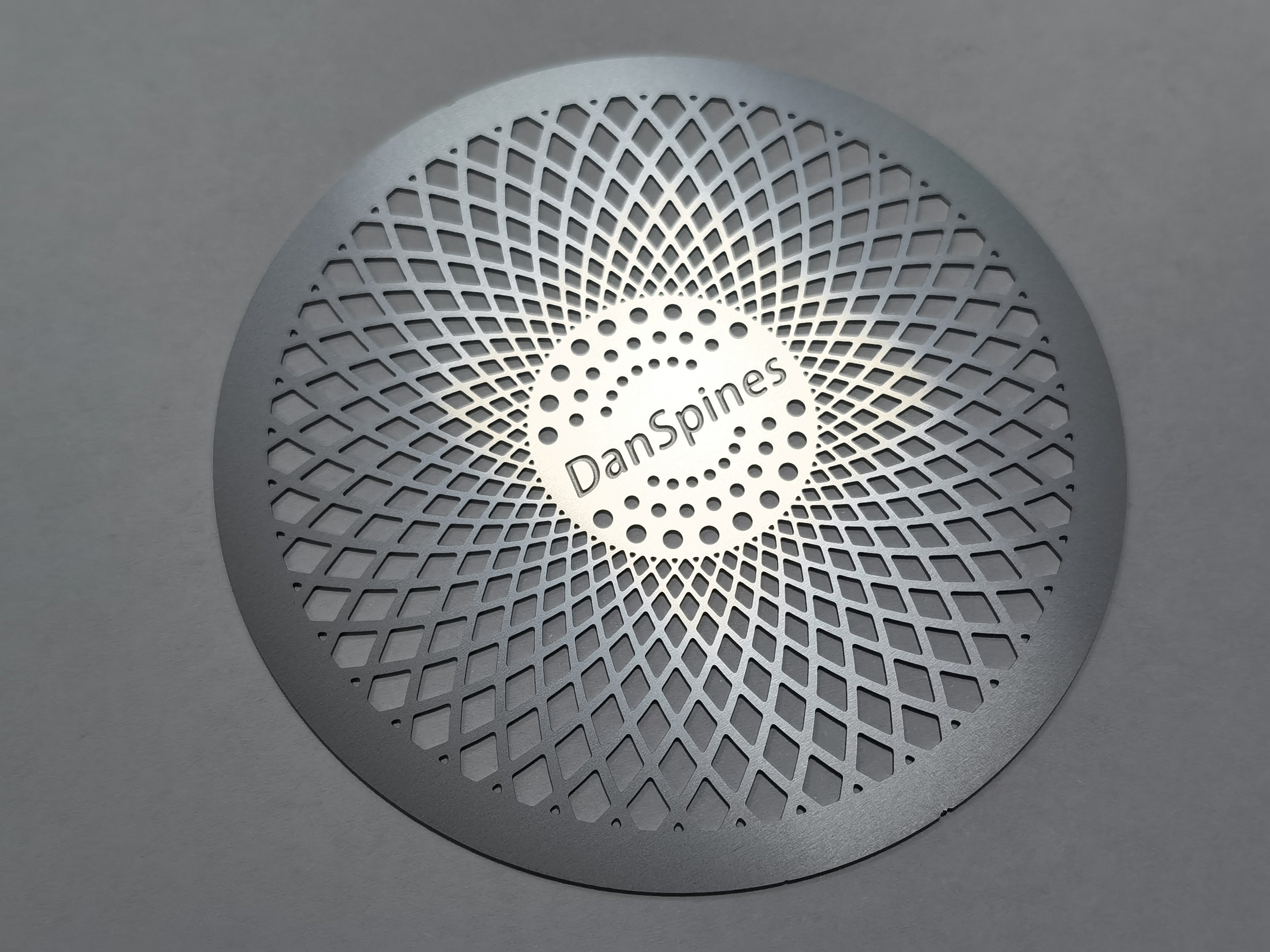

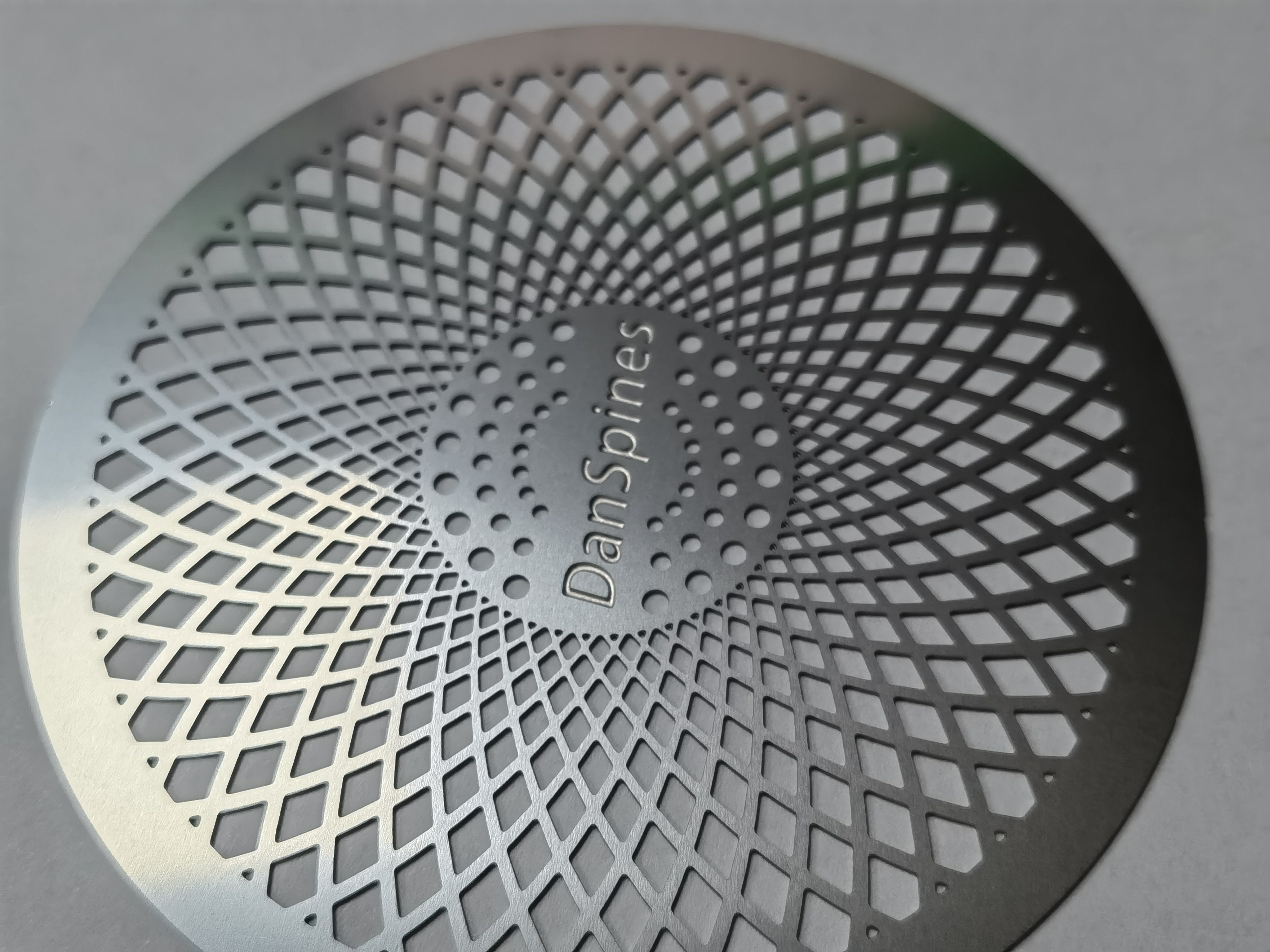

Hair Dryer Filter /Customizable Products/Factory Direct/Custom Logo

Stainless Steel Hair Dryer Inlet Mesh / Customizable / Direct Factory Source The rear inlet mesh of the hair dryer is made using high-precision stainless steel etching technology, offering both high air permeability and dust protection. It is designed to meet the structural needs of traditional hair dryers, optimizing air intake efficiency and extending the lifespan of the device. Precision Etching Technology Micro-hole Processing: Using chemical etching technology, we can achieve ultra-fine mesh holes as small as 0.1mm, far exceeding the accuracy of traditional stamping processes. This prevents metal deformation or burrs and ensures stable and uniform airflow. Customizable Complex Patterns: We support mesh hole designs in any shape, density, and arrangement to meet the special requirements of older hair dryers for air intake area and structure. Material and Durability Made from 304/316L stainless steel, it is heat-resistant, oxidation-resistant, and durable for long-term use without deformation. It is ideal for the high-temperature working environment of hair dryers. The smooth, burr-free surface minimizes dust buildup and reduces maintenance frequency. Compatibility Optimization We offer customized dimensions (such as round, square, etc.) to perfectly match non-standard rear inlet openings of older hair dryers, preventing air leakage or assembly issues.

Category:

Key Words:

Table Parameter

| Product Name | Hair Dryer Rear Inlet Mesh |

| Mold Fee | Typically ranges from $30-$140, depending on your requirements, to be confirmed after negotiation. |

| Material | 304/316 stainless steel, with excellent corrosion resistance, oxidation resistance, and mechanical strength. |

| Mesh Hole Size | Minimum 0.1mm hole size. |

| Material Thickness | Typically 0.1mm to 2.0mm. |

| Mesh Hole Shape and Arrangement | Typically round holes, customizable according to the drawing, arranged in any sequence. |

| Tolerance Range | Depending on material, thickness, and for ultra-thin materials, tolerance can be controlled as low as ±0.01mm. |

| Open Area | 15% to 80%. |

| Surface Treatment | Sandblasting, Brushed, Mirror, Plating, PVD Coloring. |

| Size | Customizable according to customer drawings (up to 1200mm). |

| Packaging | To be confirmed based on order details. |

| Minimum Order Quantity | To be confirmed. |

| Delivery Time | Depending on quantity, mass production typically takes 5-15 days. Rush orders can be negotiated in advance. |

| Price | The pricing is based on a combination of factors, including material, processing method, and order volume. |

Application Description

The rear inlet mesh of the hair dryer plays multiple roles in ensuring the proper operation of the device, including facilitating airflow, heat dissipation, dust protection, and safeguarding the internal motor.

Airflow and Heat Dissipation: The rear inlet mesh helps the hair dryer intake air, ensuring internal airflow. It provides cooling air to the motor to prevent overheating and extend the lifespan of the hair dryer.

Dust Protection: The fine mesh structure of the inlet mesh effectively prevents dust, hair, and other small particles from entering the hair dryer, reducing damage to the motor and other internal components, thus maintaining the cleanliness of the device.

Efficiency Improvement: By maintaining a stable airflow, the inlet mesh ensures the hair dryer's working efficiency. Unstable airflow or obstructions may degrade performance or even lead to overheating.

Motor Protection: The mesh also serves to protect the motor from external objects (such as hair or small debris), preventing damage to the motor or internal circuitry.

Inlet meshes are also widely used in devices like vacuum cleaners, filters, water purifiers, compressors, coffee machines, air purifiers, fans, centrifuges, etc.

Questions and Answers

| Q1: What is the production cycle for custom products? Is expedited production available? Standard Process: Sample production takes 3-5 working days after confirming the drawings/samples, and mass production takes 7-15 working days (depending on order size and process complexity). Expedited Service: Expedited production is available, with the fastest delivery in 3-5 days (subject to process feasibility), with additional charges based on the order situation. |

| Q2: How do you ensure the stainless steel mesh does not deform or get damaged during transportation? Packaging Plan: Individual products are wrapped with bubble film and hard corner protectors to prevent surface scratches. Bulk shipments are fixed with custom vacuum-formed trays or wooden crates to prevent compression damage. For export orders, additional moisture-proof film and fumigated wooden boxes are used, meeting international shipping standards. Shipping Method: We support express (small orders), land transport (dedicated logistics), sea/air freight (containerized or LCL). |

| Q3: Are there minimum order quantities (MOQ) for custom patterns or special sizes? Regular Orders: MOQ is 500 pieces (same specification). Special Custom Orders: MOQ for complex patterns or ultra-thin/ultra-thick materials (such as 0.1mm or 2.0mm) can be negotiated to 100-300 pieces. Sample Service: Small batch samples (1-5 pieces) are available for confirmation before mass production. |

| Q4: How do you ensure the hole accuracy and consistency of the stainless steel mesh? Technical Guarantee: We use fully automated optical positioning etching equipment, with tolerance control within ±0.02mm. Each production batch undergoes laser detection of the first piece, and hole size and open area are checked every 2 hours during mass production. Free samples are provided for customer verification before mass production. |

| Q5: Does the product come with quality certifications or after-sales support? Certifications: We provide material inspection reports (SGS), salt spray testing reports, and RoHS certifications. Quality Commitment: Products are fully inspected before shipment, with a one-year warranty. Any defective products due to process issues can be reworked or replaced. |

| Q6: Do you require design files? What formats are supported? File Requirements: CAD drawings (.dwg/.dxf) or vector graphics (.ai/.eps) with key parameters such as hole diameter, hole spacing, and external dimensions. Design Assistance: If no design files are available, we can reverse-engineer samples or provide free layout solutions based on customer needs. |

| Q7: What is the tolerance of your etching process? Standard Precision: The tolerance is generally controlled within ±0.05mm to ±0.1mm. This is suitable for commonly used metals and materials with thicknesses ranging from 0.1mm to a few millimeters. High-Precision Etching: For more demanding customer requirements, we can offer higher precision control, with tolerance ranging from ±0.01mm to ±0.05mm. This level of precision is ideal for products with stringent dimensional specifications. |

| Q8: Will there be burrs in the etching process? Etching ensures the selection of appropriate metal materials (such as stainless steel, aluminum alloy, or copper), resulting in smooth mesh surfaces and preventing sharp edges or burrs. |

| Q9: What is the smallest hole size you can achieve? What shape are the holes, and how can they be arranged? The hole size can be customized according to the customer's requirements. Generally, assuming a material thickness of 0.1mm, holes with a diameter or side length larger than 0.3mm can be relatively easily processed into square shapes. For smaller sizes (such as below 0.2mm), due to the flow characteristics of the etching solution and technical limitations, round holes are easier to achieve. The holes can be arranged in any shape and pattern according to your drawings. |

| Q10: What are your payment methods? As this is a custom product, full payment is required in advance. We support various payment methods, including: Letter of Credit (L/C) Telegraphic Transfer (T/T) PayPal (for small orders) Western Union (for certain countries) Alipay/WeChat Pay (for some countries) We can select the most suitable payment method based on your requirements. Bank Transfer |

Factory Description

We have a full set of etching production equipment and mature processing technology. We can manufacture products in any shape with mesh sizes as small as 0.1mm, according to your requirements.

Our Advantage

Factory Direct Shipping

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Experienced Design and Manufacturing Team

We work closely with customers from the design phase to help avoid potential product flaws, ensuring both the functionality and design meet expectations.

Excellent Supply Chain Management

We can quickly adjust production schedules to meet your urgent deadlines, whether it's for large bulk orders or smaller rush orders.

OEM & ODM Support

We offer the option to print your logo or other customizations.

Strict Quality Control

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Certificate

Related Products