Automotive Engine Oil Filter Mesh/Customizable Products/Factory Direct/Precision Mesh

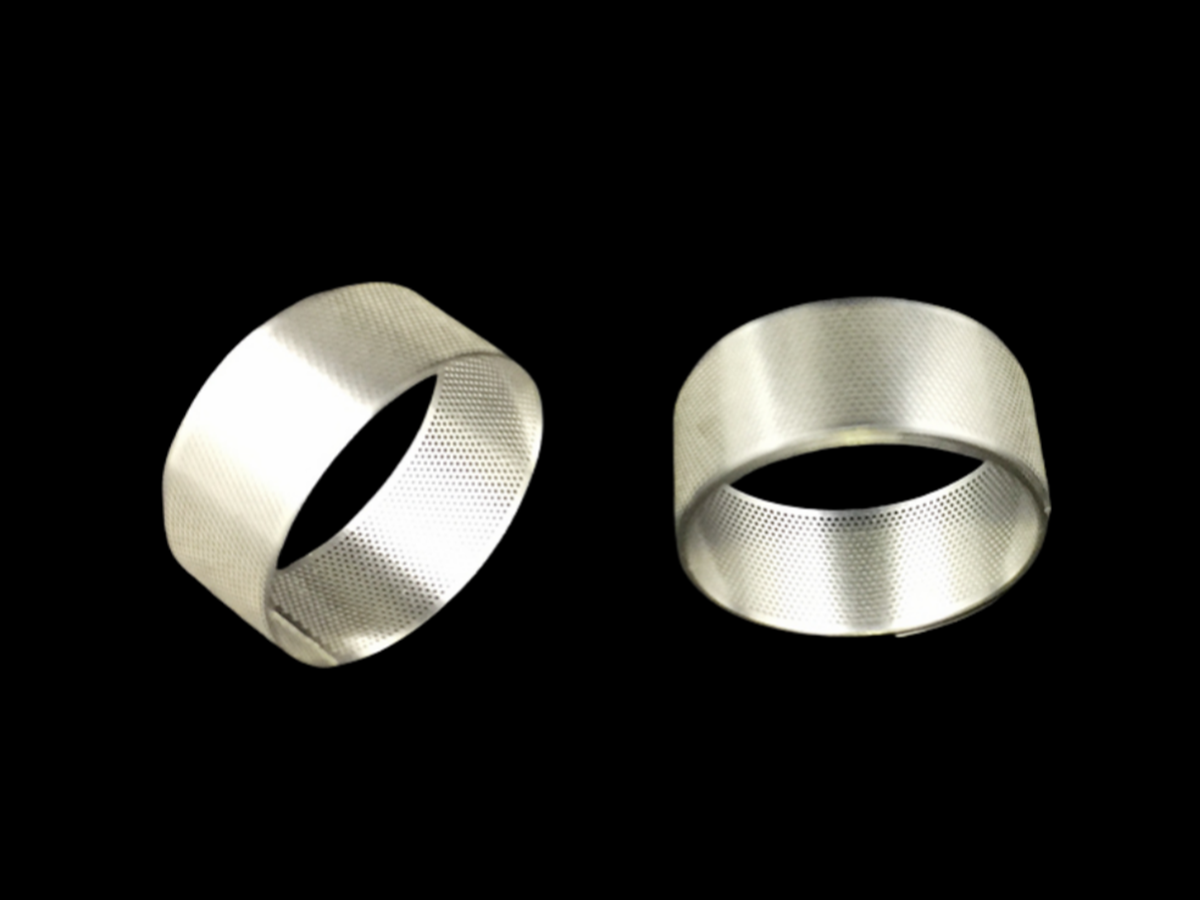

Automotive Engine Oil Filter Mesh / Customizable / Etching Process / High Precision Material Selection: Based on customer requirements, we typically use high-quality stainless steel (304, 316L) and other corrosion-resistant materials to ensure excellent performance in harsh automotive environments, including high-temperature, wear-resistant, and corrosion-resistant properties. Etching Process: Using precision etching technology, we employ acid etching to create uniform and fine mesh structures. Uniform Aperture Size: The etching process can manufacture apertures as small as 0.1mm, accurately controlling the filtration capability to ensure optimal oil filtration while maintaining flow rate. High-Precision Tolerance Control: Our process maintains an aperture tolerance of ±0.02mm, ensuring consistent filtration performance for each product. Surface Treatment: The final surface treatment ensures a smooth, burr-free mesh, allowing smooth oil flow and enhanced durability. Testing & Quality Control: We perform 100% inspection to ensure that every batch of products meets strict quality standards. Parameters checked include aperture size, hole spacing, material thickness, and surface finish.

Category:

Key Words:

Table Parameter

| Product Name | Automotive Engine Oil Filter Mesh |

| Mold Fees | Typically between $30 - $140, depending on specific requirements |

| Material | 304/316 Stainless Steel, with excellent corrosion resistance, oxidation resistance, and mechanical strength |

| Mesh Aperture Size | Can process apertures as small as 0.1mm |

| Material Thickness | Generally 0.1mm - 2.0mm |

| Mesh Aperture Shape & Arrangement | Etching typically produces round apertures with uniform diameters; apertures can be arranged in any sequence according to your design |

| Tolerance Range | Based on material thickness, the machining precision is approximately 10% of the material thickness |

| Open Area | 15% - 80% |

| Surface Treatment | Sandblasting, oxidation, electroplating, PVD coloring, etc. |

| Size | Customized according to customer drawings (maximum size: 1200mm) |

| Packaging | Custom packaging (details upon request) |

| Minimum Order Quantity (MOQ) | To be negotiated |

| Delivery Time | For bulk orders, production typically takes 7-15 days, expedited orders can be discussed in advance |

| Pricing | Pricing is based on various factors, including material type, processing technology, and order volume |

Application Description

Our etching technology can control the aperture tolerance to ±0.02mm, meeting industry standards. We strictly control material quality to ensure that the filter mesh can withstand high temperatures and pressure fluctuations without deformation or loss of function. The etched precision mesh ensures smooth oil flow, without restricting oil flow, preventing impact on engine performance.

Precision stainless steel filter mesh produced using etching technology provides the following functions:

Impurity Filtration: The main function of the oil filter mesh is to remove impurities such as dust, debris, and metal chips from engine oil, preventing damage to engine components.

Oil Flow Regulation: The mesh ensures smooth oil flow within the engine, maintaining optimal oil pressure and circulation.

Wear Reduction: By filtering out impurities, the mesh reduces friction between engine parts, extending the engine’s lifespan.

Questions and Answers

| Q1: How long is the production cycle for custom products? Is expedited service available? Standard Process: After confirming the drawings/samples, sample lead time is 3-5 business days, and mass production takes 7-15 business days (depending on order quantity and process complexity). Expedited Service: Expedited production is available, with a lead time as short as 3-5 days (subject to process feasibility confirmation). Expedited charges depend on the order specifics. |

| Q2: How do you ensure the stainless steel mesh doesn’t get deformed or damaged during transportation? Packaging: Single items are wrapped in bubble wrap with rigid corner protectors to prevent surface scratches. Bulk goods are fixed using custom blister trays or wooden crates to avoid compression and deformation. Export orders are additionally wrapped with moisture-proof film and fumigated wooden boxes to meet international shipping standards. Shipping: We support express (for small quantities), land transport (dedicated logistics), and sea/air freight (full container or less-than-container load). |

| Q3: What advantages does etching have over traditional stamping or laser cutting? Project Chemical Etching Stamping/Laser Cutting Precision ±0.02mm, burr-free micro-holes ±0.1mm, edges may have burrs Material Applicability Thin materials (from 0.05mm) with no deformation Suitable for thick materials, thin materials can tear Complex Patterns Supports any pattern, including gradient density Primarily simple, regular patterns Cost Efficiency Lower cost, faster lead times High mold costs |

| Q4: How do you ensure the accuracy and consistency of the apertures in the stainless steel mesh? Technical Guarantee: We use fully automated optical positioning etching equipment with tolerance control within ±0.02mm. Pre-production checks: Laser inspection of the first item before production, with random aperture and open-area checks every two hours during mass production. Free Samples: Free samples provided for customer validation before mass production. |

| Q5: Does the product come with after-sales support? If defects are caused by process issues, we support unconditional rework or remake and can provide free replacement in the next order. |

| Q6: Do you need to provide design files? What formats are supported? File Requirements: CAD drawings (.dwg/.dxf) or vector files (.ai/.eps), with key parameters like aperture size, hole spacing, and dimensions clearly marked. Design Assistance: If design files are not available, we can reverse engineer from samples or provide layout suggestions based on customer needs. |

| Q7: What is the smallest mesh aperture you can achieve? We can achieve a minimum aperture size of 0.1mm, with thinner materials (e.g., 0.05mm thick stainless steel) achieving even smaller apertures, such as 0.08mm. |

| Q8: Will there be burrs from the etching process? Etching ensures that the appropriate metal materials (such as stainless steel, aluminum alloy, or copper) are chosen to guarantee a smooth surface, preventing sharp edges or burrs. |

| Q9: What kind of mesh arrangements can be achieved? We can customize different grid arrangements according to your needs, including irregular and arbitrary arrangements. |

| Q10: What are your payment terms? As it is a custom product, full payment is required upfront. We support various payment methods, including: Letter of Credit (L/C) Wire Transfer (T/T) PayPal (for small orders) Western Union (for some countries) Alipay/WeChat Pay (for some countries) Bank Transfer |

Factory Description

We have a full set of etching production equipment and mature processing technology. We can manufacture products in any shape with mesh sizes as small as 0.1mm, according to your requirements.

Our Advantage

Factory Direct Shipping

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Experienced Design and Manufacturing Team

We work closely with customers from the design phase to help avoid potential product flaws, ensuring both the functionality and design meet expectations.

Excellent Supply Chain Management

We can quickly adjust production schedules to meet your urgent deadlines, whether it's for large bulk orders or smaller rush orders.

OEM & ODM Support

We offer the option to print your logo or other customizations.

Strict Quality Control

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Certificate

Related Products