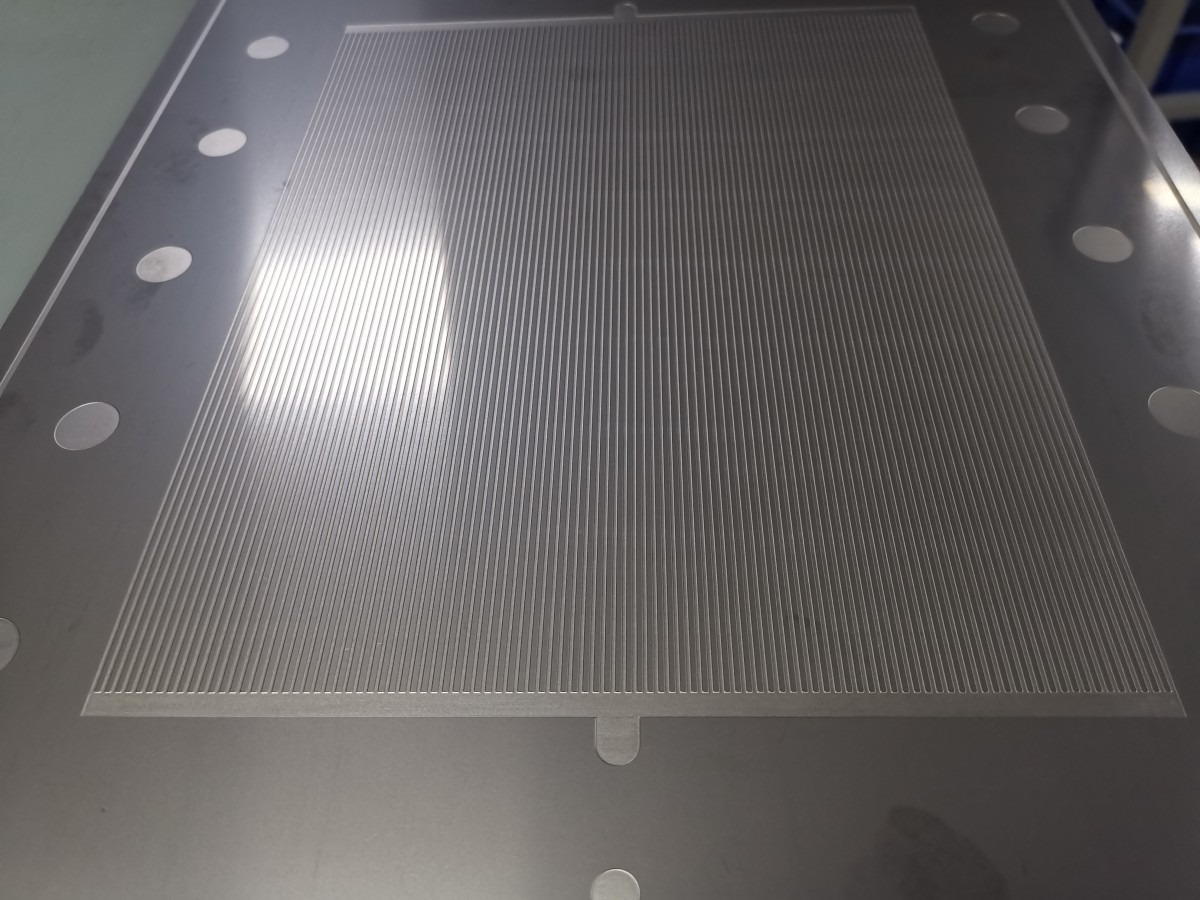

Bipolar Plate Microchannel/Customizable Products/Factory Direct/Precision Mesh

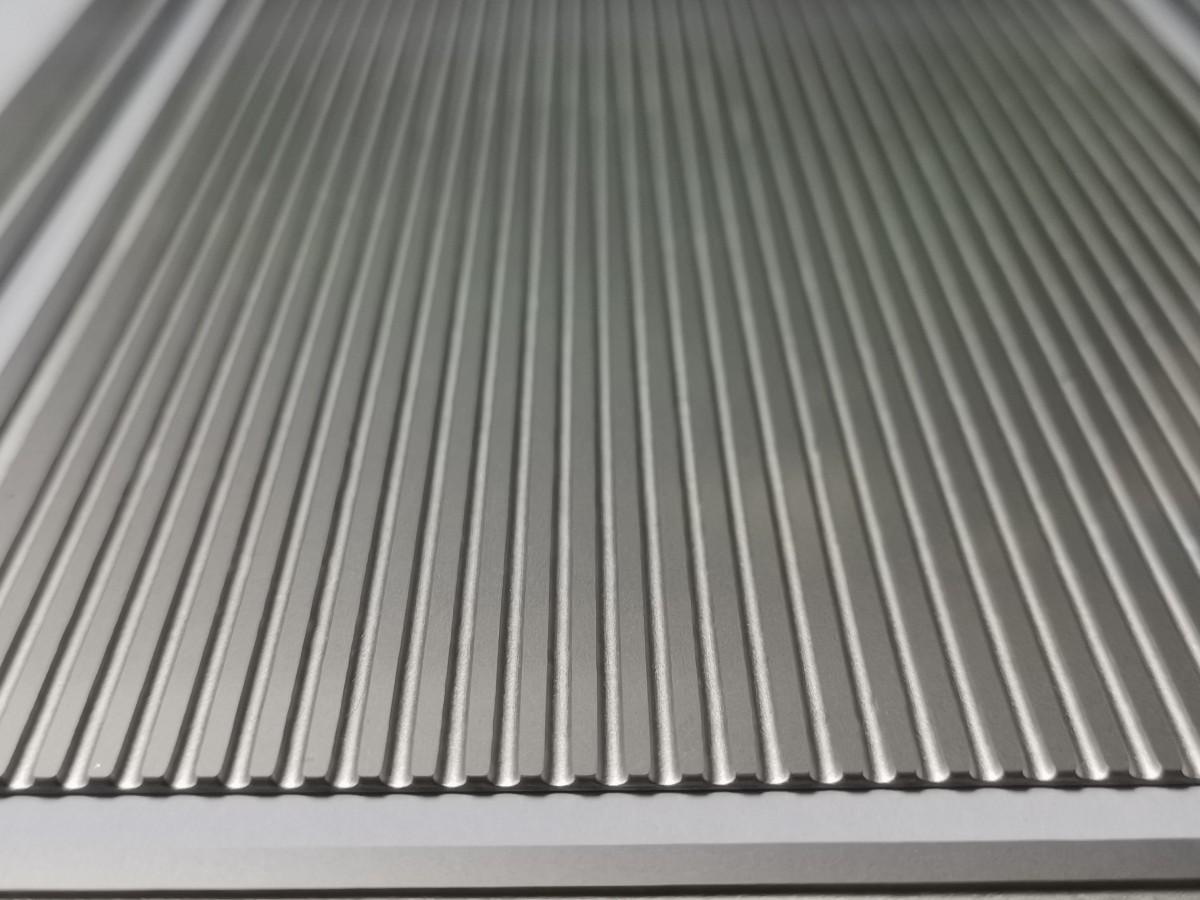

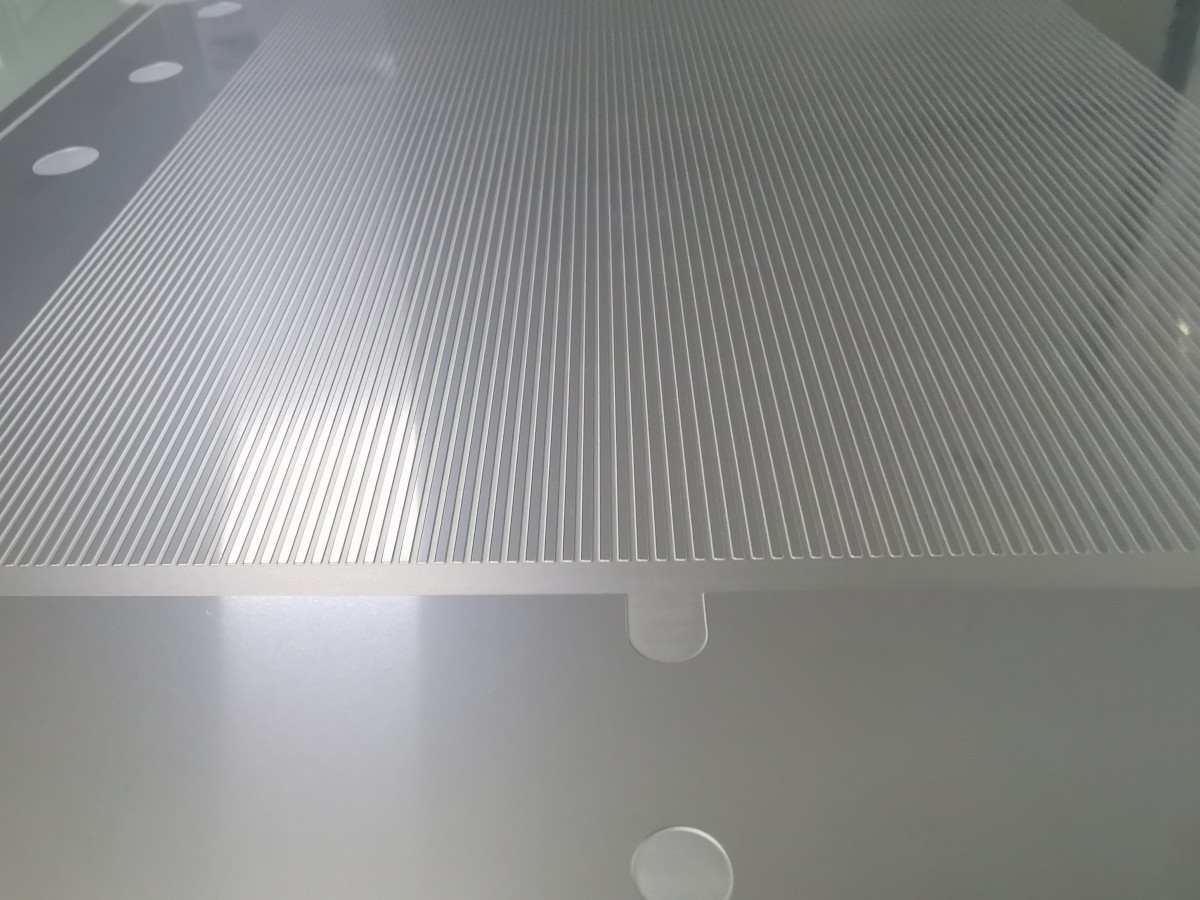

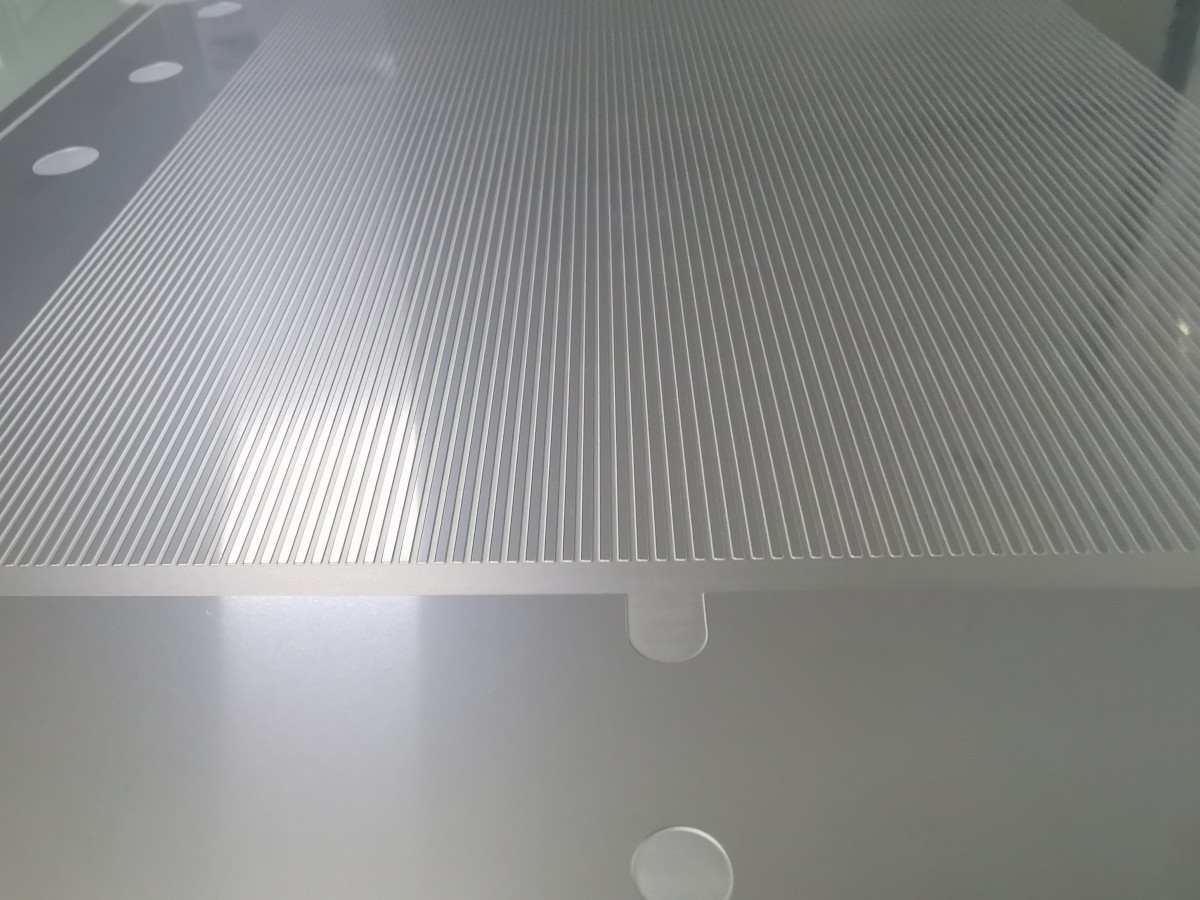

Bipolar Plate Microchannel / Customizable / Direct Factory Source / Precision Etching The bipolar plate microchannel is a core functional component processed through precision etching technology. It is widely used in fuel cells, chemical micro-reactors, electronic heat exchangers, medical devices, and other fields. The core function is to achieve efficient mass transfer, heat transfer, or fluid distribution through high-precision microchannel designs, meeting stringent industrial performance requirements. High Precision Control: 1.Minimum etching aperture: 0.05mm 2.Channel width precision: ±0.01mm, aspect ratio up to 1:10. 3.Surface roughness: Ra 0.10-0.4μm (better than traditional machining). Uniformity and Consistency: Manufactured using fully automated etching lines, with a yield rate ≥99% and batch consistency ±3%. No Mechanical Stress: The etching process avoids material deformation or burrs caused by stamping or CNC machining, ensuring the integrity of the microchannel structure. Adaptability for Complex Patterns: Supports serpentine, parallel, tree-like, and other custom flow path designs, catering to the needs of fuel cell bipolar plates, micro-reactors, etc.

Key Words:

Table Parameter

| Product Name | Bipolar Plate Microchannel |

| Processing Method | Common processing methods include metal etching, laser cutting, water jet cutting, CNC machining, milling and turning, heat treatment, and surface treatment. |

| Material | Supports stainless steel, titanium alloy, copper, nickel-based alloys, etc. |

| Machinable Shapes | Almost any shape. Depending on material thickness, the minimum aperture and groove that can be processed vary. Thicker plates require larger shape gaps. Complex shapes can also be etched without additional cost. |

| Precision Control | If your requirements are high, our etching process can achieve effects that stamping, cutting, or CNC cannot, such as logos, brand markings, etc., with strong 3D effects, arbitrary patterns, and high precision. |

| Tolerance | Based on material type and thickness, our processing accuracy is typically around 10% of the material thickness. For example, a 0.1mm thick stainless steel can be controlled within ±0.01mm. |

| Packaging | - |

| Minimum Order Quantity | - |

| Lead Time | For batch production, the processing time generally ranges from 5-15 days, depending on the order quantity. In special cases, if the delivery deadline is tight, we can discuss earlier arrangements. |

| Price | Overall product pricing is determined by multiple factors, including material type, processing method, and order volume. |

Application Description

| Field | Typical Application | Key Quality Requirements |

| Fuel Cells | Bipolar plate gas/liquid hydrogen flow channels | Dimensional accuracy ±0.05mm, gas tightness ≤0.1sccm/cm², corrosion resistance (ASTM B117 salt spray test for 500 hours) |

| Chemical Micro-Reactors | Efficient mixing and reaction channels | Channel depth uniformity ±3%, resistance to strong acid/alkali corrosion (e.g., Hastelloy C276 material) |

| Electronics Cooling | Chip-level microchannel cooling plates | Heat transfer channel wall thickness ≤0.1mm, thermal resistance ≤0.1°C/W |

| Medical Devices | Microfluidic chips, drug delivery systems | Biocompatibility certification (ISO 10993), no residual chemical contamination |

Questions and Answers

| Q1: What are the advantages of using etching technology? Cost-Effective: No mold required, reducing the cost of small batch customizations by over 50%. Ultra-Thin Processing: Supports ultra-thin material processing (down to 0.05mm), avoiding the tearing risks associated with traditional stamping. Eco-Friendly: Etching waste liquid recycling rate of 90%, compliant with RoHS/REACH standards. |

| Q2: What is the minimum aperture and tolerance range for the bipolar plate microchannel? Minimum Aperture: 0.05mm, Tolerance: ±0.01mm, Depth tolerance: ±5%. |

| Q3: What is the design process for custom microchannels? Provide drawings or requirements → Feasibility analysis → Photomask production → Sample testing (12 weeks) → Mass production. |

| Q4: Do you support difficult-to-machine materials like titanium alloys? Yes, we support stainless steel, titanium alloys, copper, nickel-based alloys, etc. Thickness ranges from 0.05mm to 2.0mm. Titanium alloy etching requires special formulas, leading to a 35-day extended delivery time. |

| Q5: How do you ensure consistency in mass production? We use fully automated etching lines, with full inspection of the first, middle, and last pieces in each batch (dimensional accuracy, roughness, gas tightness), and traceable data archiving. |

| Q6: What are the advantages of etching compared to laser processing? No heat-affected zones, avoiding material carbonization. Suitable for complex patterns. Cost reduction of more than 30% (no point-by-point engraving). |

| Q7: Can you provide high-pressure test reports? Yes, we can provide third-party certified burst pressure tests (up to 50 Bar) and helium mass spectrometry leak detection (sensitivity of 1×10⁻⁹ mbar·L/s). |

Factory Description

We have a full set of etching production equipment and mature processing technology. We can manufacture products in any shape with mesh sizes as small as 0.1mm, according to your requirements.

Our Advantage

Factory Direct Shipping

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Experienced Design and Manufacturing Team

We work closely with customers from the design phase to help avoid potential product flaws, ensuring both the functionality and design meet expectations.

Excellent Supply Chain Management

We can quickly adjust production schedules to meet your urgent deadlines, whether it's for large bulk orders or smaller rush orders.

OEM & ODM Support

We offer the option to print your logo or other customizations.

Strict Quality Control

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Certificate

Related Products