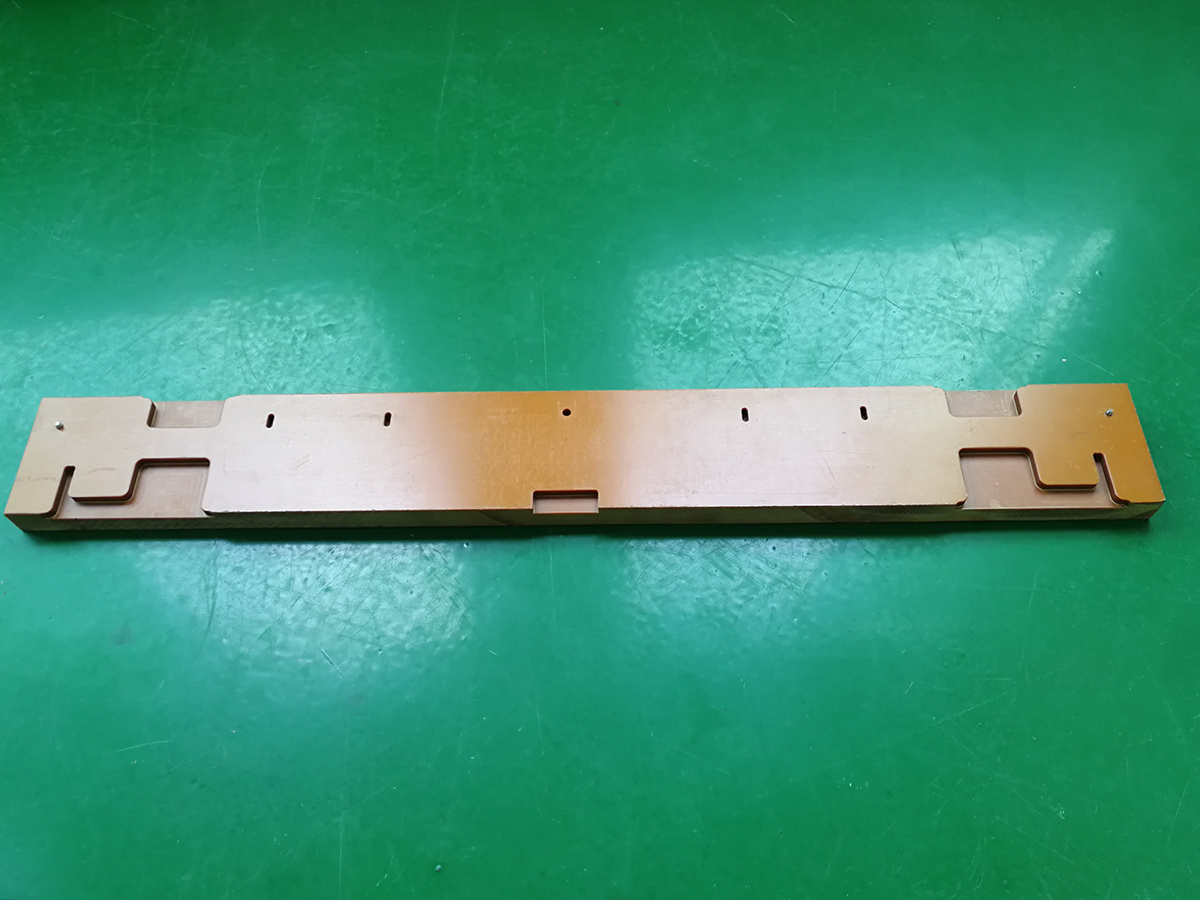

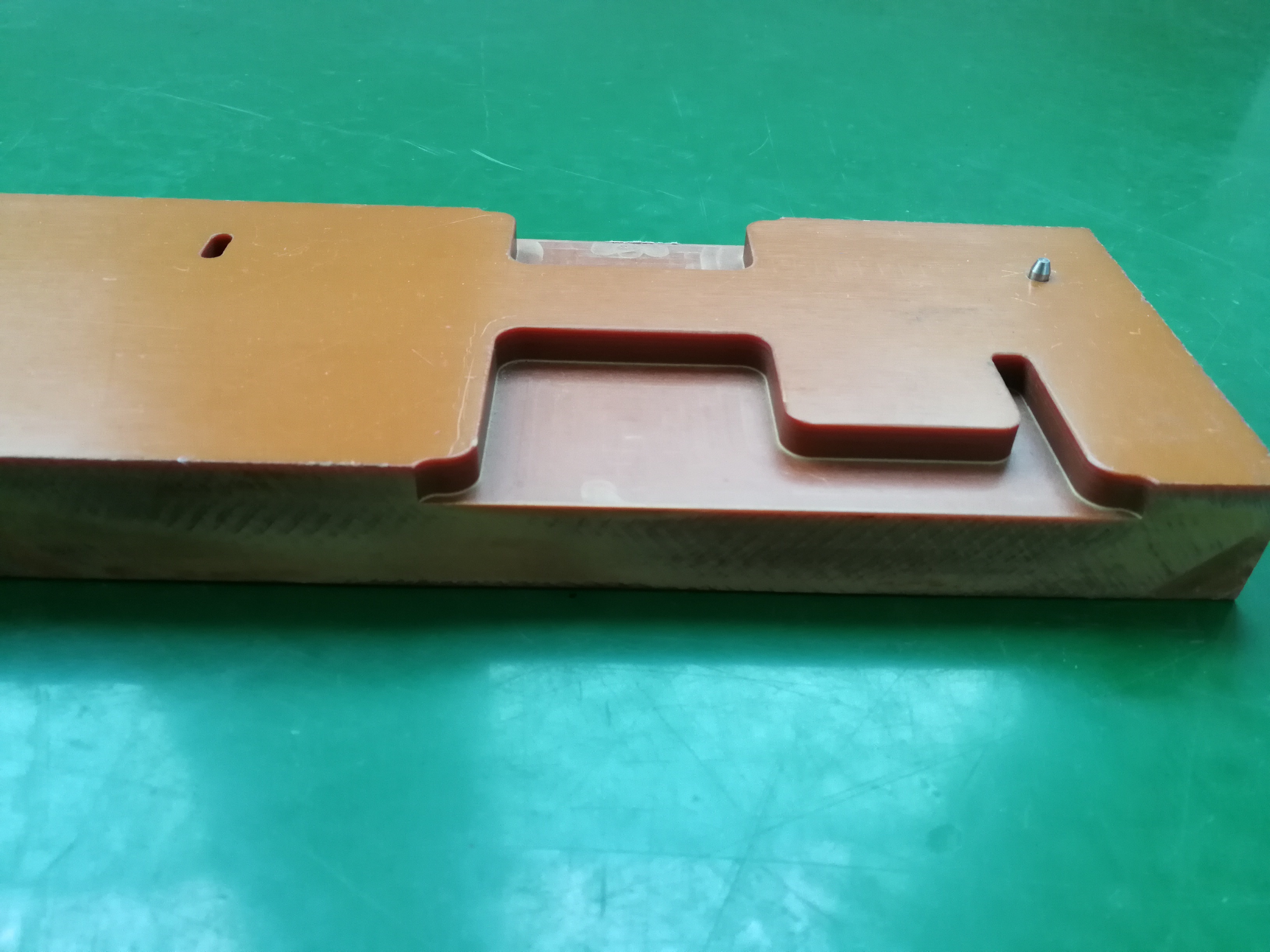

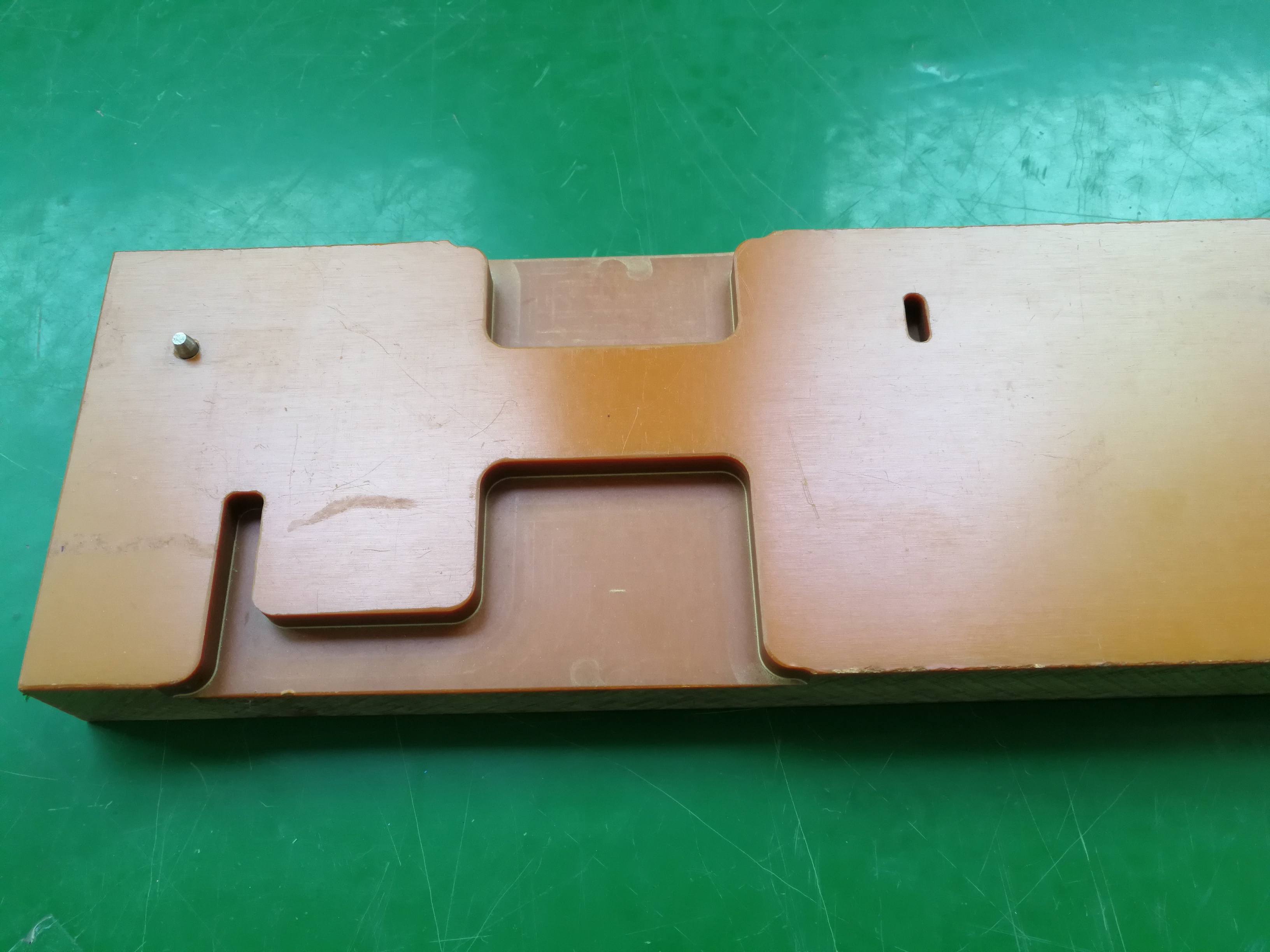

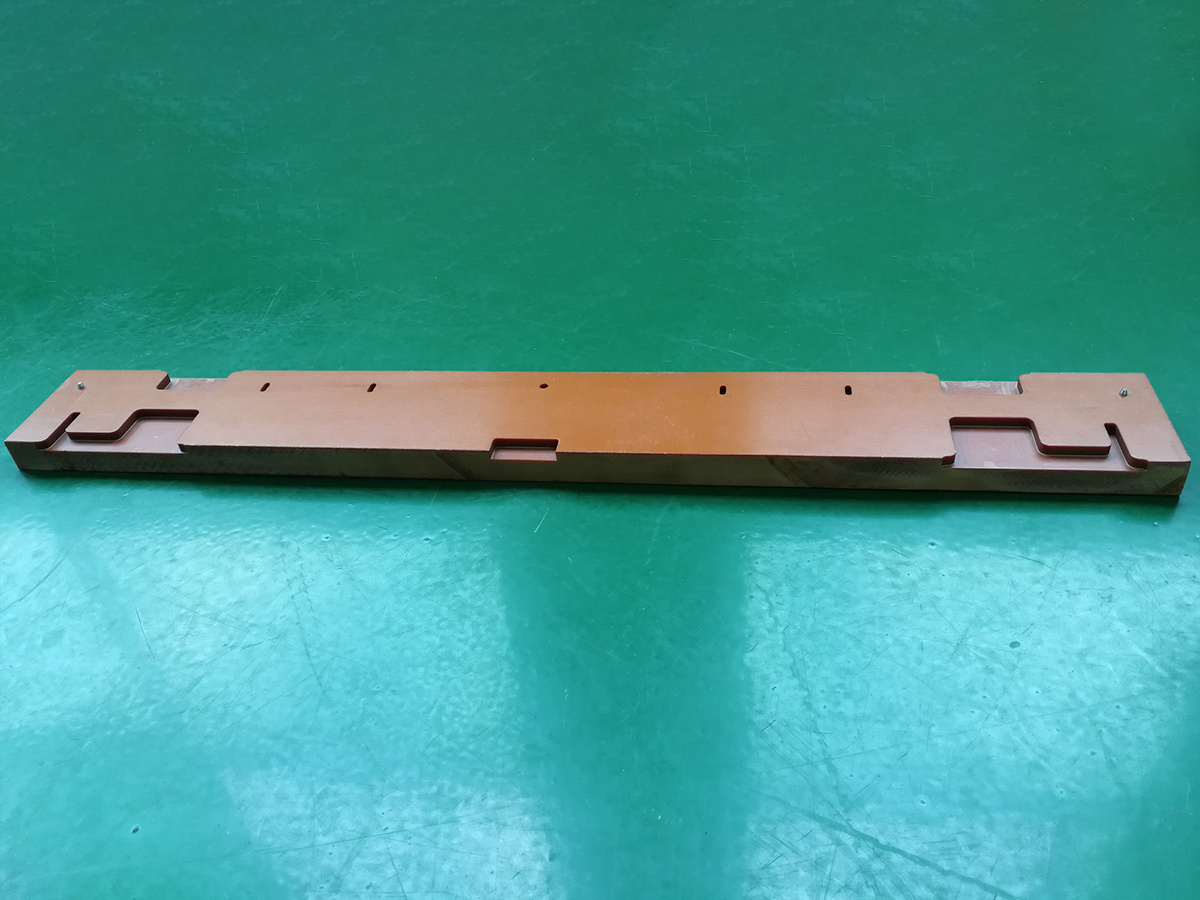

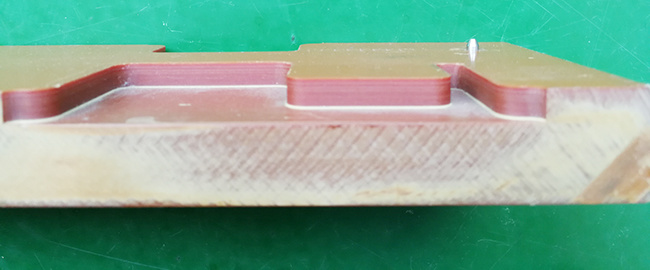

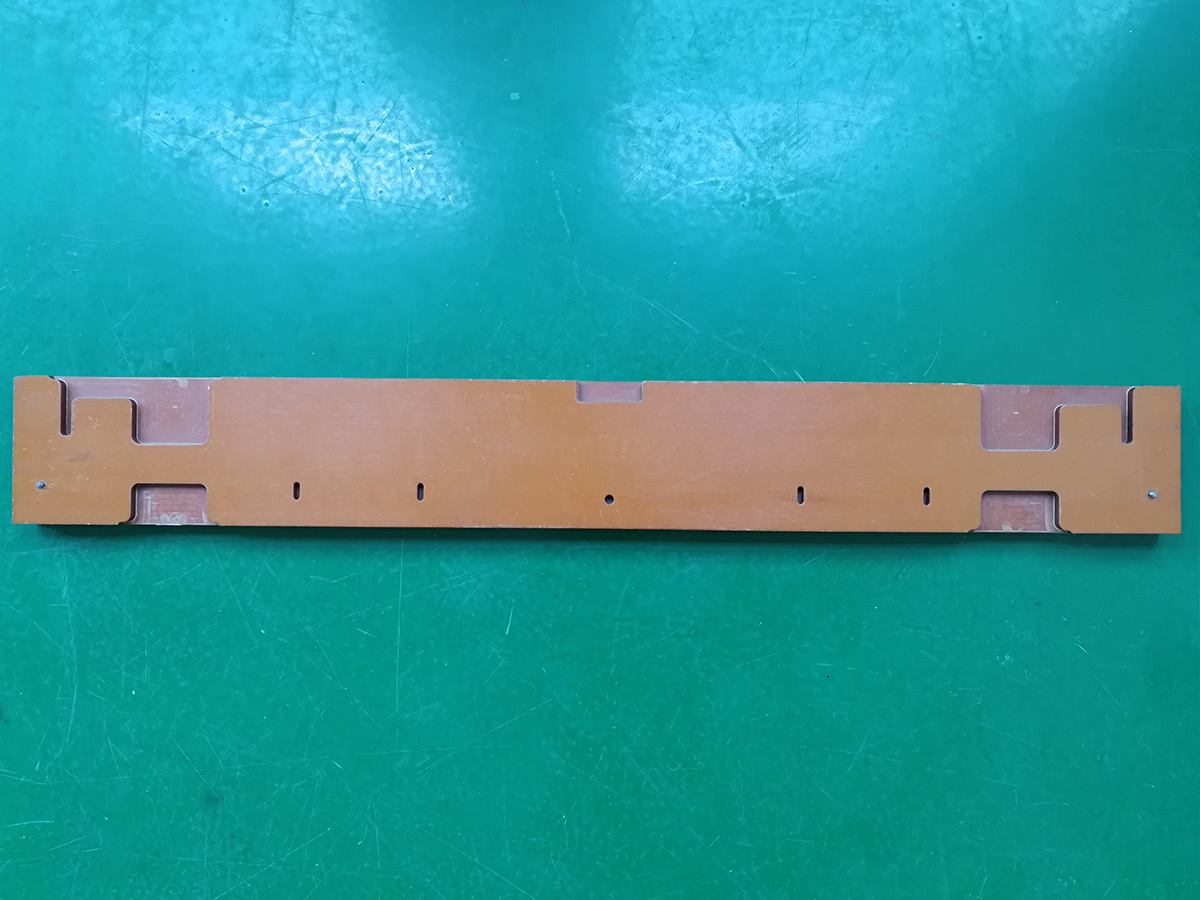

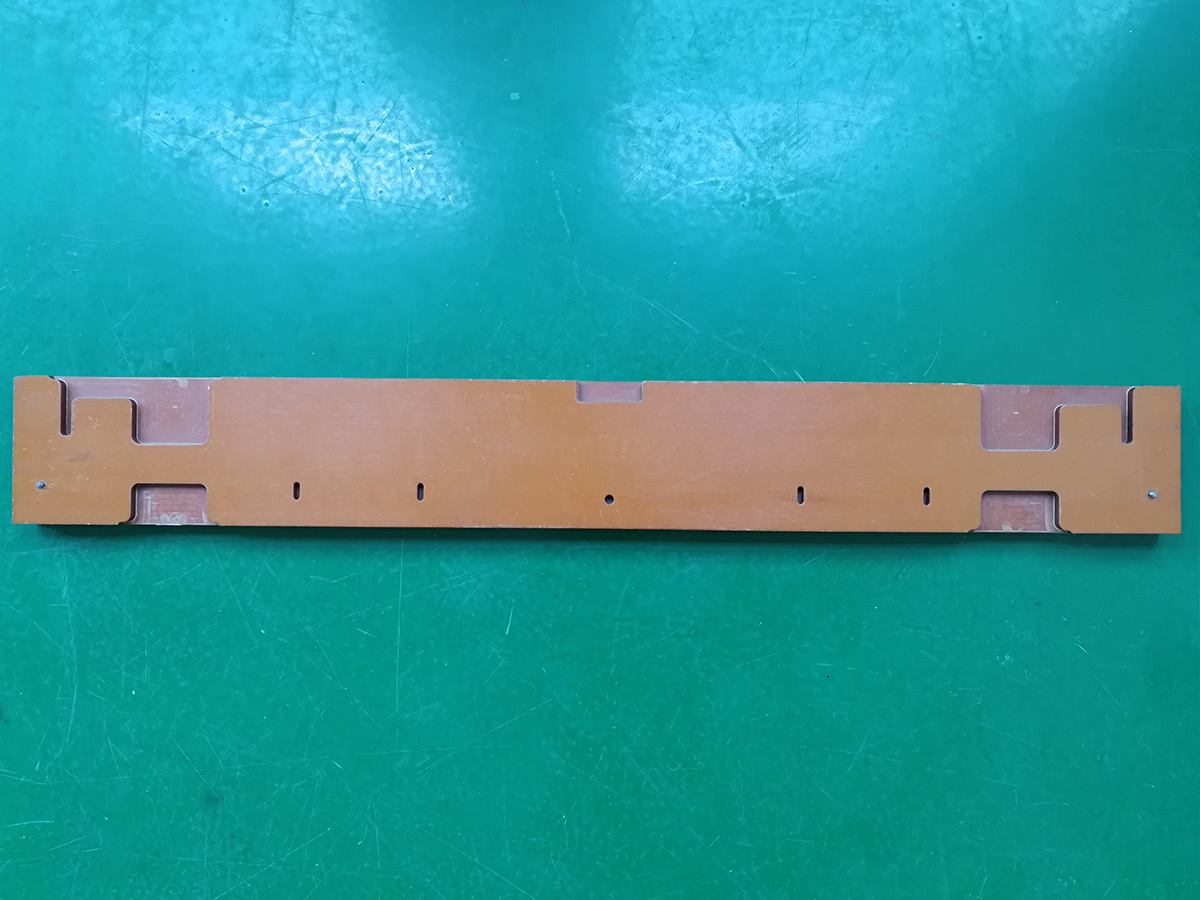

Bakelite Jig/Customizable Products/Factory Direct/Precision Size Control

Bakelite Jig / Precision CNC Machining / Customizable / Factory Direct Shipping Material: The commonly used material is Bakelite (also known as phenolic resin board), which has high strength, excellent electrical insulation, heat resistance, and corrosion resistance. We can customize Bakelite materials in various thicknesses and performances according to customer requirements. Production Process: The Bakelite jigs are processed with advanced CNC machining equipment, ensuring precise dimensions. The processes of cutting, drilling, and polishing ensure that each jig's structure meets requirements. The post-processing surface treatment enhances durability and aesthetic appeal. Precision Achievable: We can control the dimensions with precision up to ±0.02mm, ensuring that every Bakelite jig perfectly meets customer requirements and can handle high-precision machining needs. Dimensions and Shapes: The dimensions and shapes of Bakelite jigs can be customized based on customer needs. Common size ranges from 50mm to 500mm, and shapes include rectangular, round, U-shaped, etc. We can design different jig shapes based on customer process requirements. Burr Control: With high-precision CNC machining technology, we ensure that the edges of each jig are burr-free. We also use professional deburring processes to ensure smooth and safe edges. Surface Smoothness: The surface smoothness of the Bakelite jig meets the GB/T 2494-2017 standard, ensuring no scratches, even surface, and compliance with precision machining requirements. Material Thickness: The thickness of the Bakelite material can be customized according to customer needs, with a common thickness range from 2mm to 20mm. Thickness control accuracy is up to ±0.02mm. Error Control: Using precise CNC equipment, the error range is strictly controlled within ±0.02mm, ensuring the quality of each Bakelite jig meets the required standards.

Category:

Key Words:

Table Parameter

| Product Name | Bakelite Jig |

| Material | Bakelite (Phenolic Resin Board) |

| Size Range | 50mm - 500mm (Customizable) |

| Thickness Range | 2mm - 20mm |

| Shape | Rectangular, Round, U-shaped, etc. |

| Surface Treatment | Polishing, Grinding, etc. |

| Electrical Insulation | High electrical insulation performance, compliant with hardware industry standards |

| High-Temperature Resistance | Good high-temperature resistance, suitable for high-temperature environments |

| Strength | High strength, compliant with GB/T 5233 standards |

| Surface Smoothness | Compliant with GB/T 2494-2017 standard |

| Dimension Accuracy | ±0.02mm |

| Error Control | ±0.02mm |

| Application Fields | Electronics manufacturing, precision machining, electrical equipment, mold making, etc. |

Application Description

Bakelite jigs are widely used in the following fields:

Electronics Manufacturing: Used for assembly, testing, and debugging of electronic components.

Precision Machining: Used for clamping and positioning metal or plastic parts.

Electrical Equipment: Used for fixing, positioning, and testing electrical components.

Mold Making: Used for clamping and processing mold parts.

Laboratory Research: Used as fixtures and brackets in experimental equipment.

Aerospace: Used as high-strength connectors in aerospace equipment.

Questions and Answers

| 1.What aspects of the Bakelite jig can be customized? We can customize the dimensions, shapes, thickness, and surface treatment of the Bakelite jigs to meet specific application requirements. |

| 2.How is the product's error and dimensional precision controlled? We use advanced CNC machining equipment to ensure that the dimensional precision of the Bakelite jigs is controlled within ±0.02mm and maintain strict quality control processes to ensure product consistency. |

| 3.How do you ensure the electrical insulation of the Bakelite jigs? Bakelite material itself has excellent electrical insulation performance, compliant with hardware industry standards. We ensure the use of quality raw materials and process according to industry standards. |

| 4.How do you address surface scratch issues? Surface scratches usually arise from improper handling or improper storage. We use high-precision CNC equipment during production, along with polishing processes to ensure a smooth, even surface free of scratches. Additionally, we implement effective packaging measures to ensure that products are not damaged during transportation. |

| 5.How is the sample charged? Most of our products can be sampled for free, or we can provide similar products. Custom products or higher-cost samples may require a sample fee. Bulk orders will be charged based on unit price. |

| 6.Do you support customized processing? We can process according to customer-provided materials, technical requirements, and drawings. |

| 7.What is the delivery time? For mass production, the processing time is typically 5-15 days, depending on the quantity. In urgent cases, we can discuss ahead of time for quicker delivery. |

| 8.What are your payment methods? As customized products, full payment is required upfront. We support multiple payment methods including: 1.Letter of Credit (L/C) 2.Telegraphic Transfer (T/T) 3.PayPal (for small orders) 4.Western Union (for certain countries) 5.Alipay/WeChat Pay (for specific countries) We can choose the most suitable payment method according to your needs. |

| 9.What happens if the product is defective? Before mass production, we will send you samples for approval. After sample confirmation, mass production will begin. If any product is defective, please contact us with specific requirements. If the issue is caused by us, we will replace the product free of charge. |

Factory Description

We have a full set of etching production equipment and mature processing technology. We can manufacture products in any shape with mesh sizes as small as 0.1mm, according to your requirements.

Our Advantage

Factory Direct Shipping

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Experienced Design and Manufacturing Team

We work closely with customers from the design phase to help avoid potential product flaws, ensuring both the functionality and design meet expectations.

Excellent Supply Chain Management

We can quickly adjust production schedules to meet your urgent deadlines, whether it's for large bulk orders or smaller rush orders.

OEM & ODM Support

We offer the option to print your logo or other customizations.

Strict Quality Control

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Certificate

Related Products