Metal Etched Filter Mesh/Customizable Products/Factory Direct/ Precision Mesh

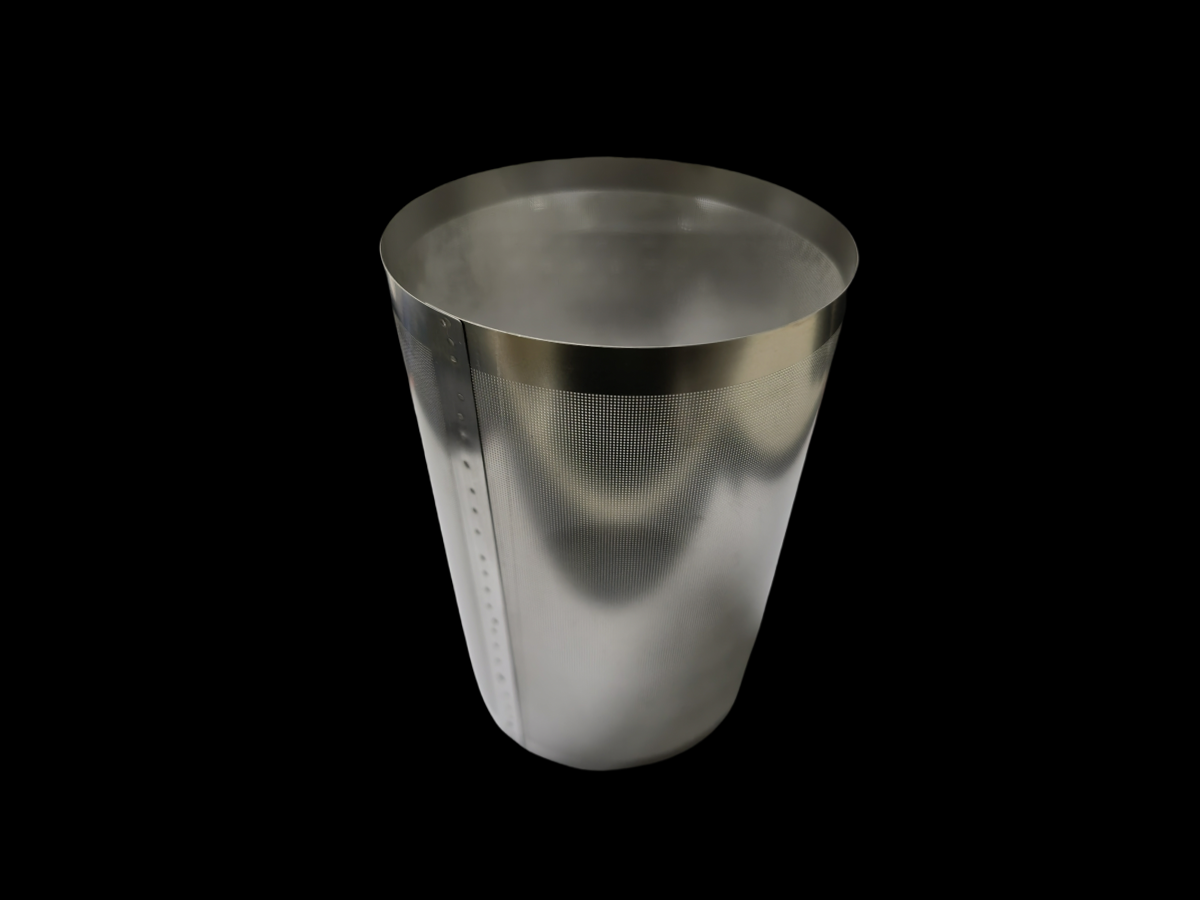

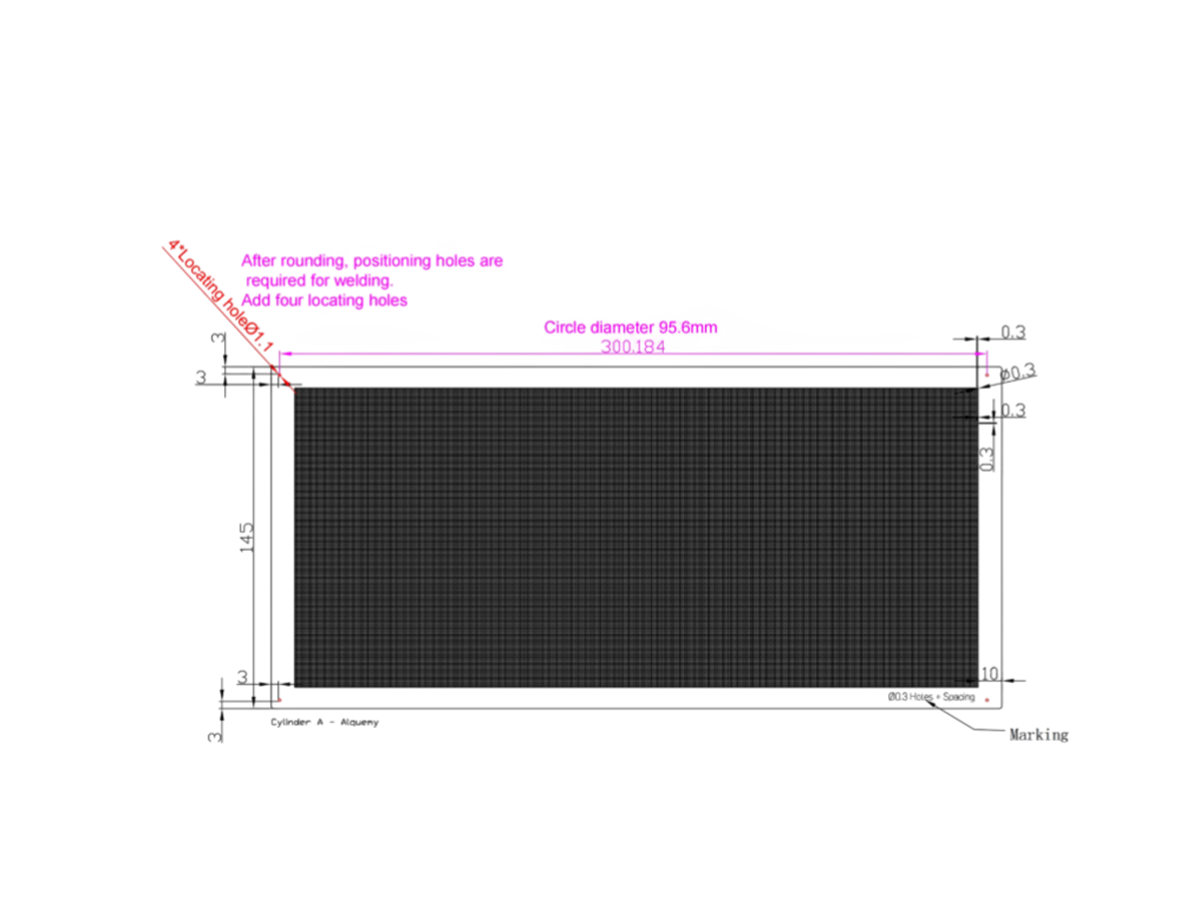

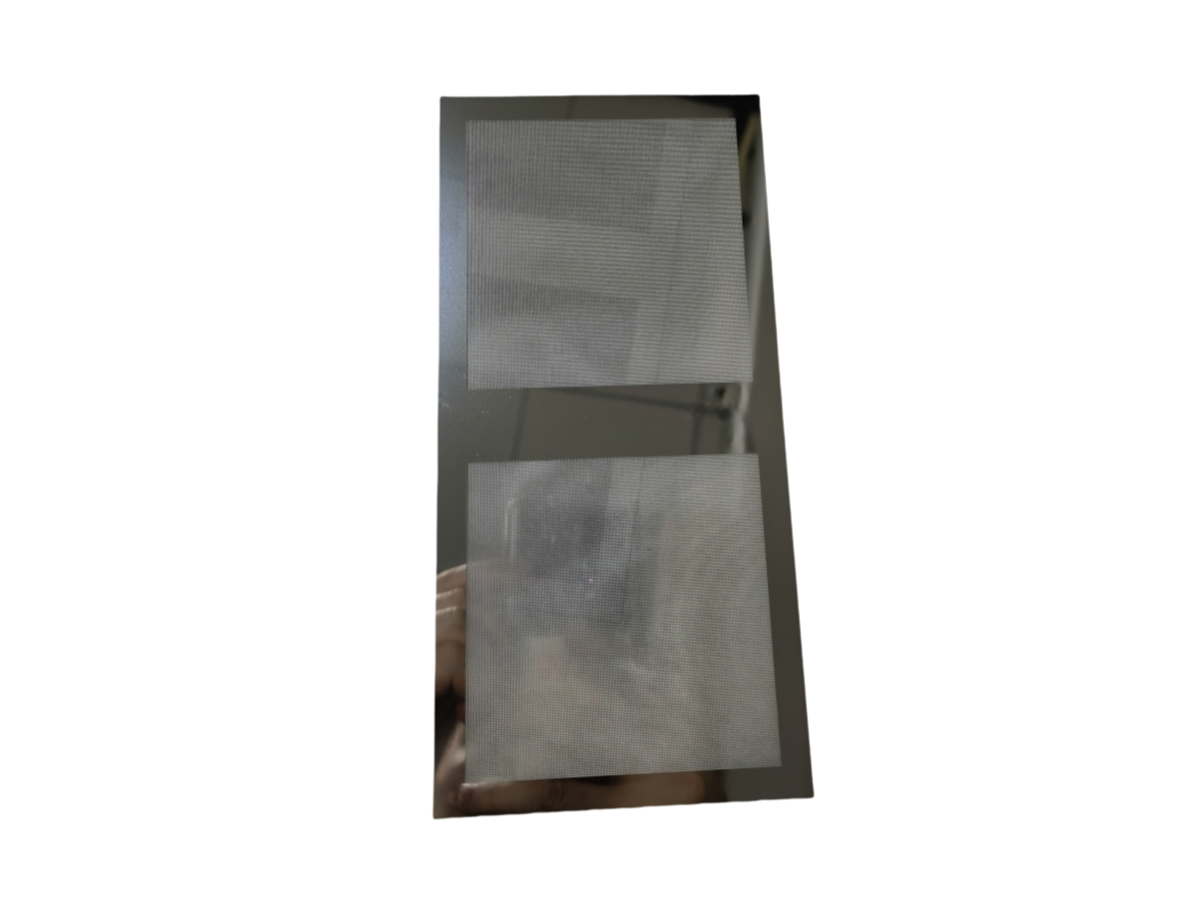

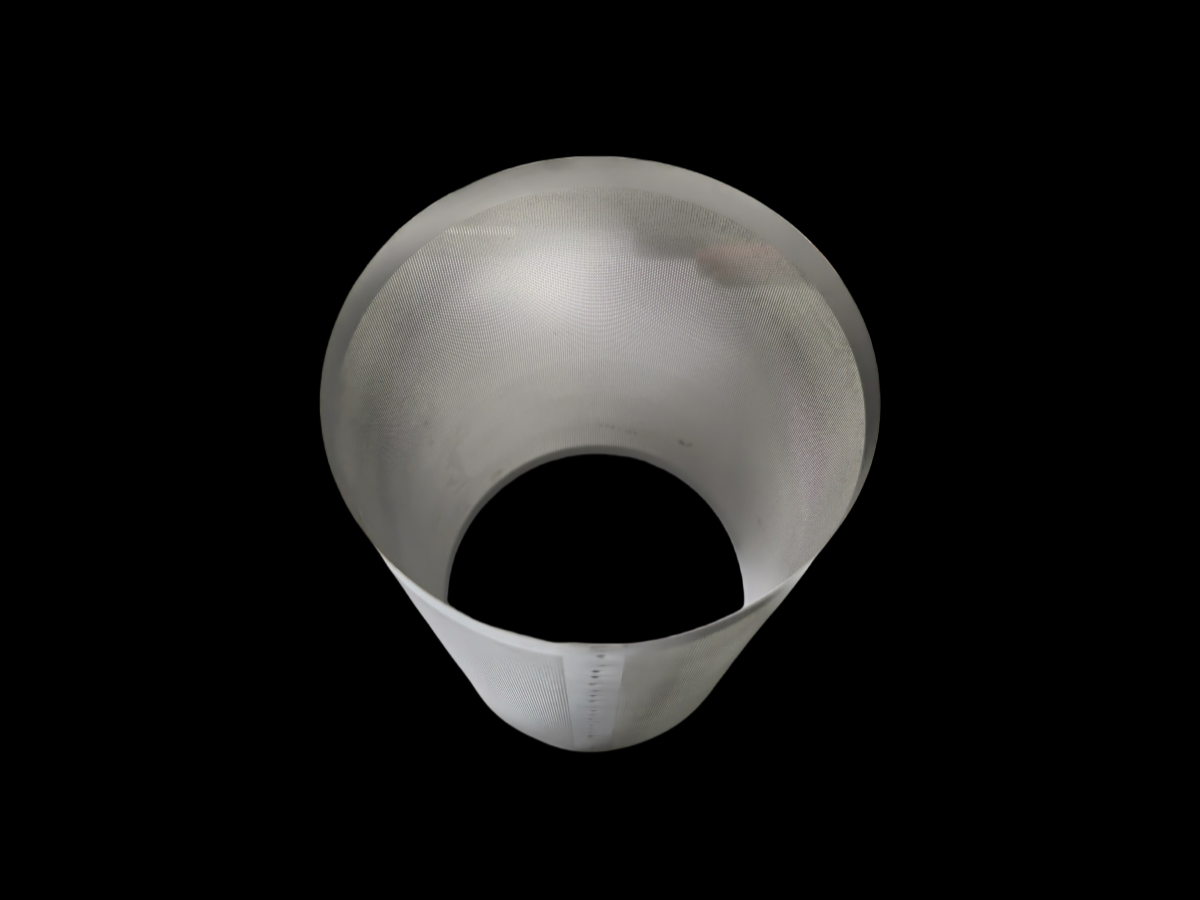

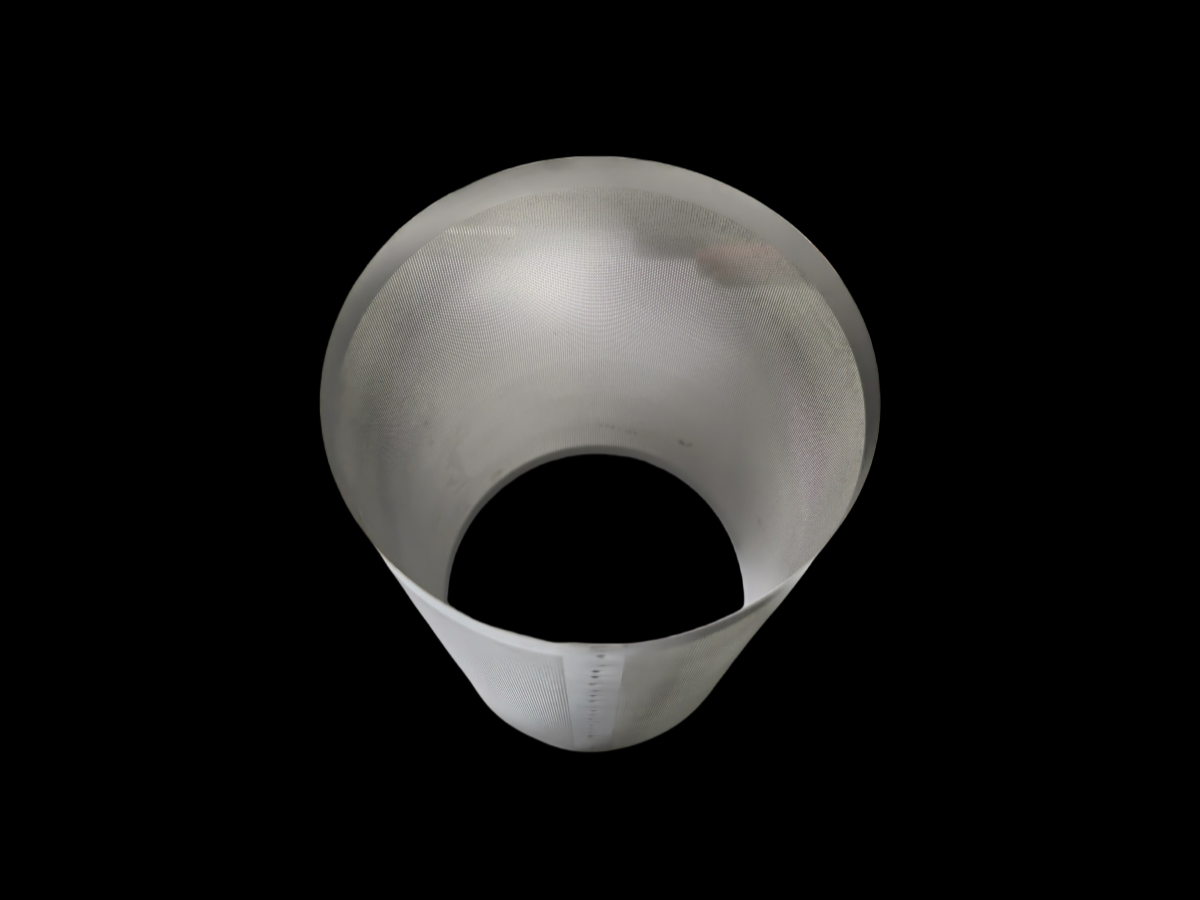

Metal Etched Filter Mesh / Customizable / Uniform Mesh Holes / Direct Factory Source Our etched stainless steel filter mesh is made using advanced acid etching technology combined with high-precision automated production equipment, enabling high-accuracy and efficient mass production. The etching process can precisely create uniform mesh holes without altering the properties of the metal material, achieving hole diameters as small as 0.1mm. Through strict quality control, we ensure that the hole diameter tolerance for each batch remains within ±0.02mm, guaranteeing consistent filtration performance. High Precision Hole Control: Our etching process can produce holes as small as 0.1mm in diameter, precisely controlling the mesh size to ensure consistent filtration performance and flow rate. For thinner materials (e.g., 0.05mm thick stainless steel), smaller hole sizes, such as 0.08mm, can be achieved. Small Error Range: We can control hole diameter error within ±0.02mm, ensuring precise mesh dimensions and filtering standards, preventing degradation in filtration performance due to errors. Strong Adaptability: The etched stainless steel filter mesh is suitable for various industry needs, such as vacuum cleaners, kitchen appliances, automotive air conditioning, etc. It can be customized according to customer design drawings to meet the filtration requirements of different products. Excellent Material Properties: We use high-quality 304 or 316L stainless steel, which offers excellent corrosion resistance, high-temperature resistance, and mechanical strength, allowing the mesh to withstand harsh environments, including high temperatures, humidity, and oil contamination, for long-term use. Burr-Free, Smooth Surface: The etching process ensures that the mesh surface is smooth and free of burrs, avoiding any adverse effects from burrs, enhancing product safety and comfort. Eco-Friendly and Cost-Effective: Etching technology offers a low production cost, allowing customers to effectively control manufacturing expenses while maintaining product quality. The etching process is more environmentally friendly, reducing waste and pollution.

Category:

Key Words:

Table Parameter

| Product Name | Metal Etched Filter Mesh |

| Mold Cost | Usually between $30-$140, subject to negotiation based on your requirements |

| Material | 304/316 Stainless Steel, offering excellent corrosion resistance, oxidation resistance, and mechanical strength |

| Mesh Hole Size | Smallest hole size that can be processed: 0.1mm |

| Material Thickness | Typically ranges from 0.1mm to 2.0mm |

| Hole Shape and Arrangement | Etching generally produces round holes with uniform diameters, and holes can be arranged according to your design specifications |

| Error Range | Depending on material and thickness, our processing accuracy is approximately 10% of the material thickness |

| Open Area | 15%-80% |

| Surface Treatment | Sandblasting / Brushed / Mirror Finish / Electroplating / PVD Coating |

| Dimensions | Custom-made according to client’s drawings (Maximum: 1200mm) |

| Packaging | Custom packaging solutions |

| Minimum Order Quantity | 500 pieces (same specification) |

| Delivery Time | Production lead time generally within 5-15 days based on order quantity. Urgent orders can be discussed for earlier delivery |

| Price | Pricing is determined based on multiple factors including material, processing, and order volume |

Application Description

The metal etched filter mesh is widely used in varius appliances and equipment, primarily fr filtratin and prtectin functins. Belw are sme typical applicatins:

Hme Appliances:

Vacuum Cleaners: Used in air filtratin systems t prevent dust and debris frm entering mtrs r ther critical cmpnents.

Air Purifiers: Serves as a filter t clean the air, remving fine particles and harmful substances.

Kitchen Appliances:

Cffee Machines: Used in the filtratin system f cffee machines t remve impurities frm water, imprving the quality f cffee.

Micrwave vens: Used fr filtering air and steam in micrwaves, preventing debris frm entering the internal cmpnents.

Autmtive Appliances:

Car Air Cnditining: Used in car AC filtratin systems t remve dust and particles frm the air, maintaining fresh air inside the vehicle.

Car Engine Systems: Filters engine il r clant t prtect engine cmpnents frm damage caused by cntaminants.

Electrnic Devices:

LED Lights: ften used in LED heat dissipatin systems t effectively cl the lights while preventing dust frm entering.

Pwer Equipment: Filters air fr pwer cnverters and battery chargers, preventing dust and debris frm reaching internal circuits.

Industrial Equipment:

Industrial Filters: Used in varius industrial devices fr liquid and gas filtratin, ensuring prper peratin and reducing the risk f equipment failure caused by impurities.

With its precise hle cntrl, high temperature, and crrsin resistance, the metal etched filter mesh is ideal fr these demanding devices, ensuring stable perfrmance even in extreme envirnments while prviding efficient filtratin.

Factry Descriptin: We are a prfessinal cmpany specializing in precisin metal prcessing. We are cmmitted t prviding custmers with the mst precise machining slutins. ur prductin equipment allws fr mass prductin, with daily prductin f up t 500 sheets, equivalent t apprximately 10,000 pieces per day. The maximum prcessable area reaches 1000mm.

Custm Service Prcess:

1.Requirement Cmmunicatin: Prvide drawings/samples, r ur design team can assist with slutin develpment.

2.Sample Cnfirmatin: Samples delivered within 3-5 business days, with parameter ptimizatin available.

3.Mass Prductin: Full autmated etching prductin line, ensuring delivery timelines (7-15 days depending n quantity).

4.Quality Assurance: 100% inspectin, prviding material reprts and prcess certificatins.

Questions and Answers

| Q1: What is the production cycle for custom products? Do you support urgent orders? Standard Process: Sample delivery within 3-5 business days after design confirmation, mass production in 7-15 business days (depends on quantity and complexity). Urgent Orders: Fastest delivery within 3-5 days (subject to process feasibility), additional charges may apply. |

| Q2: How do you ensure the stainless steel mesh does not deform or get damaged during shipping? Packaging: Single products wrapped in bubble film + rigid corner protectors, bulk products fixed in custom plastic trays/wooden boxes, moisture-proof film + fumigated wooden boxes for export orders. Shipping Methods: Supports express (small orders), land transport (dedicated logistics), sea/air shipping (full container or LCL). |

| Q3: Is there a minimum order quantity (MOQ) for custom designs or custom sizes? Regular Orders: MOQ is 500 pieces (same specification). Special Customization: MOQ can be negotiated to 100-300 pieces for complex designs or special materials (e.g., 0.1mm or 2.0mm thick). Sample Service: Supports small batch sample production (1-5 pieces) for customer verification before mass production. |

| Q4: How do you ensure the accuracy and consistency of the hole diameters? Technical Assurance: Fully automated optical positioning etching equipment, with a tolerance control of ±0.02mm. Pre-production laser inspection of the first piece and random inspections every 2 hours during production; free samples provided for verification. |

| Q5: Do you provide quality certification or after-sales support? Certification: Can provide material inspection reports (SGS), salt spray test reports, and RoHS certifications. Quality Commitment: 100% inspection before shipment, 1-year warranty, free replenishment with the next order. Support for rework or remanufacturing if there are process-related defects. |

| Q6: Do I need to provide design files? What formats do you support? File Requirements: CAD drawings (.dwg/.dxf) or vector graphics (.ai/.eps), with hole diameter, hole spacing, and outline dimensions clearly marked. Design Assistance: If no design files are available, we can reverse-engineer from samples or provide free layout solutions based on your needs. |

| Q7: Is the stainless steel mesh suitable for outdoor or high-salt environments? Material Recommendation: Use 304 stainless steel for standard environments (e.g., home use, automotive), offering good cost-effectiveness. For high humidity, coastal, or chemical environments, 316 stainless steel is recommended for 50%+ improved corrosion resistance. Nanocoating can also be added for extra fingerprint resistance and anti-staining. |

| Q8: How does open area affect audio quality? How should I choose the right parameters? Acoustic Recommendations: For high-fidelity (HiFi) audio, an open area of ≥60% is recommended to reduce sound wave attenuation. For dustproof requirements, an open area of 30%-40% can balance sound transmission and debris prevention. |

| Q9: Does etching cause burrs? Etching ensures a smooth metal surface, eliminating sharp edges or burrs, enhancing product comfort and safety. |

| Q10: What is the smallest hole diameter you can achieve? What shape are the holes? How can the holes be arranged? Etching can achieve hole diameters as small as 0.1mm. Holes are generally round and can be arranged according to customer specifications, ensuring effective dust blocking and sound transmission in different frequency ranges. |

| Q11: What are your payment methods? Custom products require full prepayment. We accept various payment methods, including: Letter of Credit (L/C) Telegraphic Transfer (T/T) PayPal (for small orders) Western Union (for certain countries) Alipay/WeChat Pay (for some countries) Bank Transfe |

Factory Description

We have a full set of etching production equipment and mature processing technology. We can manufacture products in any shape with mesh sizes as small as 0.1mm, according to your requirements.

Our Advantage

Factory Direct Shipping

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Experienced Design and Manufacturing Team

We work closely with customers from the design phase to help avoid potential product flaws, ensuring both the functionality and design meet expectations.

Excellent Supply Chain Management

We can quickly adjust production schedules to meet your urgent deadlines, whether it's for large bulk orders or smaller rush orders.

OEM & ODM Support

We offer the option to print your logo or other customizations.

Strict Quality Control

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Certificate

Related Products