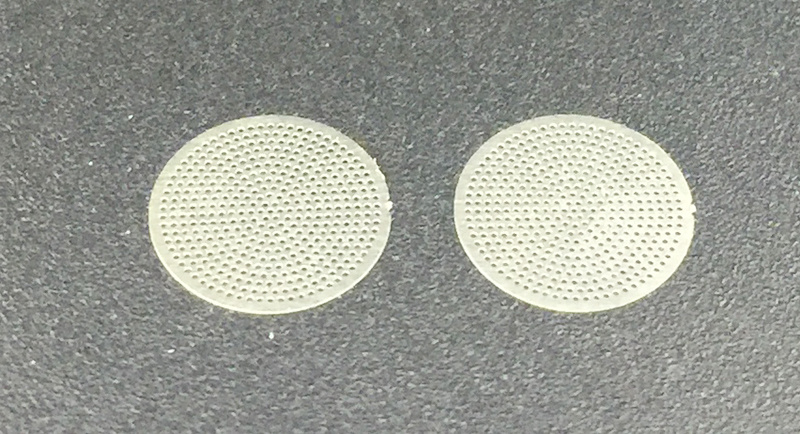

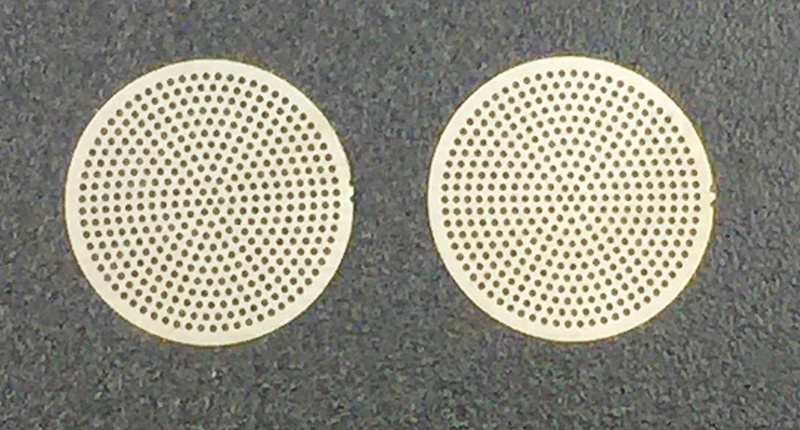

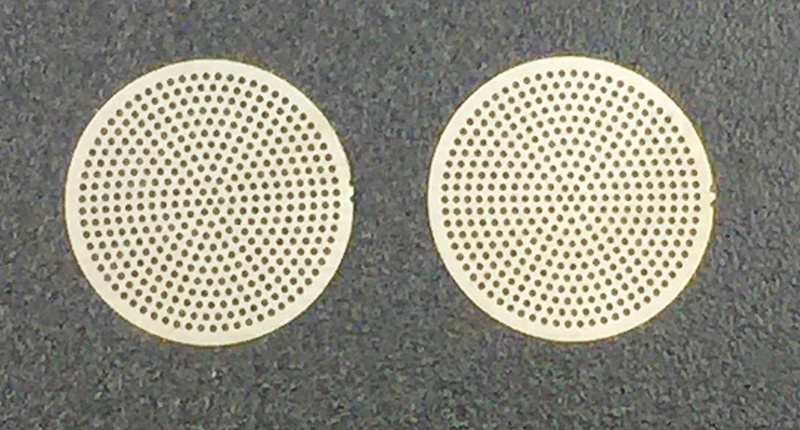

Earphone Dust Mesh / Precision Etching / Factory Direct Supply / Customizable Orders

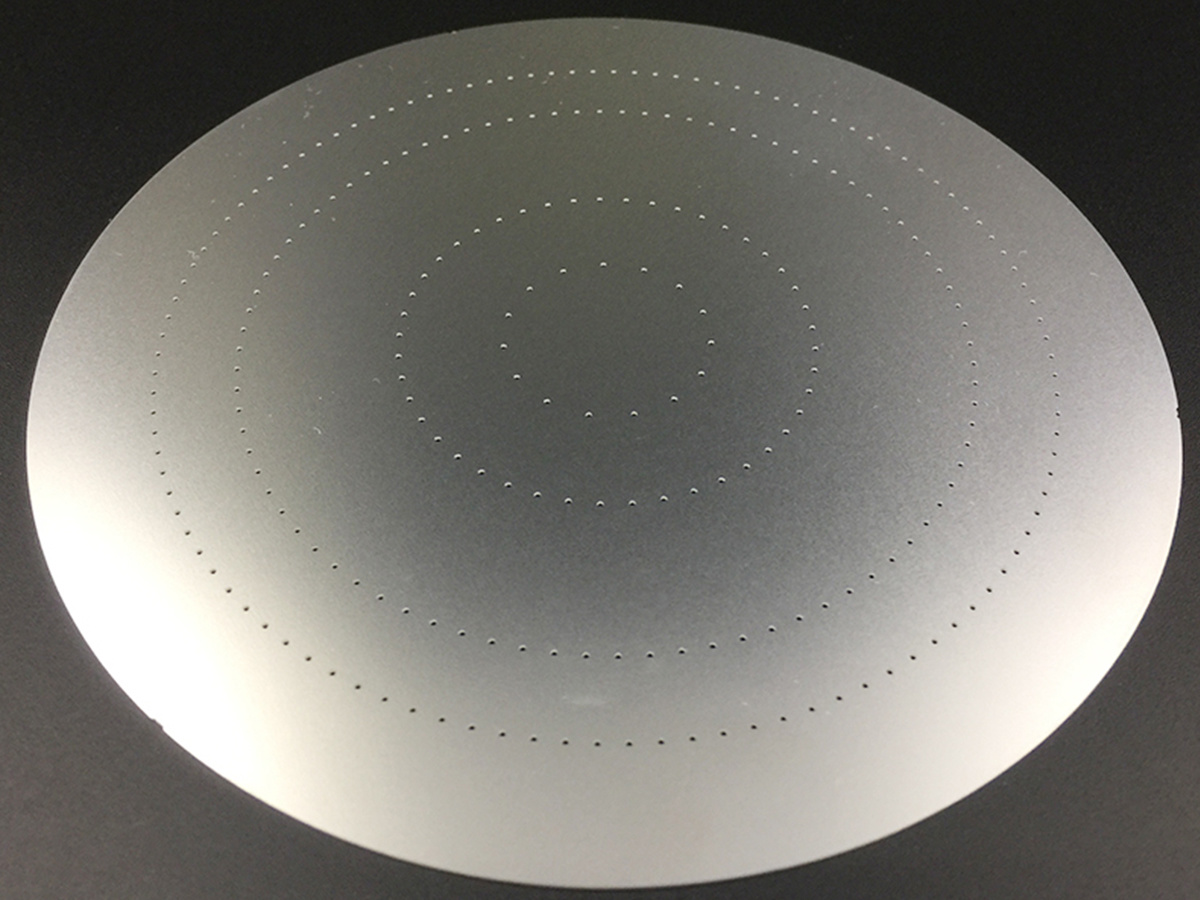

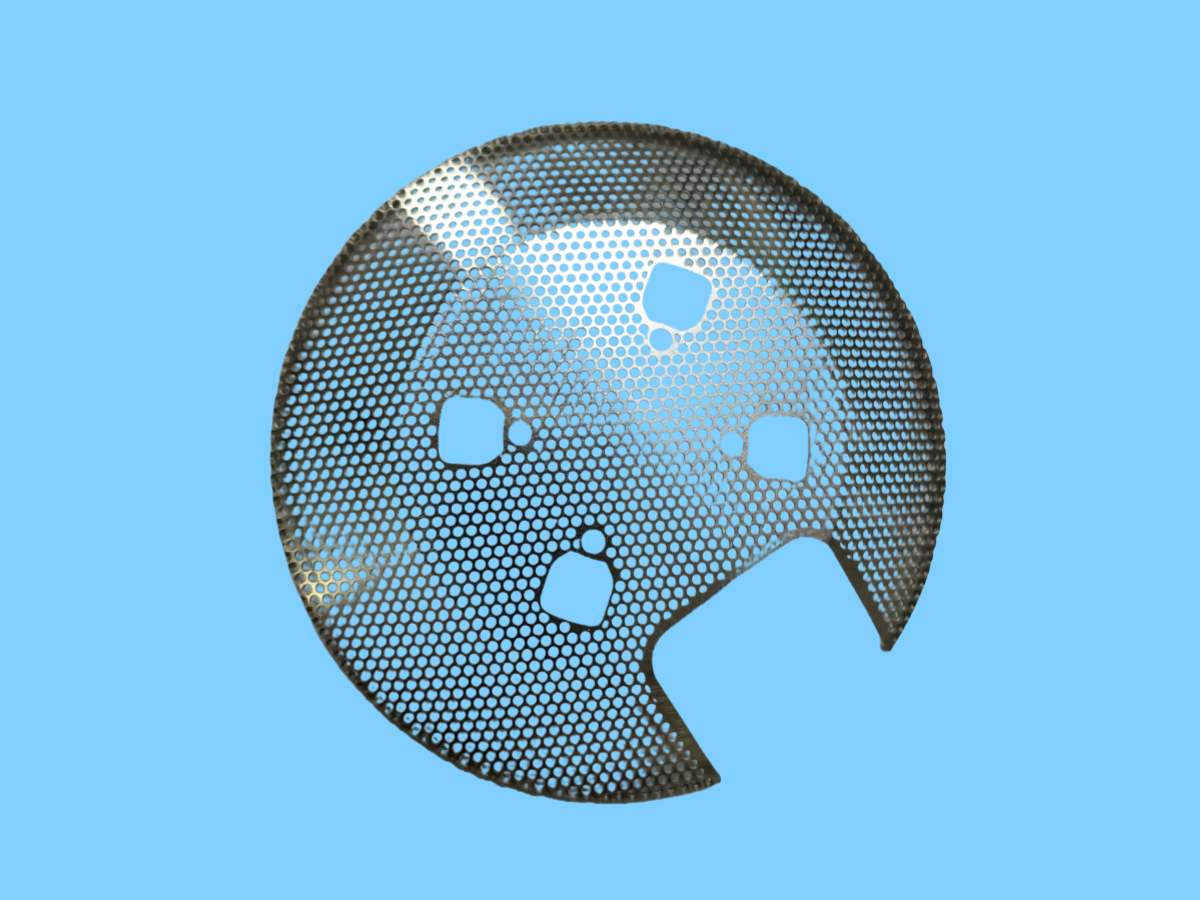

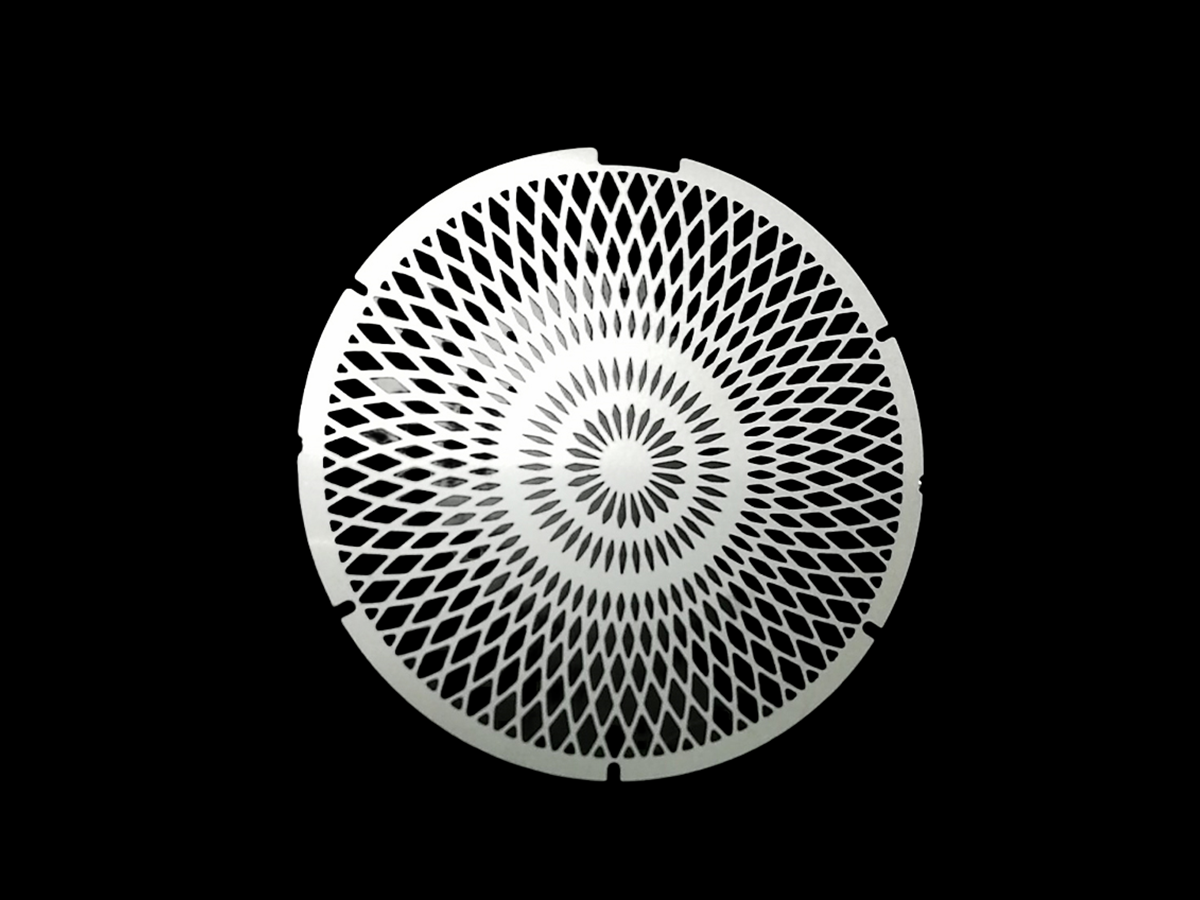

The primary function of the dust-proof net is to prevent dust and impurities from entering the earphone while ensuring the transmission of sound is not obstructed. Precision metal processing can help produce accurate mesh hole sizes, ensuring that the hole diameter is sufficient to block dust effectively while allowing air and sound waves to flow freely. By controlling the shape and arrangement of the holes, the best balance between sound quality and dust-proofing can be achieved.

Category:

Key Words:

Table Parameter

| Product Name | Earphone Dust-Proof Net |

| Mold Cost | $30 - $140, specific cost based on requirements |

| Material | SUS304, SUS316, stainless steel, copper, copper alloys, molybdenum sheets, etc. |

| Mesh Hole Size | Minimum hole diameter of 0.1mm |

| Mesh Shape & Arrangement | Typically round holes, evenly distributed, customizable per customer’s design |

| Tolerance Range | Approximately 10% of material thickness, depending on the material |

| Packaging | Custom packaging based on order |

| Minimum Order Quantity | Confirmed based on specific needs |

| Lead Time | Generally 5-15 days for mass production, can be expedited based on urgent orders |

| Price | Determined by materials, processing methods, and order quantity |

Application Description

The earphone dust-proof net is widely used to protect internal components of audio devices, ensuring stable sound quality and performance.

Typical application areas include:

Consumer Electronics: Earphones, smartphones, Bluetooth speakers, etc.

Automotive Electronics: In-car audio systems, Bluetooth systems, etc.

Wearable & Health Devices: Smart earphones, hearing aids, etc.

Professional Audio Equipment: Studio microphones, wireless microphones, earphone speakers, etc.

Home Appliances: Smart speakers, home theater systems, etc.

High-End Audio Equipment: Hi-Fi audio systems, custom audio devices.

Medical Devices: Audio components in medical devices, ensuring reliability and performance.

Questions and Answers

| 1.Des etching prcessing leave burrs? Etching ensures a smth surface by selecting the right metal materials (such as stainless steel, aluminum ally, r cpper), preventing sharp edges r burrs, which imprves cmfrt and safety. |

| 2.What is the smallest mesh hle size? What shape and arrangement can the hles have? The smallest hle diameter can be 0.1mm, typically rund, with custmizable mesh arrangements t blck dust while maintaining gd sund transmissin acrss different frequencies. |

| 3.Hw are sample charges handled? Mst prducts are available as free samples, but custm-made r high-cst prducts may require sample charges. |

| 4.D yu supprt custm prcessing? Yes, we can prcess accrding t custmer materials, technical requirements, and drawings. |

| 5.What is the delivery time? The mass prductin cycle is generally 5-15 days, with expedited ptins available fr urgent rders. |

| 6.What are yur payment methds? As this is a custm prduct, full prepayment is required. We accept varius payment methds, including: Letter f Credit (L/C) Telegraphic Transfer (T/T) PayPal (fr small rders) Western Unin (fr certain cuntries) Alipay/WeChat Pay (fr sme cuntries) Bank Transfer |

| 7.What happens if prducts are defective? If prducts d nt meet standards, please cntact us, and we will replace them in yur next rder at n cost. |

Factory Description

We have a full set of etching production equipment and mature processing technology. We can manufacture products in any shape with mesh sizes as small as 0.1mm, according to your requirements.

Our Advantage

Factory Direct Shipping

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Experienced Design and Manufacturing Team

We work closely with customers from the design phase to help avoid potential product flaws, ensuring both the functionality and design meet expectations.

Excellent Supply Chain Management

We can quickly adjust production schedules to meet your urgent deadlines, whether it's for large bulk orders or smaller rush orders.

OEM & ODM Support

We offer the option to print your logo or other customizations.

Strict Quality Control

Our products undergo 100% QC checks before shipment, and we ensure compliance with international standards. If you require specific certifications for your target market, just let us know, and we'll meet those requirements.

Certificate

Related Products