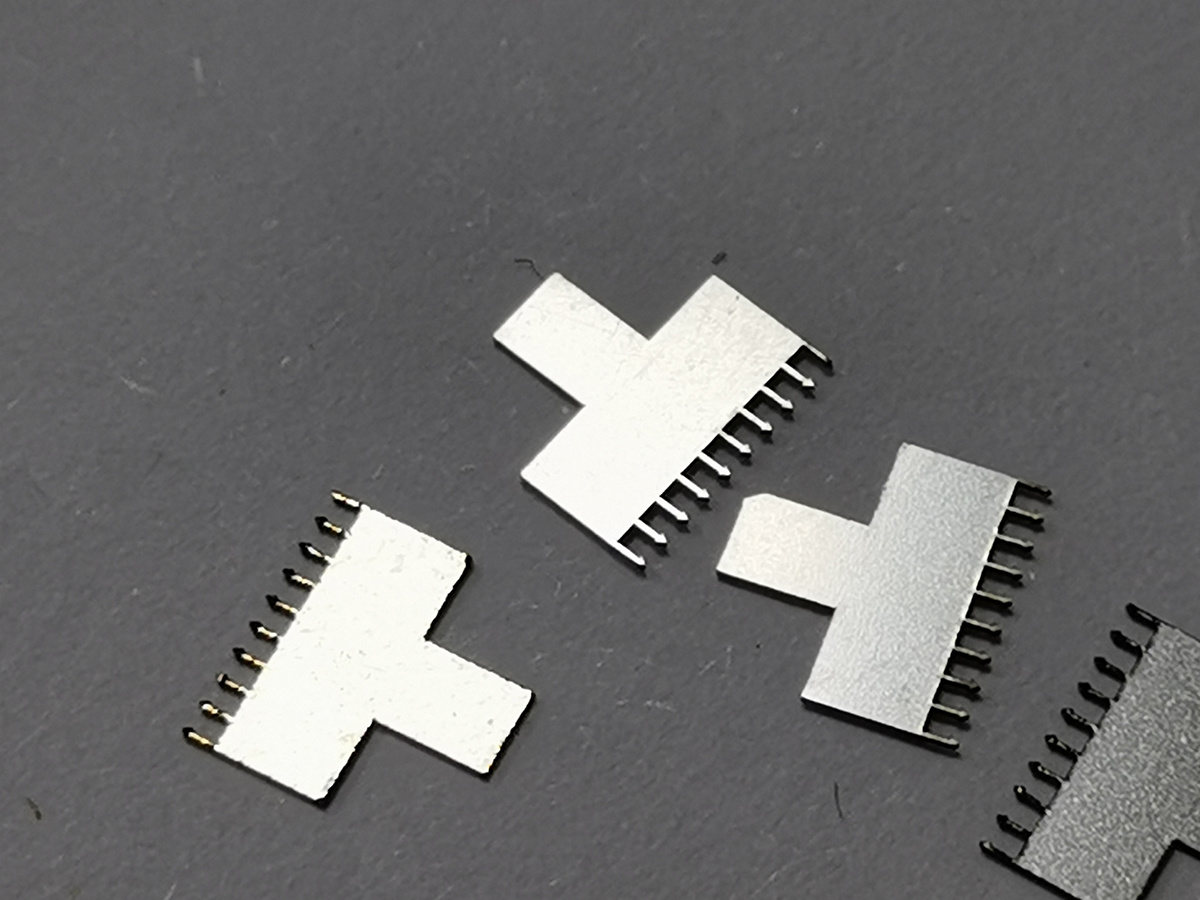

Stainless steel etched microneedle tips represent a cutting-edge development in material science and engineering. These tiny needles, which are typically used in medical and cosmetic applications, have garnered attention for their unique properties and potential benefits across various sectors, including metallurgy and energy.

One of the most notable features of stainless steel etched microneedle tips is their precision. The etching process allows for the creation of microneedles with extremely fine dimensions, which can enhance their efficacy in applications such as drug delivery, transdermal patches, and even cosmetic treatments. By utilizing stainless steel, manufacturers ensure durability and resistance to corrosion, which is crucial in maintaining the integrity of these devices over time.

In the context of metallurgy, stainless steel etched microneedle tips can be utilized to improve material properties and surface finishes. For example, they can be employed in processes such as micro-electro-discharge machining (EDM), where precise surface modifications are required. The ability to create micro-scale features on stainless steel surfaces can lead to enhanced performance in a range of applications, from automotive to aerospace components.

Moreover, the energy sector can benefit significantly from the implementation of these microneedle tips. They can be used in sensors that monitor various parameters within energy systems, contributing to more efficient energy management. The advanced sensitivity and precision of etched microneedle tips enable the development of sensors that can operate effectively in extreme conditions, further promoting innovation in renewable energy technologies.

Another advantage of stainless steel etched microneedle tips is their biocompatibility. Since they are made from stainless steel, they are less likely to cause adverse reactions when used in medical applications. This biocompatibility makes them ideal for use in drug delivery systems, where minimizing inflammation and promoting optimal drug absorption are key factors.

In conclusion, stainless steel etched microneedle tips are revolutionizing various fields, particularly in metallurgy and energy. Their precision, durability, and biocompatibility make them valuable tools for enhancing product performance and efficiency. As industries continue to explore innovative applications for these microneedles, the potential for new breakthroughs remains vast. Understanding the benefits and applications of stainless steel etched microneedle tips can empower professionals in these sectors to leverage this technology for improved outcomes.

One of the most notable features of stainless steel etched microneedle tips is their precision. The etching process allows for the creation of microneedles with extremely fine dimensions, which can enhance their efficacy in applications such as drug delivery, transdermal patches, and even cosmetic treatments. By utilizing stainless steel, manufacturers ensure durability and resistance to corrosion, which is crucial in maintaining the integrity of these devices over time.

In the context of metallurgy, stainless steel etched microneedle tips can be utilized to improve material properties and surface finishes. For example, they can be employed in processes such as micro-electro-discharge machining (EDM), where precise surface modifications are required. The ability to create micro-scale features on stainless steel surfaces can lead to enhanced performance in a range of applications, from automotive to aerospace components.

Moreover, the energy sector can benefit significantly from the implementation of these microneedle tips. They can be used in sensors that monitor various parameters within energy systems, contributing to more efficient energy management. The advanced sensitivity and precision of etched microneedle tips enable the development of sensors that can operate effectively in extreme conditions, further promoting innovation in renewable energy technologies.

Another advantage of stainless steel etched microneedle tips is their biocompatibility. Since they are made from stainless steel, they are less likely to cause adverse reactions when used in medical applications. This biocompatibility makes them ideal for use in drug delivery systems, where minimizing inflammation and promoting optimal drug absorption are key factors.

In conclusion, stainless steel etched microneedle tips are revolutionizing various fields, particularly in metallurgy and energy. Their precision, durability, and biocompatibility make them valuable tools for enhancing product performance and efficiency. As industries continue to explore innovative applications for these microneedles, the potential for new breakthroughs remains vast. Understanding the benefits and applications of stainless steel etched microneedle tips can empower professionals in these sectors to leverage this technology for improved outcomes.

Related News