The Role of Stainless Steel in Ensuring Quality Microneedle Tips

Table of Contents

1. Introduction to Microneedle Technology

2. Understanding the Composition of Stainless Steel

3. Benefits of Stainless Steel in Microneedle Tips

3.1 Durability and Strength

3.2 Precision and Sharpness

3.3 Biocompatibility and Safety

4. The Manufacturing Process of Stainless Steel Microneedle Tips

4.1 Material Selection

4.2 Fabrication Techniques

4.3 Quality Control Measures

5. Applications of Stainless Steel Microneedle Tips in Medicine

6. Comparing Stainless Steel to Other Materials in Microneedle Design

7. Future Trends in Microneedle Technology

8. Conclusion: Emphasizing the Importance of Stainless Steel in Microneedle Tips

9. FAQs

1. Introduction to Microneedle Technology

Microneedle technology has revolutionized the field of medical needle applications, offering pain-free delivery of medications and vaccines. These tiny needles, often just a fraction of a millimeter in length, provide a minimally invasive method for penetrating the skin. Their design allows for efficient drug delivery, making them an invaluable tool in various treatments, from vaccinations to cosmetic applications.

2. Understanding the Composition of Stainless Steel

Stainless steel is an alloy primarily composed of iron, chromium, and nickel. The presence of chromium is what gives stainless steel its corrosion-resistant properties, making it a preferred choice in medical applications. The alloy's composition can vary, leading to different grades that offer specific properties suitable for various uses. For microneedles, the choice of stainless steel grade is critical to achieving the desired balance of strength, corrosion resistance, and biocompatibility.

3. Benefits of Stainless Steel in Microneedle Tips

The choice of material directly impacts the performance and safety of microneedle tips. Here are some key benefits of using stainless steel:

3.1 Durability and Strength

Stainless steel is known for its exceptional strength and durability, making it resistant to bending or breaking during insertion. This durability ensures that microneedles maintain their integrity, even when used in challenging environments, resulting in consistent performance and reduced risk of malfunction.

3.2 Precision and Sharpness

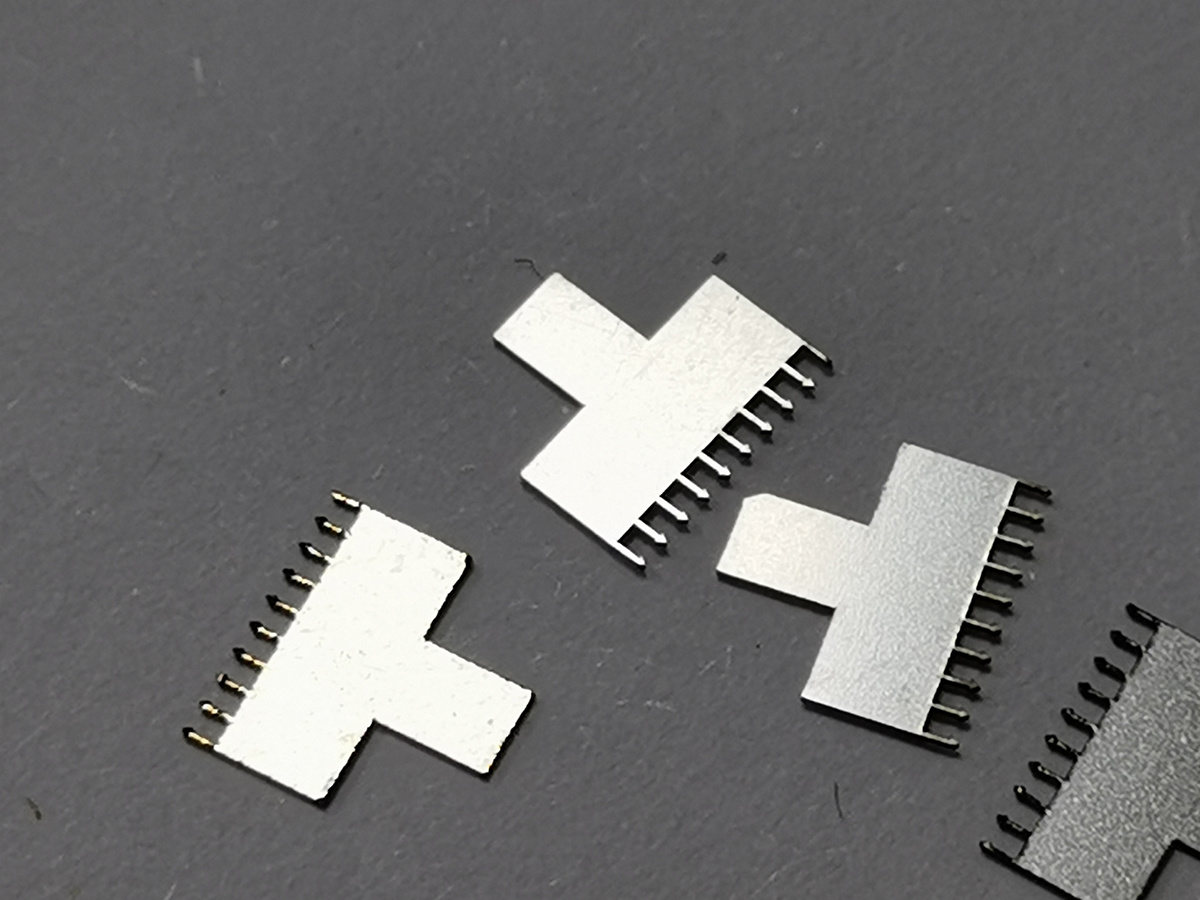

The manufacturing process of stainless steel microneedle tips allows for high precision in their design, ensuring that each needle is sharp and finely pointed. This sharpness is crucial for a painless experience during administration and ensures effective penetration of the skin, facilitating optimal drug delivery.

3.3 Biocompatibility and Safety

Stainless steel is highly biocompatible, meaning it can safely interact with the human body without causing adverse reactions. This property is vital in medical applications, where patient safety is paramount. Using stainless steel microneedles minimizes the risk of infection and allergic reactions, making them a safe choice for healthcare providers.

4. The Manufacturing Process of Stainless Steel Microneedle Tips

The production of stainless steel microneedle tips involves several key steps that ensure high quality and performance.

4.1 Material Selection

Choosing the right grade of stainless steel is the first step in the manufacturing process. Manufacturers must consider the mechanical properties, corrosion resistance, and biocompatibility of various stainless steel grades to ensure optimal performance.

4.2 Fabrication Techniques

Microneedle tips can be fabricated using various techniques, such as laser cutting, molding, and etching. Each method has its advantages, but laser cutting is often favored for its precision and ability to create sharp, uniform tips.

4.3 Quality Control Measures

Quality control is essential in the production of microneedles. Manufacturers implement rigorous testing standards to ensure that each batch of microneedles meets safety and performance criteria. This includes testing for sharpness, strength, and biocompatibility.

5. Applications of Stainless Steel Microneedle Tips in Medicine

Stainless steel microneedle tips find numerous applications across various fields in medicine, including:

- **Vaccination**: Facilitating painless delivery of vaccines with reduced patient anxiety.

- **Drug Delivery**: Ensuring accurate and efficient delivery of medications for conditions like diabetes.

- **Cosmetic Procedures**: Utilizing microneedles for skincare treatments that promote collagen production and improve skin texture.

6. Comparing Stainless Steel to Other Materials in Microneedle Design

Although several materials are used in microneedle design, stainless steel stands out for its superior properties. Other materials, such as polymer and silicon, may be less durable or biocompatible. Here, we compare stainless steel to these alternatives:

- **Polymers**: While flexible, they may lack the strength and precision needed for effective drug delivery.

- **Silicon**: This can be brittle and prone to breakage, compromising safety and performance.

Ultimately, stainless steel remains the gold standard due to its strength, precision, and safety profile.

7. Future Trends in Microneedle Technology

The future of microneedle technology is filled with exciting possibilities. Advances in materials science may lead to the development of even more refined stainless steel alloys that enhance the performance of microneedle tips. Researchers are also exploring the integration of microneedles with digital technologies, such as smart delivery systems that monitor dosage and patient compliance.

8. Conclusion: Emphasizing the Importance of Stainless Steel in Microneedle Tips

In summary, stainless steel plays a pivotal role in ensuring the quality and effectiveness of microneedle tips. Its durability, precision, and biocompatibility position it as the material of choice for medical applications. As microneedle technology continues to evolve, stainless steel will likely remain at the forefront, driving innovations in pain-free drug delivery and enhancing patient care.

9. FAQs

Q1: Why is stainless steel preferred for microneedle tips?

A1: Stainless steel is preferred due to its durability, sharpness, and biocompatibility, ensuring safe and effective drug delivery.

Q2: How are stainless steel microneedles manufactured?

A2: They are manufactured through processes like laser cutting, molding, and etching, followed by rigorous quality control.

Q3: What are the main applications of microneedles?

A3: Microneedles are primarily used in vaccinations, drug delivery, and cosmetic procedures.

Q4: Are there alternatives to stainless steel in microneedle design?

A4: Yes, alternatives include polymers and silicon, but stainless steel offers superior strength and precision.

Q5: What future advancements can we expect in microneedle technology?

A5: Future advancements may include new stainless steel alloys and smart delivery systems that enhance usability and patient monitoring.

By focusing on the unique benefits and critical role of stainless steel in the production of microneedle tips, we provide a comprehensive understanding of why this material is essential for quality and safety in medical applications.

Related News