Understanding Laminated Shims

When it comes to precision in construction and manufacturing, the little things often make a big difference. Enter laminated shims. These nifty pieces of material may seem minor, but they pack a punch when it comes to stability and alignment.

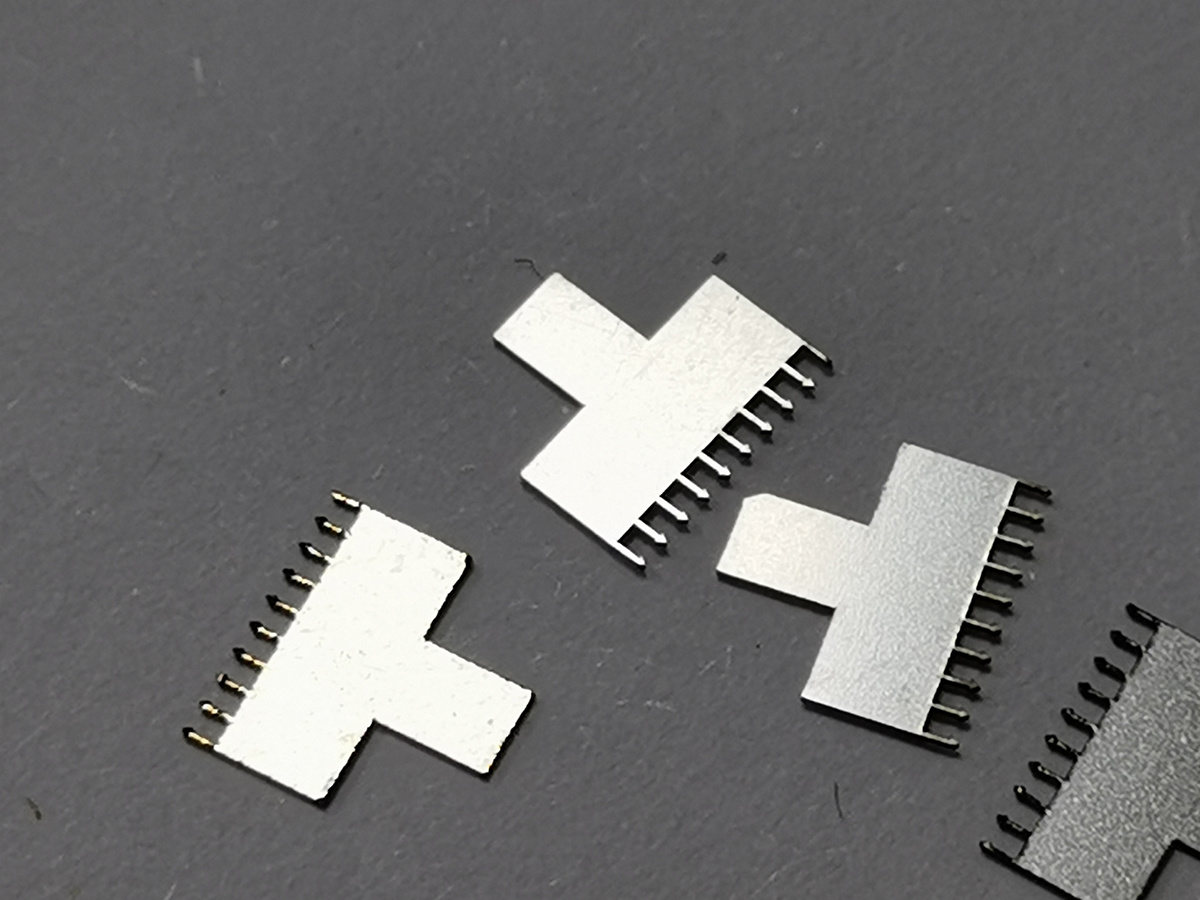

What Are Laminated Shims?

So, what exactly are laminated shims? Think of them as the unsung heroes of engineering! Made from several layers of material, these shims provide superior strength and flexibility. Whether you’re leveling a machine or adjusting the height of a surface, laminated shims are there to save the day.

Why Use Laminated Shims?

Now, you might be wondering, why should I bother with laminated shims? Well, let’s break it down. First off, they’re incredibly versatile. You can find them in various industries, from construction to aerospace, and they come in different sizes and thicknesses to suit your needs. Plus, they’re durable! Laminated shims can withstand harsh conditions, making them ideal for both indoor and outdoor applications.

Easy to Use

Using laminated shims is a breeze. Just slide them into place, and voila! You’ve got a perfectly aligned surface. It’s as easy as pie. And let’s be honest, who doesn’t appreciate a hassle-free solution?

Cost-Effective Solution

In today’s fast-paced world, keeping costs down is essential. Laminated shims are not only affordable but can also save you money in the long run. By providing precise alignment, they reduce wear and tear on machinery, minimizing maintenance costs. Talk about a win-win!

Applications of Laminated Shims

The applications for laminated shims are endless. Here are just a few ways they’re being used:

- Construction: Laminated shims are crucial for leveling beams, doors, and windows.

- Machinery: They help align components in manufacturing equipment, ensuring smooth operation.

- Aerospace: In aviation, precision is key. Laminated shims assist in aligning aircraft components for safety and efficiency.

- Automotive: They’re used to adjust the height and alignment of various car parts.

Customization at Its Best

What’s cool about laminated shims is that they can be customized. Need a specific size or thickness? No problem! Many manufacturers offer tailored solutions to meet your exact requirements. This level of customization is a game-changer in industries where precision is non-negotiable.

Choosing the Right Laminated Shim

So, how do you pick the right laminated shim? It all boils down to the application. Consider the weight load, environmental factors, and the specific alignment needs. It might feel a bit overwhelming, but trust me, once you get the hang of it, you’ll be shim-savvy in no time!

Consulting Experts

And hey, if you’re ever in doubt, don’t hesitate to consult with industry experts. They can offer invaluable insights and help you make the best choice for your project.

Final Thoughts

In conclusion, laminated shims are more than just a tool; they’re a vital part of achieving precision in various industries. Their versatility, durability, and cost-effectiveness make them a go-to solution for professionals everywhere. So, the next time you’re working on a project, remember the power of laminated shims. They just might be the secret ingredient you’ve been missing!

Related News