How Peelable Gaskets Enhance Equipment Performance

Table of Contents

- 1. Introduction to Peelable Gaskets

- 2. What Are Peelable Gaskets?

- 3. Benefits of Peelable Gaskets in Industrial Applications

- 4. Applications of Peelable Gaskets in Various Industries

- 5. How Peelable Gaskets Work: A Technical Overview

- 6. Choosing the Right Peelable Gasket for Your Needs

- 7. Common Misconceptions About Peelable Gaskets

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Peelable Gaskets

In the world of industrial equipment, the performance and reliability of machinery are paramount. Often overlooked, gaskets play a crucial role in ensuring that equipment operates smoothly and efficiently. Among the various types of gaskets available, **peelable gaskets** are gaining increasing recognition for their significant benefits. This article delves deep into how peelable gaskets enhance equipment performance, thereby improving operational efficiency and reducing maintenance costs.

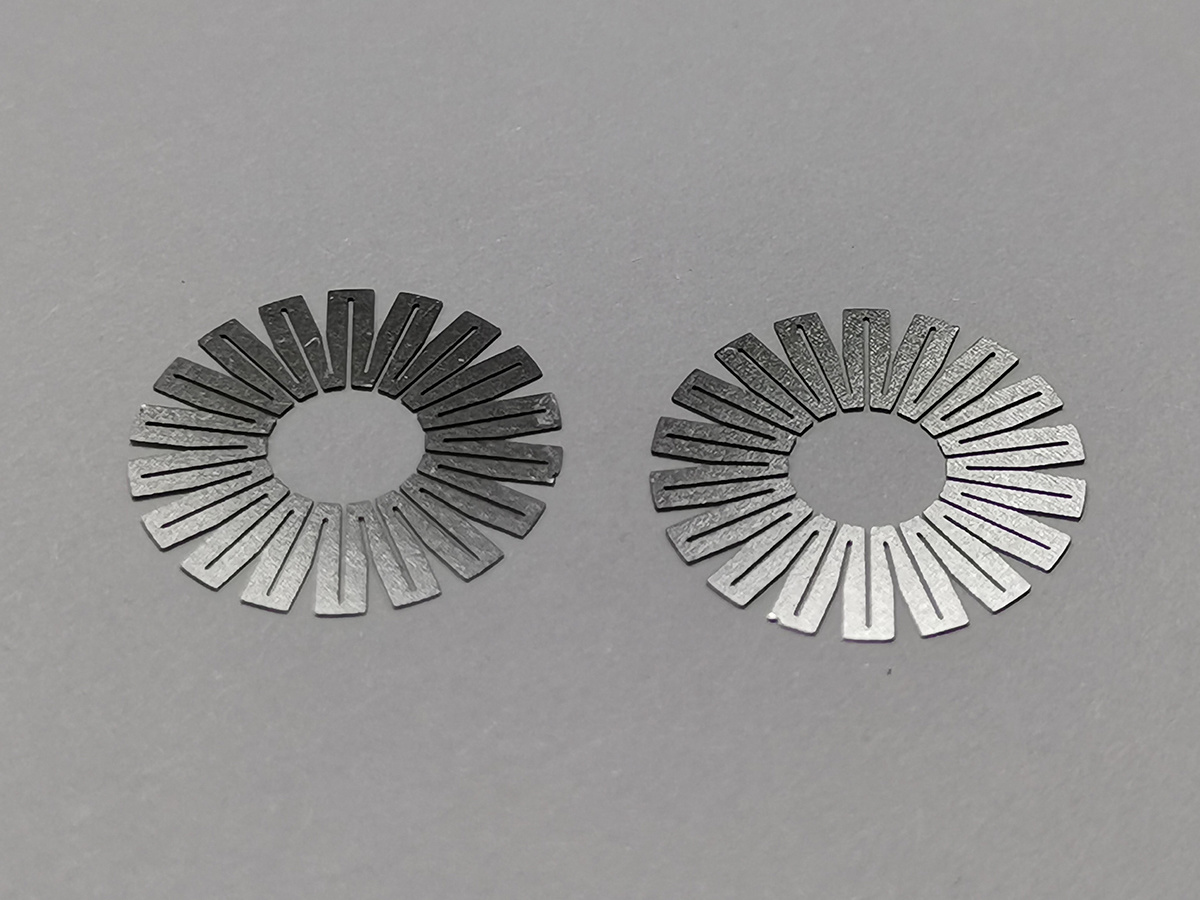

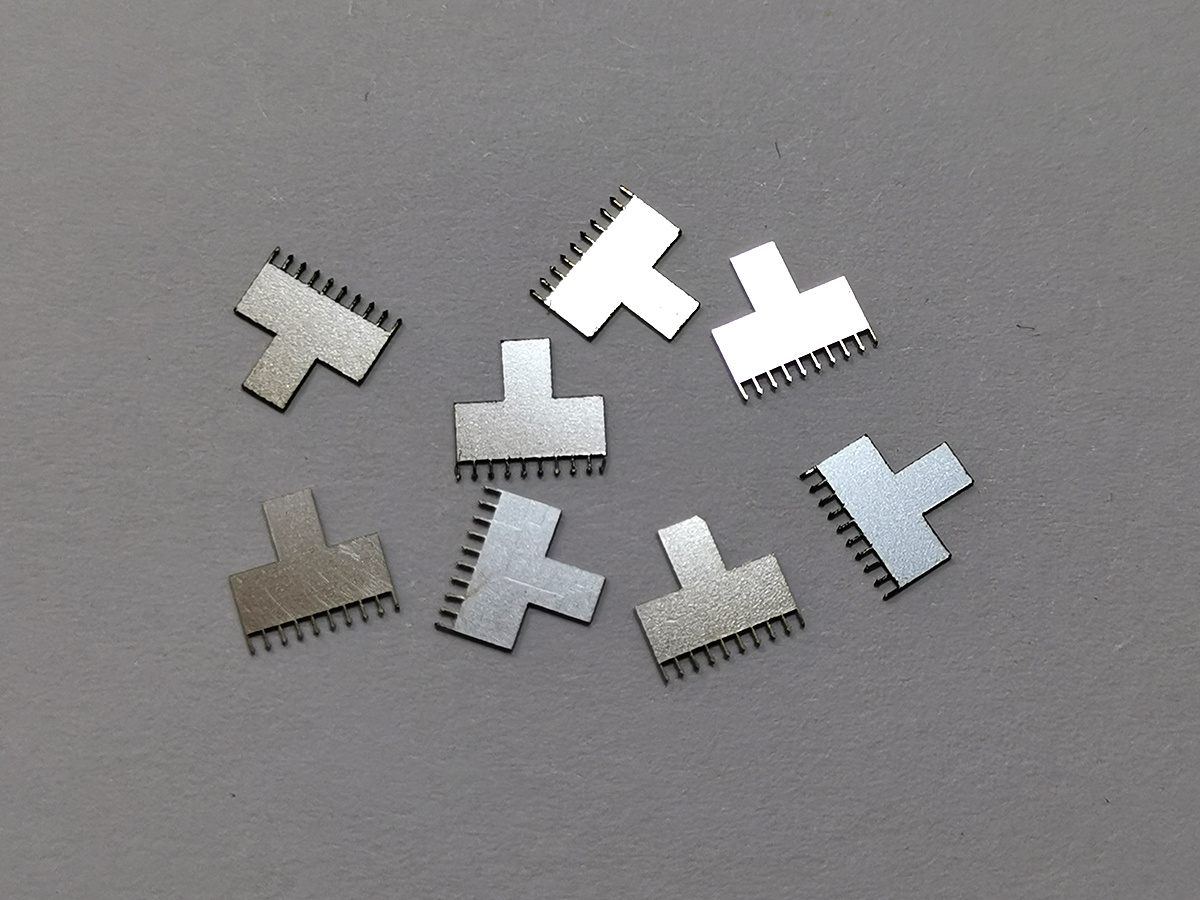

2. What Are Peelable Gaskets?

Peelable gaskets are specialized sealing elements designed to be easily removed and replaced. They consist of a thin layer of material that can be applied to the sealing surface of equipment, providing an effective barrier against leaks, contaminants, and other undesirable elements. Their innovative design allows for quick installation and removal, making them an ideal choice for various industrial applications.

3. Benefits of Peelable Gaskets in Industrial Applications

Peelable gaskets are not just a passing trend; they offer a multitude of advantages that significantly enhance equipment performance.

3.1 Enhanced Sealing Performance

One of the primary benefits of peelable gaskets is their exceptional sealing capabilities. Made from high-quality materials, these gaskets can withstand a wide range of temperatures and pressures, ensuring a tight seal that prevents leaks. This is particularly crucial in high-stakes industries where even minor leaks can lead to costly downtimes and safety hazards.

3.2 Cost-Effectiveness

Cost-savings are a critical consideration for any business. Peelable gaskets offer a cost-effective solution by reducing the need for frequent replacements and maintenance. Since they are designed for easy installation and removal, they save time and labor costs, allowing businesses to allocate their resources more efficiently.

3.3 Time Efficiency and Ease of Use

The ease of use associated with peelable gaskets cannot be overstated. Their intuitive design and straightforward application process mean that technicians can install or replace them without specialized training or tools. This time efficiency translates to quicker turnaround times for maintenance schedules, minimizing disruptions to operations.

4. Applications of Peelable Gaskets in Various Industries

Peelable gaskets are versatile components that find applications in numerous industries.

4.1 Manufacturing Industry

In the manufacturing sector, peelable gaskets are indispensable for machinery that demands high precision. They ensure that components fit perfectly together, reducing wear and tear on parts while enhancing overall efficiency.

4.2 Automotive Applications

The automotive industry relies heavily on peelable gaskets to maintain the integrity of various systems, including engines and exhausts. Their heat and pressure resistance make them ideal for automotive applications, where performance and safety are non-negotiable.

4.3 Food Processing Industry

In the food processing industry, hygiene is paramount. Peelable gaskets help maintain sanitary conditions by preventing leaks and contamination, making them an essential component in food-grade equipment.

5. How Peelable Gaskets Work: A Technical Overview

To understand the benefits of peelable gaskets, it is essential to grasp how they work.

5.1 Material Composition and Design

Peelable gaskets are typically made from high-performance materials such as silicone, rubber, or specialized polymer blends. These materials provide superior elasticity, temperature resistance, and compressibility, ensuring an effective seal under various operating conditions.

5.2 Installation Process

The installation process for peelable gaskets is straightforward. Technicians simply peel back a layer to expose the adhesive side and apply it to the designated sealing surface. Once in place, the gasket can be compressed and secured, forming a tight seal that can be easily removed when necessary.

6. Choosing the Right Peelable Gasket for Your Needs

Selecting the appropriate peelable gasket requires careful consideration of several factors, including material compatibility, operational temperature, and pressure conditions. Consulting with gasket manufacturers can provide valuable insights tailored to your specific requirements.

7. Common Misconceptions About Peelable Gaskets

Despite their advantages, several misconceptions surround peelable gaskets. One common myth is that they are less durable than traditional gaskets. In reality, when made from high-quality materials, peelable gaskets can offer comparable or even superior durability, making them an excellent choice for challenging environments.

8. Frequently Asked Questions

1. What industries commonly use peelable gaskets?

Peelable gaskets are widely used in manufacturing, automotive, food processing, and chemical industries, among others.

2. Are peelable gaskets reusable?

Generally, peelable gaskets are designed for single use; however, some high-quality variants may be suitable for limited reuse, depending on the material.

3. How do I know if a peelable gasket is right for my application?

It is essential to consider factors such as material compatibility, operating temperature, and pressure conditions to determine the suitability of a peelable gasket for your application.

4. Can peelable gaskets be used in high-temperature environments?

Yes, peelable gaskets made from heat-resistant materials can effectively perform in high-temperature environments.

5. What is the installation time for peelable gaskets?

Installation time is minimal, typically requiring just a few minutes, thanks to their straightforward design.

9. Conclusion

Peelable gaskets are a game-changing solution for enhancing equipment performance across various industrial sectors. Their unique properties not only improve sealing capabilities but also offer cost and time efficiencies that can significantly bolster operational effectiveness. By integrating peelable gaskets into your machinery, you can achieve a higher level of performance, reliability, and safety. As industries continue to evolve, embracing innovative solutions like peelable gaskets will be key to maintaining a competitive edge.

Related News