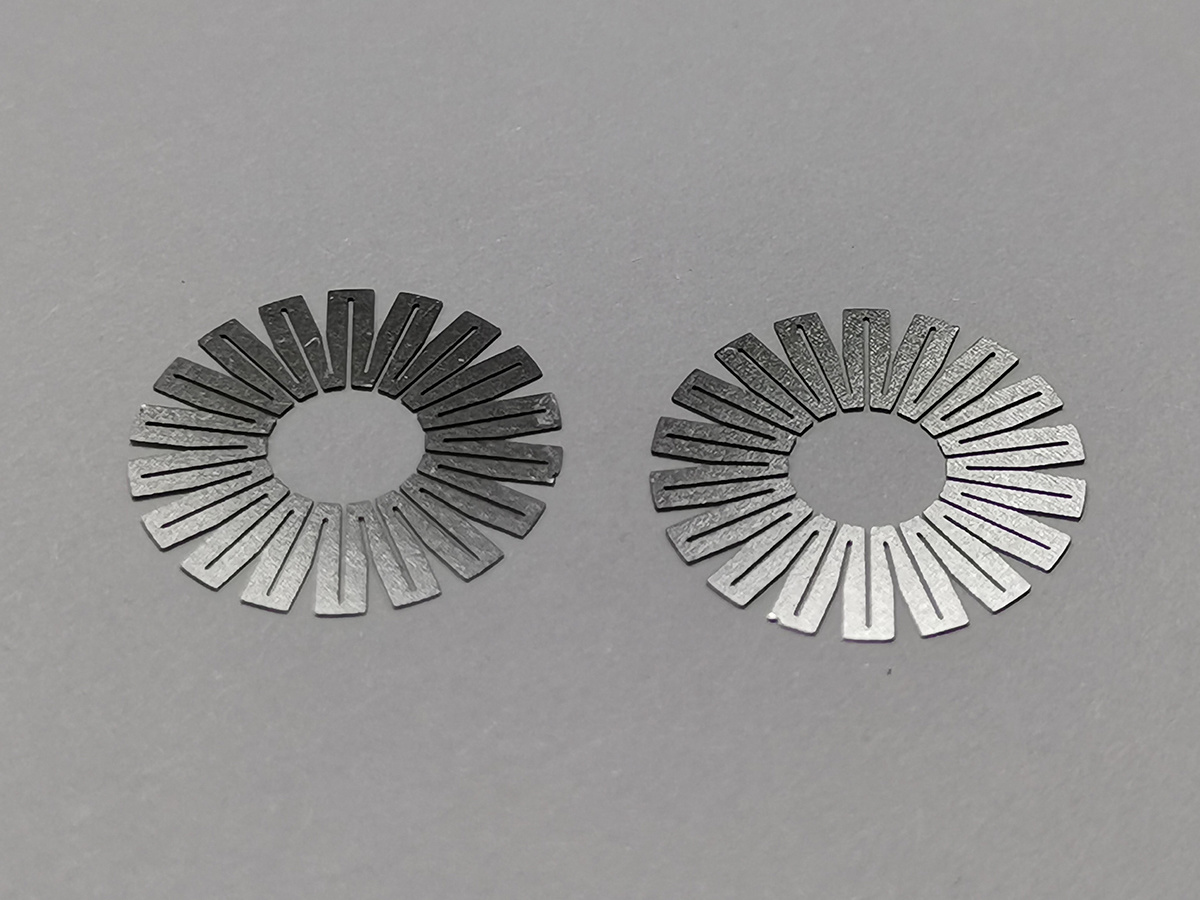

Introduction to 304 Stainless Steel Etching Mesh

In the realm of water spray projects, selecting the right materials is crucial for achieving desired performance and longevity. Among the myriad of options available, **304 stainless steel etching mesh** stands out for its exceptional properties. This article delves into the reasons why you should consider 304 stainless steel etching mesh for your next water spray project.

The Composition and Properties of 304 Stainless Steel

Before diving into the advantages of using 304 stainless steel etching mesh, it is important to understand the composition of 304 stainless steel itself. This alloy primarily consists of:

- **Iron**: The base metal that forms the structure.

- **Chromium (18%)**: Enhances corrosion resistance and durability.

- **Nickel (8%)**: Adds to the metal's toughness and ability to withstand extreme temperatures.

The combination of these elements gives 304 stainless steel its remarkable **corrosion resistance**, **high tensile strength**, and **versatility** in various environments.

Key Properties of 304 Stainless Steel

1. **Corrosion Resistance**: 304 stainless steel is highly resistant to oxidation and corrosion, making it ideal for projects that involve water spraying. The chromium content forms a protective layer over the surface, preventing rust and degradation over time.

2. **Durability**: The strength of this alloy allows it to withstand challenging conditions, including high pressure and temperature fluctuations. This durability is crucial for long-lasting performance in water spray applications.

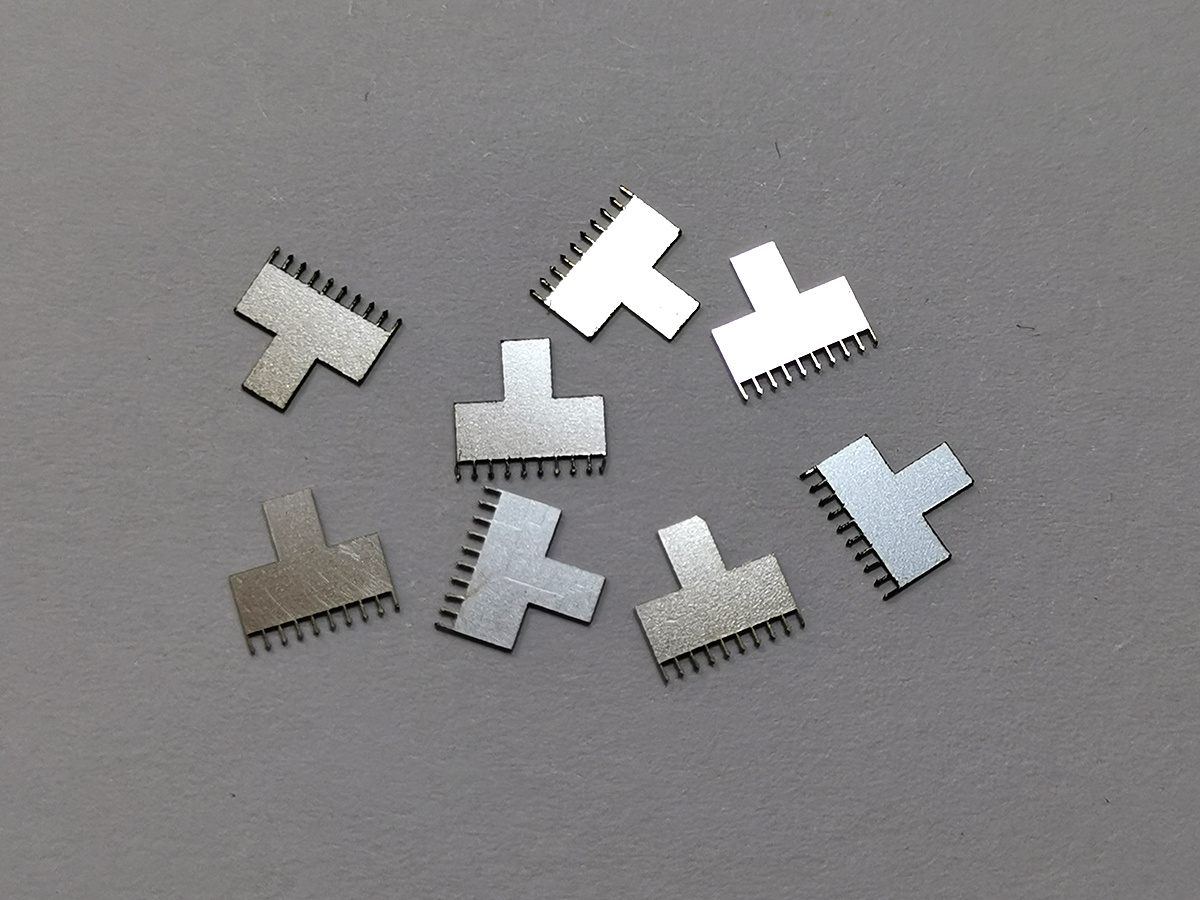

3. **Ease of Fabrication**: The malleability of 304 stainless steel makes it easy to work with, enabling the production of intricate designs and customized sizes.

Why Use Etching Mesh in Water Spray Systems?

Etching mesh, characterized by its unique patterns and structures, offers distinct advantages in water spray projects. Here’s why this type of mesh is particularly suited for such applications:

1. Enhanced Water Distribution

The intricate patterns in etching mesh facilitate optimal water distribution. This uniformity ensures that water reaches every area of the targeted surface, enhancing efficiency in spraying applications.

2. Lightweight and Efficient

Despite its strength, etching mesh is relatively lightweight, which simplifies installation and maintenance. This makes it particularly appealing for large-scale water spray systems where heavy materials may pose challenges.

3. Adjustable Spray Patterns

304 stainless steel etching mesh can be customized to create various spray patterns based on project requirements. This versatility allows for tailored solutions that can address specific spraying needs, optimizing performance.

Applications of 304 Stainless Steel Etching Mesh in Water Spray Projects

304 stainless steel etching mesh finds application in a variety of water spray projects. Here are some noteworthy examples:

1. Agricultural Spraying Systems

In agriculture, consistent and even water distribution is critical for crop health. The use of 304 stainless steel etching mesh in irrigation systems promotes efficient watering practices, leading to healthier crops and better yields.

2. Industrial Cooling Systems

Industrial sectors often require cooling systems that efficiently regulate temperatures. The durability and corrosion resistance of 304 stainless steel make it an ideal choice for spray nozzles and cooling towers, ensuring longevity and reliability.

3. Environmental Applications

In environmental management, 304 stainless steel etching mesh is employed in systems designed for dust suppression and air quality improvement. Its ability to withstand harsh conditions while providing effective spraying solutions makes it invaluable in these scenarios.

Benefits of Choosing 304 Stainless Steel Etching Mesh

When it comes to selecting materials for water spray projects, opting for 304 stainless steel etching mesh comes with a plethora of benefits:

1. Longevity and Cost-Effectiveness

Investing in high-quality materials like **304 stainless steel** ensures longer service life, reducing the need for frequent replacements. This translates to cost savings in both materials and maintenance over time.

2. Eco-Friendly Option

Given its durability, 304 stainless steel contributes to sustainable practices by minimizing waste and resource consumption. Choosing this material aligns with environmentally conscious approaches in project design.

3. Aesthetic Appeal

Etching mesh offers not only functional advantages but also aesthetic benefits. The unique patterns can enhance the overall appearance of a project, adding an element of sophistication and design appeal.

Installation Considerations for 304 Stainless Steel Etching Mesh

To ensure optimal performance of 304 stainless steel etching mesh in your water spray project, certain installation considerations should be kept in mind:

1. Proper Sizing and Fitting

Before installation, ensure that the mesh is appropriately sized for your specific project requirements. Accurate fitting is essential for optimal water distribution and system performance.

2. Regular Maintenance

Although 304 stainless steel is resistant to corrosion, regular inspections and maintenance will prolong its lifespan. Checking for blockages and cleaning the mesh periodically can prevent performance issues.

3. Environmental Factors

Consider the environmental conditions in which the mesh will be installed. Factors such as temperature extremes, humidity levels, and exposure to chemicals can influence the longevity and effectiveness of the stainless steel mesh.

FAQs About 304 Stainless Steel Etching Mesh

1. What is the main advantage of using 304 stainless steel for water spray projects?

The primary advantage of using 304 stainless steel is its remarkable corrosion resistance, which ensures longevity and performance in environments where water and moisture are prevalent.

2. Can 304 stainless steel etching mesh be customized?

Yes, 304 stainless steel etching mesh can be customized to create various spray patterns and mesh sizes, allowing for tailored solutions to meet specific project needs.

3. How does the cost of 304 stainless steel compare to other materials?

While 304 stainless steel may have a higher upfront cost compared to some alternatives, its durability and long service life often make it a more cost-effective option in the long run.

4. Is 304 stainless steel suitable for outdoor applications?

Absolutely. 304 stainless steel is highly resistant to the elements, making it suitable for both indoor and outdoor applications, including harsh environmental conditions.

5. How do I maintain 304 stainless steel etching mesh?

Regular cleaning and inspection are recommended to ensure optimal performance. Removing any build-up or blockages and checking for wear will help maintain the mesh's integrity.

Conclusion

In conclusion, **304 stainless steel etching mesh** is an exceptional choice for any water spray project due to its durability, corrosion resistance, and versatility. Its unique properties not only enhance performance but also contribute to the longevity of your project. By understanding the numerous benefits and applications of 304 stainless steel etching mesh, you can make an informed decision that will ensure the success of your water spray endeavors. Embrace the advantages of this material and elevate your project with confidence!

Related News