13

2025-11

In the automotive industry, Electromagnetic Interference (EMI) is a growing concern due to the increasing complexity of electronic systems in vehicles. To mitigate these issues, Automotive EMI Shielding Conductive Sheets have become essential components. These sheets are designed to prevent unwanted electromagnetic signals from disrupting the operation of sensitive electronic components, such as those found in modern vehicles.

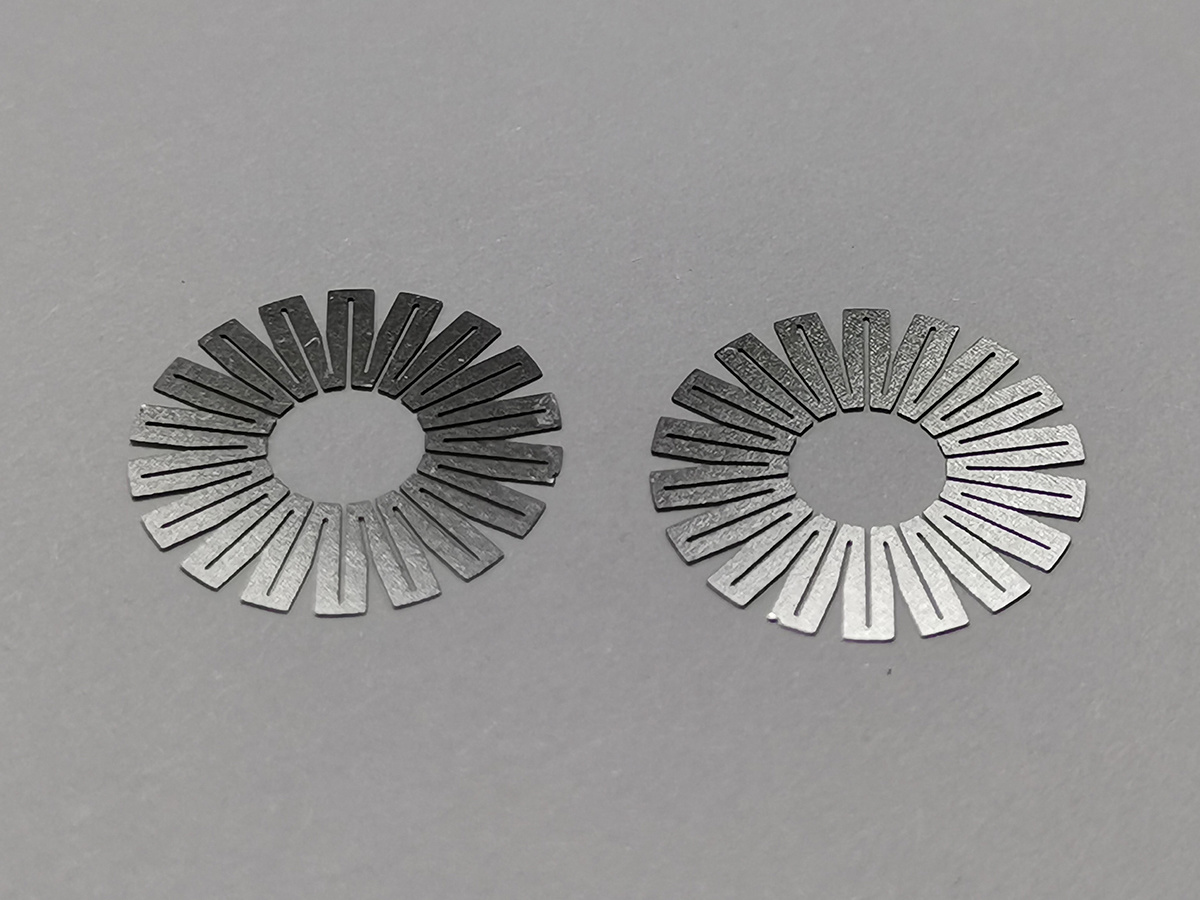

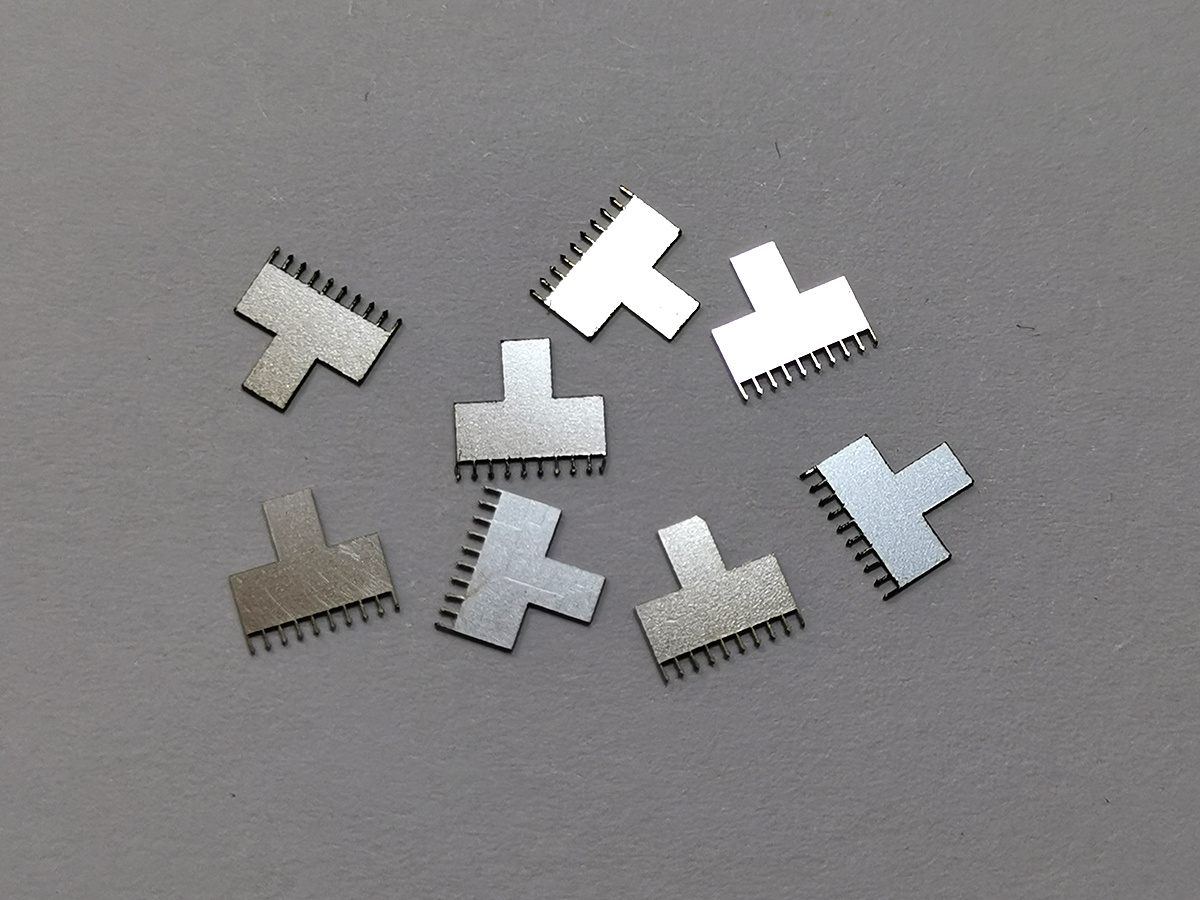

Automotive EMI Shielding Conductive Sheets are typically made from conductive materials, which can include metals or specially formulated conductive polymers. These sheets serve as barriers that absorb or reflect electromagnetic waves, thereby maintaining the integrity and functionality of electronic systems. Their application is crucial in various parts of a vehicle, including the engine control unit (ECU), infotainment systems, and advanced driver-assistance systems (ADAS).

One of the primary benefits of using these conductive sheets is their ability to enhance signal integrity. In a world where vehicles are becoming increasingly reliant on electronic communication, ensuring that signals are transmitted without interference is paramount. By integrating Automotive EMI Shielding Conductive Sheets, manufacturers can minimize the risk of signal degradation caused by external electromagnetic sources, such as RF transmissions or other nearby electronic devices.

Moreover, the use of these conductive sheets contributes to the overall safety and reliability of automotive systems. As vehicles evolve to incorporate more features, including electric and hybrid powertrains, the need for effective shielding becomes even more pronounced. EMI shielding helps protect sensitive components from potential damage caused by electromagnetic exposure, thus enhancing the lifespan and performance of the vehicle.

In addition to their protective capabilities, Automotive EMI Shielding Conductive Sheets can also be customized to meet specific design requirements. This flexibility allows manufacturers to optimize their shielding solutions according to the unique challenges posed by different vehicle models or electronic configurations. Whether it’s achieving a specific thickness, form factor, or conductivity level, these sheets can be tailored to ensure maximum effectiveness.

From a chemical perspective, the development of high-performance conductive paints used in these sheets has advanced significantly. Innovations in formulations have led to improvements in conductivity, durability, and environmental resistance. This evolution is crucial as the automotive sector increasingly emphasizes sustainability and eco-friendly practices.

In conclusion, Automotive EMI Shielding Conductive Sheets play a vital role in the modern automotive landscape, ensuring that vehicles can operate effectively in an increasingly electronic environment. By understanding their importance and applications, professionals within the coating and conductive paint industry can better appreciate the role these materials play in enhancing vehicle performance and safety. As the automotive sector continues to advance, staying informed about these technologies will be essential for industry professionals aiming to remain competitive and innovative.

Automotive EMI Shielding Conductive Sheets are typically made from conductive materials, which can include metals or specially formulated conductive polymers. These sheets serve as barriers that absorb or reflect electromagnetic waves, thereby maintaining the integrity and functionality of electronic systems. Their application is crucial in various parts of a vehicle, including the engine control unit (ECU), infotainment systems, and advanced driver-assistance systems (ADAS).

One of the primary benefits of using these conductive sheets is their ability to enhance signal integrity. In a world where vehicles are becoming increasingly reliant on electronic communication, ensuring that signals are transmitted without interference is paramount. By integrating Automotive EMI Shielding Conductive Sheets, manufacturers can minimize the risk of signal degradation caused by external electromagnetic sources, such as RF transmissions or other nearby electronic devices.

Moreover, the use of these conductive sheets contributes to the overall safety and reliability of automotive systems. As vehicles evolve to incorporate more features, including electric and hybrid powertrains, the need for effective shielding becomes even more pronounced. EMI shielding helps protect sensitive components from potential damage caused by electromagnetic exposure, thus enhancing the lifespan and performance of the vehicle.

In addition to their protective capabilities, Automotive EMI Shielding Conductive Sheets can also be customized to meet specific design requirements. This flexibility allows manufacturers to optimize their shielding solutions according to the unique challenges posed by different vehicle models or electronic configurations. Whether it’s achieving a specific thickness, form factor, or conductivity level, these sheets can be tailored to ensure maximum effectiveness.

From a chemical perspective, the development of high-performance conductive paints used in these sheets has advanced significantly. Innovations in formulations have led to improvements in conductivity, durability, and environmental resistance. This evolution is crucial as the automotive sector increasingly emphasizes sustainability and eco-friendly practices.

In conclusion, Automotive EMI Shielding Conductive Sheets play a vital role in the modern automotive landscape, ensuring that vehicles can operate effectively in an increasingly electronic environment. By understanding their importance and applications, professionals within the coating and conductive paint industry can better appreciate the role these materials play in enhancing vehicle performance and safety. As the automotive sector continues to advance, staying informed about these technologies will be essential for industry professionals aiming to remain competitive and innovative.

Related News